- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Communication Skills - Active and skillful listening

By Mastermind Academy UK Ltd

Communication is the exchange of information, ideas, and feelings effectively between individuals. It encompasses various forms, including verbal, written, and non-verbal (body) language. This course is designed to provide you with the essential skills necessary to communicate confidently.

Communication Skills - There's power in your voice

By Mastermind Academy UK Ltd

Communication is the exchange of information, ideas, and feelings effectively between individuals. It encompasses various forms, including verbal, written, and non-verbal (body) language. This course is designed to provide you with the essential skills necessary to communicate confidently.

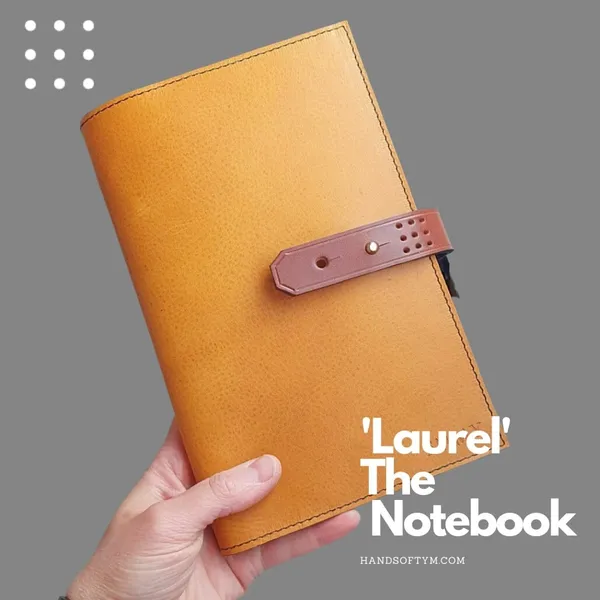

Laurel is the essence of personalised ease and style. The perfect gift for the budding writer or professional in your life - maybe that’s you. Never miss a meeting or big idea with this refillable leather diary / notebook cover (A5) that fits easily into a bag or briefcase. Laurel features a contrasting adjustable strap with stud fastening to keep your work secure, and two internal card slots perfect for business meetings. Choose your preferred English hand bound paper insert: Plain or lined notebook, or week to view diary. There are 9 leather colours to choose from, 2 leather colour straps and gold or silver hardware. Make it your own with bespoke personalisation. If you’re gifting Laurel, a personalised message can be embossed to the bottom right corner (as standard), but get in touch if you have other requests.(This is +£5) Size and DetailsSlim A5 (Quarto Medium) removable leather notebook or diary cover Paper size: 210mm x 135mm Thickness: 120 pages Cover size: 225mm x 145mm x 20mm 1x insert included Made to order and available in multiple colours with contrasting strap. Timeless designFront strap features the Hands of Tym logo. Made from respectfully-sourced Italian vegetable-tanned leather (biodegradable). Hand cut. Handmade. Hand finished. Other Sizes Available:Slim A4 (Folio Large)Slim A6 (Octavo Pocket)REFILL PAD available Personalisation & Unique stamp (not available for Courses or Tools & Supplies) What is personalisation? Personalisation is an embossed stamp of characters including letters, emojis etc. Please select from the options below if you would like to add to your product. What is a Unique Stamp? A unique stamp is a custom stamp made up of an image of your choice. It can be handprints, a drawing, handwriting etc. We can discuss this with you once you place your order. (This is +£45) How this was made Made from respectfully-sourced Italian vegetable-tanned leather, Laurel is free from harsh chemicals. Over time the luxury leather will develop a buttery soft patina. The paper inserts are hand-bound by experienced artisans in England from a quality British paper. Laurel has been thoughtfully designed and handmade by Hands of Tym, in Oxfordshire, England. Material and CareMaterialsHere at Hands of Tym, we are passionate about sourcing the highest quality sustainable materials. We use responsibly-sourced Italian vegetable-tanned leather. Find out more here.Using only the highest quality cuts, the leather will improve with use and age, developing a soft patina over time. Natural variations are a product feature of this material and contribute to the individual style of the product.The leather is free from harmful chemicals and biodegradable at the end of its life.Hand cut, handmade and hand finished in our workshop in Oxfordshire, England. Care Please note: There may be natural changes in the colour of the materials and they may stain easily. Please be careful with oils and inks. When not in use, store your product in the soft cloth bag (provided) in a cool and dry place. Repair When you buy from Hands of Tym, you’re getting so much more than your new purchase. You’re creating a connection with the maker - Georgie Tym. If your leather product becomes damaged (afterall, life happens), contact us to find out about repairing your item. What's included in the price? Laurel arrives complete with one insert and additional inserts can be purchased directly from us. Laurel arrives wrapped in tissue paper inside a black cotton dust bag, including a 'Made for you' card with care instructions and a unique code to identify your handmade leather notebook cover.

