- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

2818 Courses

Motorcycle Wheel Building Masterclass (Online + 4 days of Private 1 to 1 tuition)

4.7(20)By Colwood Wheel Works

The Wheel Building Masterclass with Vince Warner Ready to Elevate Your Wheel Building Skills? Imagine Building Every Wheel with Confidence and Precision. That's What Mastery Feels Like. I started to learn to build wheels in 1967. My dad always said if you can count to 4 you can learn to build wheels, and as soon as I could count to 4 he had to prove to everybody that he was right. I was approaching my 4th birthday when he took me into his workshop and started to show me his trade secrets. I don't for one moment think you need to start at 3 years old to become an excellent wheel builder, but I do believe you need to be shown the techniques clearly by an experienced craftsman. Join Me in My Workshop for the Ultimate Learning Experience. What You'll Gain: Confidence in every wheel you build A high professional standard in all your projects The ability to charge for your expertise (if you wish to) The Masterclass Includes: Full access to all video training modules Personalised instruction from me, Vince Warner 4 full days of intensive training Exclusive private one-to-one attention A certificate showing you have completed the masterclass And Lunch is on Me, Every Day! Enjoy complimentary lunch, along with tea, coffee, cold drinks, and snacks throughout the day.

Barista Skills teaches the essential practical skills needed behind the espresso bar, such as how to set your grinder, make espresso, foam and texture milk for cappuccinos, and create latte art, as well as an exploration of health and safety issues, customer service protocols, and basic business practices. The Barista Skills Intermediate course builds on the concepts and skills introduced in the Foundation course. It is ideal for someone who has barista skills experience and wants to explore how to improve coffee quality and prepare for more complex job functions found in the barista profession. Through this interactive course, learners will gain a deeper understanding of the coffee itself, specifically, the impact of a coffee’s variety, origins and processing methods on flavour; the parameters of coffee quantity, grind texture, water quality, and shot time and their interaction when dialling in a brew recipe; drink construction and taste differences; workflow management and efficiency, sensory aspects of the espresso extraction; milk handling and techniques as well as latte art. In addition to coffee preparation, this course also covers key concepts regarding health and safety, customer service, and basic business practices. A written exam tests Intermediate course knowledge, while a practical exam assesses the learner’s ability in terms of grinder calibration, espresso extraction analysis, latte art skills and drinks construction.