Kent Test Tutoring

By Top Dog Tutoring

Our twice-weekly sessions help take the stress away from Kent Test (11+) preparation. With each group led by a dedicated, fully-qualified primary school teacher, you can be safe in the knowledge that your child is receiving expert tuition as well as relevant test-style questioning. Our bespoke curriculum is designed to cover English, maths and reasoning, guaranteeing complete coverage that gives your child all the familiarisation they need before test day.

Understanding Autism - Level 3

By Training Tale

This Understanding Autism - Level 3 allows you to acquire new skills and expand your professional knowledge from the comfort of your own home at your own speed. This course has been expertly created for you to complete through distance e-learning and achieve a professional certificate without leaving your house! This course covers comprehensive lessons that will provide you with valuable information about the difficulties related to autism, how you might help someone diagnosed with autism spectrum disorders, and how to raise autism awareness. Autism symptoms can vary from mild to severe, and this course will guide you through the screening and diagnosing process step by step. You will also gain important communication skills that will be beneficial to those working in special education. Enrol in our Understanding Autism - Level 3 course today to gain access to high-quality training modules covering a wide range of important topics that will help you get your dream job! Learning Outcomes After completing this Understanding Autism - Level 3 course, you will be able to: Communicate with people who have autism and interact with them socially. Assist and manage transitions for people with autism. Provide positive behavioural support to people with autism. Explain the therapeutic approaches and resources available to people with autism and co-occurring disorders. Why Choose Understanding Autism - Level 3 Bundle Course from Us Self-paced course, access available from anywhere. Easy to understand, high-quality study materials. Course developed by industry experts. MCQ quiz after each module to assess your learning. Automated and instant assessment results. Free PDF certificate as soon as completing the Understanding Autism course. 24/7 support via live chat, phone call or email. ***Courses are included in this Understanding Autism - Level 3 course Course 01: Understanding Autism Course 02: Level 2 Certificate in Behaviour that Challenges in Children Course 03: Primary Teaching Diploma Course 04: Level 4 Diploma in Child Counselling Course Course 05: Child and Adolescent Mental Health Course Course 06: Child Protection and Risk Assessment Course 07: Level 3 Award in Childcare and Education Course Course 08: Level 4 Child Care and Development Course Course 09: Level 2 Safeguarding Children Training Course Course 10: Level 1 Award in Working with Children Course 11: Level 2 Award in Babysitting Course 12: Level 2 Award in Support Work in Schools and Colleges Course 13: Advanced Diploma in Child Care Course 14: Level 2 Certificate in Understanding Common Childhood Illnesses Affecting Children Course 15: Level 2 Certificate in Behaviour that Challenges in Children ***Other Benefits of Understanding Autism - Level 3 Bundle course Free 15 PDF Certificate Lifetime Access Free Retake Exam Tutor Support [ Note: Free PDF certificate as soon as completing the Understanding Autism - Level 3 Bundle course] Course Curriculum of- ***Understanding Autism - Level 3*** [ Bundle Course 01] Module 1: Autism in Context The Historical Context of Autism The Diagnosis and Characteristics of Autism The Legislative Framework Applicable to Autism How Autism is Represented in Society Module 2: Positive Behavioural Support for Individuals with Autism Behaviour within the Context of Autism How to Promote an Autism-friendly Environment How to Promote Individual Positive Behavioural Support Interventions Used in Behavioural Support Module 3: Understand Support and Management of Transitions for Individuals with Autism How Transitions Can Affect People with Autism How to Support Young People with Autism to Make the Transition into Adulthood How to Support Individuals with Autism into Employment Module 4: Therapeutic Interventions and Support Available for Individuals with Autism and Co-occurring Conditions The Range of Therapeutic Interventions Available to Individuals with Autism The Services Available to Individuals with Autism and Their Families Co-occurring Conditions and Their Treatment Module 5: Communication and Social Interaction with Individuals with Autism Differences in Social Interaction and Communication Associated with Autism How Own Communication Can be Adapted to Support Positive Interactions and Communication with Individuals with Autism A Range of Strategies and Aids Used to Support Communication and Social Interaction for Individuals with Autism Module 6: Safeguarding and Resilience in Autism How to Raise Concerns about Potential or Actual Harm, Abuse or Exploitation How to Support the Health, Safety and Well-being of Individuals How the Legislative Framework Safeguards Children, Young People and Adults with Autism How and When Restrictive Practices Might be Used within Legal Guidelines Assessment Method After completing each module of the Understanding Autism - Level 3 Course, you will find automated MCQ quizzes. To unlock the next module, you need to complete the quiz task and get at least 60% marks. Certification After completing the MCQ/Assignment assessment for this course, you will be entitled to a Certificate of Completion from Training Tale. The certificate is in PDF format, which is completely free to download. A printed version is also available upon request. It will also be sent to you through a courier for £13.99. Who is this course for? This Understanding Autism - Level 3 course is ideal for - Teacher Parents Students Fresh Graduates Nurses Child Minders Care Home Professionals Anyone who is already working in this sector Requirements Students who intend to enrol in this Understanding Autism - Level 3 course must meet the following requirements: Good command of the English language Must be vivacious and self-driven Basic computer knowledge A minimum of 16 years of age is required Career path This Understanding Autism - Level 3 Course will lead to a competitive advantage and open the door to a wide range of career opportunities. Certificates Certificate of completion Digital certificate - Included