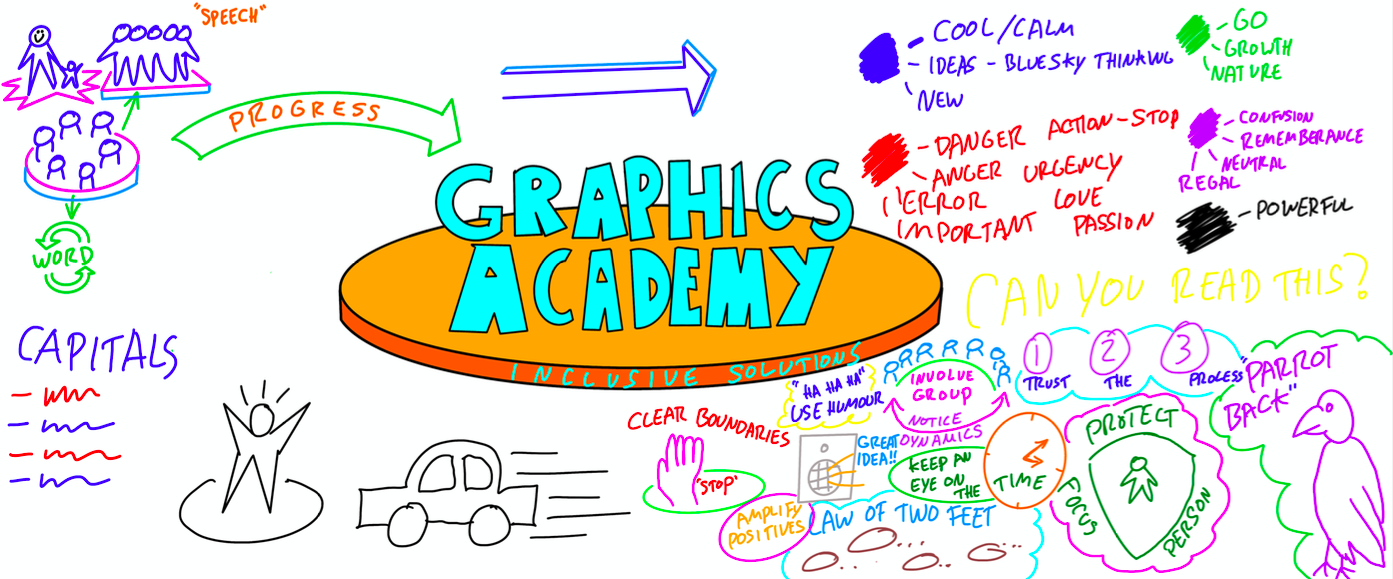

GRAPHIC FACILITATION – AN INTRODUCTION

By Inclusive Solutions

This day will introduce you to the basic techniques and skills involved in doing graphic facilitation. Learn how to use a BIG piece of paper and a handful of pens to create a memorable summary of your training day, team meeting or your work with young people and families. Learn how to harvest the essence of an event in a visual representation. This is a ‘hands on’ interactive day built around demonstrations of graphic facilitation, coaching and the chance to try things out. Ideal for teams who can then go on together to practice, practice, practice. Learning Objectives To introduce you to the basic skills of graphic facilitation – no previous experience is needed To develop your capacity to ‘listen under the words’ and draw out the deeper messages To help you suspend your self-doubt – “I can’t draw!” and rediscover your capacity to create an effective visual representation of a meeting/training day/conversation etc Course Content The day will introduce you to the fundamentals of graphic facilitation and will include the following topics: Pens, Pastels and Paper – what you will need to get started The basic ‘grammar’ of graphic facilitation; the essential shapes, using colour, images, lettering, words, creating connection How to listen for the essence of what is being said and translate this into visual language A chance to do it live – with coaching

Technical Report Writing and Presentation Skills In the AI Era – For Engineers, Scientists and Technical Professionals in The Energy Industry

By EnergyEdge - Training for a Sustainable Energy Future

Develop your technical report writing and presentation skills with EnergyEdge's course designed for oil & gas professionals. Sign up now!

Technical Report Writing and Presentation Skills In the AI Era – For Engineers, Scientists and Technical Professionals in The Energy Industry

By EnergyEdge - Training for a Sustainable Energy Future

Develop your technical report writing and presentation skills with EnergyEdge's course designed for oil & gas professionals. Sign up now!

CO2 Transportation From Capture to Storage and Usage

By EnergyEdge - Training for a Sustainable Energy Future

Join EnergyEdge's course on CO2 transportation from capture to storage and usage. Gain valuable knowledge in classroom training sessions.

Introduction to Data Analytics & Visualization

By EnergyEdge - Training for a Sustainable Energy Future

Develop your expertise in data analytics and visualization with EnergyEdge's Introduction to Data Analytics Visualization course. Join our classroom training to acquire essential skills in this field.

NVQ Level 2 Diploma in Construction Operations and Civil Engineering Services - Roadbuilding

5.0(29)By Site Competence

Blue CSCS Card Level 2 NVQ Diploma in Construction Operations and Civil Engineering Services - Roadbuilding This qualification provides you with the opportunity to showcase their knowledge, skills and understanding in their chosen within the Civil Engineering and Highways Sector. You will have the relevant experience at least one of the 14 specific specialisms. You will work in one of the following areas: Pathway 1: Bituminous Paving - Machine Pathway 2: Concrete Paving - Machine Pathway 3: Slurry/Micro Surfacing - Machine Pathway 4: Slurry/Micro Surfacing - Manual Pathway 5: Surface Dressing - Machine Pathway 6: High Friction Surfacing - Machine Pathway 7: High Friction Surfacing - Manual Pathway 8: Planing - Machine Pathway 9: Road Recycling - Machine Pathway 10: Soil Stabilisation - Machine Pathway 11: Surface Retexturing - Machine Pathway 12: Pavement Marking - Machine Pathway 13 Pavement Marking - Manual operations Pathway 14: Pavement Marking - Road Studs Induction - As soon as you register you will be given a dedicated assessor. They will arrange an induction and together with your assessor, you will get to decide on the pathway which best proves your competency. The induction is used to plan out how you will gather the relevant evidence to complete the course. During the course - The assessor will work with you to build a portfolio of evidence that allows you to showcase your knowledge, skills and experience. The assessor will also regularly review and provide you with feedback. This will allow you to keep on track to progress quickly. You will be assessed through various methods such as observations, written questions, evidence generated from the workplace, professional discussion, and witness testimonials. On completion - Once all feedback has been agreed, the Internal Quality Assurer will review your portfolio and in agreement with your assessor the certificate will be applied for. To download our PDF for this course then please click here.

Flow Assurance for Offshore Production

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your knowledge with EnergyEdge's course on flow assurance for offshore production. Join our classroom training to gain valuable insights.

Industrial Instrumentation and Modern Control Systems

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 5 full-day course provide a comprehensive understanding of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, HART protocol, control valves, actuators, and smart technology. This course will focus on maximizing the efficiency, reliability, and longevity of these systems and equipment by providing an understanding of the characteristics, selection criteria, common problems and repair techniques, preventive and predictive maintenance. This course is a MUST for anyone who is involved in the selection, applications, or maintenance of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology because it covers how these systems and equipment operate, the latest maintenance techniques, and provides guidelines and rules that ensure their successful operation. In addition, this course will cover in detail the basic design, operating characteristics, specification, selection criteria, advanced fault detection techniques, critical components and all preventive and predictive maintenance methods in order to increase the reliability of these systems andequipment and reduce their operation and maintenance cost This course will provide the following information for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology: Basic Design Specification Selection Criteria Sizing Calculations Enclosures and Sealing Arrangements Codes and Standards Common Operational Problems All Diagnostics, Troubleshooting, Testing, and Maintenance Practical applications of smart instrumentation, SCADA, and Distributed Control Systems, control valves, actuators, etc in the following industries will be discussed in detail: Chemical and petrochemical Power generation Pulp and paper Aerospace Water and sewage treatment Electrical power grids Environmental monitoring and control systems Pharmaceutical plants Training Objectives Equipment Operation: Gain a thorough understanding of the operating characteristics of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Diagnostics and Inspection: Learn in detail all the diagnostic techniques and inspections required of critical components of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Testing: Understand thoroughly all the tests required for the various types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Maintenance and Troubleshooting: Determine all the maintenance and troubleshooting activities required to minimize the downtime and operating cost of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Repair and Refurbishment: Gain a detailed understanding of the various methods used to repair and refurbish modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Efficiency, Reliability, and Longevity: Learn the various methods used to maximize the efficiency, reliability, and longevity of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Sizing: Gain a detailed understanding of all the calculations and sizing techniques used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Design Features: Understand all the design features that improve the efficiency and reliability of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Selection: Learn how to select modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology by using the performance characteristics and selection criteria that you will learn in this course Equipment Enclosures and Sealing Methods Learn about the various types of enclosures and sealing arrangements used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Commissioning: Understand all the commissioning requirements for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Codes and Standards: Learn all the codes and standards applicable for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Causes and Modes of Failure: Understand the causes and modes of failure of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology System Design: Learn all the requirements for designing different types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: Industrial Instrumentation and Modern Control Systems Practical Manual (400 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Search By Location

- Experience Courses in London

- Experience Courses in Birmingham

- Experience Courses in Glasgow

- Experience Courses in Liverpool

- Experience Courses in Bristol

- Experience Courses in Manchester

- Experience Courses in Sheffield

- Experience Courses in Leeds

- Experience Courses in Edinburgh

- Experience Courses in Leicester

- Experience Courses in Coventry

- Experience Courses in Bradford

- Experience Courses in Cardiff

- Experience Courses in Belfast

- Experience Courses in Nottingham