Young Peoples Mental Health Level 2

By Training Tale

One out of every ten children and young people suffers from mental health issues. These issues include depression, anxiety, and conduct disorder and can often directly respond to circumstances in their lives. The Young Peoples Mental Health Level 2 course aims to provide you with a more in-depth understanding of mental health conditions that affect children and young people, mental health legislation and guidance, risk factors that may affect mental well-being, and the impact that mental health concerns may have on young people and others. Enrol today and get started on your journey to improve your career prospects with the latest skills and the power of self-belief! Learning Outcomes By the end of this Young Peoples Mental Health Level 2 course, the learner will be able to: Understand the concept of children and young people's Mental Health. Explain factors that may affect children and young people's Mental Health. Understand Children and Young People's Mental Health Concerns. Know the Impact of Children and Young People's Mental Health Concerns. Support Children and Young People with Mental Health Concerns. Why Choose this Young Peoples Mental Health Level 2 Course from Us Self-paced course, access available from anywhere. Easy to understand, high-quality study materials. Course developed by industry experts. MCQ quiz after each module to assess your learning. Automated and instant assessment results. 24/7 support via live chat, phone call or email. Free PDF certificate as soon as completing the course. ----------------------- Other 14 courses that are included with our Young Peoples Mental Health Level 2 Bundle Course Course 01: Drug and Alcohol Awareness Training Course 02: Level 2 Certificate in Understanding the Safe Handling of Medication in Health and Social Care Course 03: Level 5 Mental Health First Aid Certification Course 04: Level 3 Diploma in Healthcare Support Course 05: Level 5 Mental Health Care - MCA and DOLS Course 06: Level 2 Award in Awareness of Dementia Course 07: Level 2 Certificate in Preparing to Work in Adult Social Care Course 08: Level 5 Diploma in Family Support Worker Course 09: Level 3 Award in Health and Social Care Course Course 10: Level 2 Youth Work Certificate Course Course 11: Level 2 Safeguarding Children Training Course Course 12: Equality and Diversity Course 13: Diploma in Mastering Psychology Course 14: Mental Health Support Worker Others Benefits of this Young Peoples Mental Health Level 2 Bundle Course Free 15 PDF Certificate Access to Content - Lifetime Exam Fee - Totally Free Free Retake Exam [Note: Free PDF certificate will be provided as soon as the Young Peoples Mental Health Level 2 Course is completed] Course Curriculum Module 1: Understand Children and Young People's Mental Health in Context Module 2: Understand Factors Which May Affect Children and Young People's Mental Health Module 3: Understand Children and Young People's Mental Health Concerns Module 4: Understand the Impact of Children and Young people's Mental Health Concerns Module 5: Understand How to Support Children and Young People with Mental Health Concerns Assessment Method After completing each module of the Young Peoples Mental Health Level 2 Course, you will find automated MCQ quizzes. To unlock the next module, you need to complete the quiz task and get at least 60% marks. Certification After completing the MCQ/Assignment assessment for this Young Peoples Mental Health Level 2 course, you will be entitled to a Certificate of Completion from Training Tale. The certificate is in PDF format, which is completely free to download. A printed version is also available upon request. It will also be sent to you through a courier for £13.99. Who is this course for? This comprehensive online Young Peoples Mental Health Level 2 course is ideal for people seeking a qualification to help them increase their knowledge of mental health in children and young people for personal reasons or to support progression onto further qualifications and into relevant employment in the health and social care or education sectors. Requirements There are no specific requirements for this Young Peoples Mental Health Level 2 bundle course because it does not require any advanced knowledge or skills. Students who intend to enroll in this Young Peoples Mental Health Level 2 course must meet the following requirements: Good command of the English language Must be vivacious and self-driven Basic computer knowledge A minimum of 16 years of age is required Career path Anyone who wishes to begin a career in childcare, teaching, or working with people who have mental health problems should take this Young Peoples Mental Health Level 2 course. Certificates Certificate of completion Digital certificate - Included

Business Law

By SkillWise

Overview Uplift Your Career & Skill Up to Your Dream Job - Learning Simplified From Home! Kickstart your career & boost your employability by helping you discover your skills, talents, and interests with our special Business Law Course. You'll create a pathway to your ideal job as this course is designed to uplift your career in the relevant industry. It provides the professional training that employers are looking for in today's workplaces. The Business Law Course is one of the most prestigious training offered at Skillwise and is highly valued by employers for good reason. This Business Law Course has been designed by industry experts to provide our learners with the best learning experience possible to increase their understanding of their chosen field. This Business Law Course, like every one of Skillwise's courses, is meticulously developed and well-researched. Every one of the topics is divided into elementary modules, allowing our students to grasp each lesson quickly. At Skillwise, we don't just offer courses; we also provide a valuable teaching process. When you buy a course from Skillwise, you get unlimited Lifetime access with 24/7 dedicated tutor support. Why buy this Business Law? Unlimited access to the course forever Digital Certificate, Transcript, and student ID are all included in the price Absolutely no hidden fees Directly receive CPD Quality Standard-accredited qualifications after course completion Receive one-to-one assistance every weekday from professionals Immediately receive the PDF certificate after passing Receive the original copies of your certificate and transcript on the next working day Easily learn the skills and knowledge from the comfort of your home Certification After studying the course materials of the Business Law there will be a written assignment test which you can take either during or at the end of the course. After successfully passing the test you will be able to claim the pdf certificate for free. Original Hard Copy certificates need to be ordered at an additional cost of £8. Who is this course for? This Business Law course is ideal for Students Recent graduates Job Seekers Anyone interested in this topic People already working in the relevant fields and want to polish their knowledge and skills. Prerequisites This Business Law does not require you to have any prior qualifications or experience. You can just enroll and start learning. This Business Law was made by professionals and it is compatible with all PCs, Macs, tablets, and smartphones. You will be able to access the course from anywhere at any time as long as you have a good enough internet connection. Career path As this course comes with multiple courses included as a bonus, you will be able to pursue multiple occupations. This Business Law is a great way for you to gain multiple skills from the comfort of your home. Module 1: Understanding Business Law Understanding Business Law 00:20:00 Module 2: European Community Law European Community Law 00:19:00 Module 3: The Court System The Court System 00:36:00 Module 4: Civil and Alternative Dispute Resolution Civil and Alternative Dispute Resolution 00:22:00 Module 5: Contract & Business Law Contract & Business Law 00:43:00 Module 6: Employment Law Employment Law 00:24:00 Module 7: Agency Law Agency Law 00:17:00 Module 8: Consumer Law and Protection Consumer Law and Protection 00:26:00 Module 9: Law of Tort Law of Tort 00:29:00 Module 10: Business Organisations Business Organisations 00:27:00 Module 11: Company Law Company Law 00:25:00 Module 12: Business Property Business Property 00:23:00 Module 13: Competition Law Competition Law 00:22:00 Assignment Assignment - Business Law 07:41:00

Business Startup

By SkillWise

Overview Uplift Your Career & Skill Up to Your Dream Job - Learning Simplified From Home! Kickstart your career & boost your employability by helping you discover your skills, talents, and interests with our special Business Startup Course. You'll create a pathway to your ideal job as this course is designed to uplift your career in the relevant industry. It provides the professional training that employers are looking for in today's workplaces. The Business Startup Course is one of the most prestigious training offered at Skillwise and is highly valued by employers for good reason. This Business Startup Course has been designed by industry experts to provide our learners with the best learning experience possible to increase their understanding of their chosen field. This Business Startup Course, like every one of Skillwise's courses, is meticulously developed and well-researched. Every one of the topics is divided into elementary modules, allowing our students to grasp each lesson quickly. At Skillwise, we don't just offer courses; we also provide a valuable teaching process. When you buy a course from Skillwise, you get unlimited Lifetime access with 24/7 dedicated tutor support. Why buy this Business Startup? Unlimited access to the course forever Digital Certificate, Transcript, and student ID are all included in the price Absolutely no hidden fees Directly receive CPD Quality Standard-accredited qualifications after course completion Receive one-to-one assistance every weekday from professionals Immediately receive the PDF certificate after passing Receive the original copies of your certificate and transcript on the next working day Easily learn the skills and knowledge from the comfort of your home Certification After studying the course materials of the Business Startup there will be a written assignment test which you can take either during or at the end of the course. After successfully passing the test you will be able to claim the pdf certificate for free. Original Hard Copy certificates need to be ordered at an additional cost of £8. Who is this course for? This Business Startup course is ideal for Students Recent graduates Job Seekers Anyone interested in this topic People already working in the relevant fields and want to polish their knowledge and skills. Prerequisites This Business Startup does not require you to have any prior qualifications or experience. You can just enroll and start learning. This Business Startup was made by professionals and it is compatible with all PCs, Macs, tablets, and smartphones. You will be able to access the course from anywhere at any time as long as you have a good enough internet connection. Career path As this course comes with multiple courses included as a bonus, you will be able to pursue multiple occupations. This Business Startup is a great way for you to gain multiple skills from the comfort of your home. Section-1: Adonis Business Model - The Model of Successful Businesses Stop The Excuses and Start Your Own Business 00:12:00 Why You Should Start Your Own Business 00:05:00 What Is Required to Start Your Own Business 00:10:00 Explanation of The Adonis Business Model 00:08:00 Decisions That You Should Take Today 00:03:00 The Market Pyramid and How It Affects Your Sales 00:12:00 Massive Vital Actions for Accelerate Business Growth 00:09:00 Section-2: Creation of A Business Idea How to Create a Successful Business Idea 00:09:00 Creation of a Successful Action Plan 00:06:00 How to Create Products/Services That People Would Like to Buy 00:02:00 Creation of Sustainable Competitive Advantages 00:10:00 The TAPA Method - The Best Way to Present Your Products and Services. 00:16:00 Section-3: Building A Successful Brand How to Create a Successful Brand 00:18:00 Section-4: Active Sales The 4 C's That Will Increase Your Sales 00:13:00 Organizing Your Meetings 00:11:00 How to Set Up Appointments with Potential Customers 00:19:00 The 8 Steps of The Sale Process That Will Maximize Your Success. 00:17:00 How to Do Educational-Sales 00:12:00 Section-5: Passive Sales How to Sell Through the Internet 00:09:00 How to Generate Traffic to Your Website for Maximum Online Sales 00:02:00 Promoting Your Business Through Social Media 00:08:00 The Right Structure for Your Website for Online Sales. 00:09:00 Section-6: Create A Business and Action Plan Create a Business and Action Plan 00:04:00 Assignment Assignment - Business Startup 06:16:00

Physiotherapy

By SkillWise

Overview Uplift Your Career & Skill Up to Your Dream Job - Learning Simplified From Home! Kickstart your career & boost your employability by helping you discover your skills, talents, and interests with our special Physiotherapy Course. You'll create a pathway to your ideal job as this course is designed to uplift your career in the relevant industry. It provides the professional training that employers are looking for in today's workplaces. The Physiotherapy Course is one of the most prestigious training offered at Skillwise and is highly valued by employers for good reason. This Physiotherapy Course has been designed by industry experts to provide our learners with the best learning experience possible to increase their understanding of their chosen field. This Physiotherapy Course, like every one of Skillwise's courses, is meticulously developed and well-researched. Every one of the topics is divided into elementary modules, allowing our students to grasp each lesson quickly. At Skillwise, we don't just offer courses; we also provide a valuable teaching process. When you buy a course from Skillwise, you get unlimited Lifetime access with 24/7 dedicated tutor support. Why buy this Physiotherapy? Unlimited access to the course forever Digital Certificate, Transcript, and student ID are all included in the price Absolutely no hidden fees Directly receive CPD Quality Standard-accredited qualifications after course completion Receive one-to-one assistance every weekday from professionals Immediately receive the PDF certificate after passing Receive the original copies of your certificate and transcript on the next working day Easily learn the skills and knowledge from the comfort of your home Certification After studying the course materials of the Physiotherapy there will be a written assignment test which you can take either during or at the end of the course. After successfully passing the test you will be able to claim the pdf certificate for free. Original Hard Copy certificates need to be ordered at an additional cost of £8. Who is this course for? This Physiotherapy course is ideal for Students Recent graduates Job Seekers Anyone interested in this topic People already working in the relevant fields and want to polish their knowledge and skills. Prerequisites This Physiotherapy does not require you to have any prior qualifications or experience. You can just enroll and start learning. This Physiotherapy was made by professionals and it is compatible with all PCs, Macs, tablets, and smartphones. You will be able to access the course from anywhere at any time as long as you have a good enough internet connection. Career path As this course comes with multiple courses included as a bonus, you will be able to pursue multiple occupations. This Physiotherapy is a great way for you to gain multiple skills from the comfort of your home. Module 01: Introduction to Physiotherapy Introduction to Physiotherapy 00:12:00 Module 02: The Standards for Physiotherapists The Standards for Physiotherapists 00:24:00 Module 03: The Physiotherapy Interventions The Physiotherapy Interventions 00:23:00 Module 04: Sports Physiotherapy Sports Physiotherapy 00:28:00 Module 05: Neurological Physiotherapy Neurological Physiotherapy 00:33:00 Module 06: Musculoskeletal Physiotherapy Musculoskeletal Physiotherapy 00:19:00 Module 07: Respiratory Physiotherapy Respiratory Physiotherapy 00:25:00 Module 08: Paediatric Physiotherapy Paediatric Physiotherapy 00:26:00 Module 09: Evidence-Based Physiotherapy (EBP) Evidence-Based Physiotherapy (EBP) 00:12:00 Module 10: Building a Career as a Physiotherapist Building a Career as a Physiotherapist 00:15:00 Assignment Assignment - Physiotherapy 07:12:00

Supply Chain Management

By SkillWise

Overview Uplift Your Career & Skill Up to Your Dream Job - Learning Simplified From Home! Kickstart your career & boost your employability by helping you discover your skills, talents, and interests with our special Supply Chain Management Course. You'll create a pathway to your ideal job as this course is designed to uplift your career in the relevant industry. It provides the professional training that employers are looking for in today's workplaces. The Supply Chain Management Course is one of the most prestigious training offered at Skillwise and is highly valued by employers for good reason. This Supply Chain Management Course has been designed by industry experts to provide our learners with the best learning experience possible to increase their understanding of their chosen field. This Supply Chain Management Course, like every one of Skillwise's courses, is meticulously developed and well-researched. Every one of the topics is divided into elementary modules, allowing our students to grasp each lesson quickly. At Skillwise, we don't just offer courses; we also provide a valuable teaching process. When you buy a course from Skillwise, you get unlimited Lifetime access with 24/7 dedicated tutor support. Why buy this Supply Chain Management? Unlimited access to the course forever Digital Certificate, Transcript, and student ID are all included in the price Absolutely no hidden fees Directly receive CPD Quality Standard-accredited qualifications after course completion Receive one-to-one assistance every weekday from professionals Immediately receive the PDF certificate after passing Receive the original copies of your certificate and transcript on the next working day Easily learn the skills and knowledge from the comfort of your home Certification After studying the course materials of the Supply Chain Management there will be a written assignment test which you can take either during or at the end of the course. After successfully passing the test you will be able to claim the pdf certificate for free. Original Hard Copy certificates need to be ordered at an additional cost of £8. Who is this course for? This Supply Chain Management course is ideal for Students Recent graduates Job Seekers Anyone interested in this topic People already working in the relevant fields and want to polish their knowledge and skills. Prerequisites This Supply Chain Management does not require you to have any prior qualifications or experience. You can just enroll and start learning. This Supply Chain Management was made by professionals and it is compatible with all PCs, Macs, tablets, and smartphones. You will be able to access the course from anywhere at any time as long as you have a good enough internet connection. Career path As this course comes with multiple courses included as a bonus, you will be able to pursue multiple occupations. This Supply Chain Management is a great way for you to gain multiple skills from the comfort of your home. Module 01: An overview of Supply Chain Management An Overview of Supply Chain Management 00:17:00 Module 02: Role of logistics of Supply Chain Role of logistics of Supply Chain 00:19:00 Module 03: Customer Response Principles and Systems Customer Response Principles and Systems 00:15:00 Module 04: Supply Chain System and Principles Supply Chain System and Principles 00:15:00 Module 05: Global Supply Chain Operations Global Supply Chain Operations 00:17:00 Module 06:Inventory Strategies for Supply Chain Inventory Strategies for Supply Chain 00:15:00 Module 07: Warehouse Management and Operations Warehouse Management and Operations 00:13:00 Module 08: Supply Chain Design and Monitoring Supply Chain Design and Monitoring 00:15:00 Module 09: Supply Chain Network and Evaluating Supply Chain Network and Evaluating 00:18:00 Module 10: Supply Chain Planning and New Business Concepts Supply Chain Planning and New Business Concepts 00:17:00 Module 11: Aligning your supply chain process with your business Aligning Supply Chain Process with Your Business 00:18:00 Mock Exam Final Exam Assignment Assignment - Supply Chain Management 08:01:00 Feedback Learner Feedback