- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

67 Crane courses

NOCN NVQ Level 2 Diploma in Hire and Rental Operations

By Learning for Hire Limited

NOCN NVQ Level 2 Diploma in Hire and Rental Operations

Level 2 NVQ Certificate in Plant Operations - Attachments

By Dynamic Training and Assessments Ltd

Level 2 NVQ Certificate in Plant Operations - Attachments

Level 2 NVQ Certificate in Plant Operations - Road / Rail

By Dynamic Training and Assessments Ltd

Level 2 NVQ Certificate in Plant Operations - Road / Rail

Expert in General Cargo Inspection/ Cargo Survey

By International Maritime Training

In today's dynamic global trade landscape, expertise in cargo inspection is more valuable than ever. Our comprehensive program is designed to equip you with the knowledge, skills, and certification needed to excel in the field of general cargo inspection, this comprehensive program is designed to empower maritime professionals like you with the skills and knowledge needed to excel in the ever-evolving maritime landscape. General cargo, in the context of shipping, refers to a broad category of goods that are typically non-specialized and not classified as bulk cargo or containerized cargo. These are goods that are individually packaged, bundled, or palletized and are not loaded into dedicated containers. General cargo can include a wide variety of items, ranging from machinery, equipment, and vehicles to consumer goods, textiles, and packaged products. Ships transporting general cargo are equipped with versatile cargo-handling facilities such as cranes and derricks to load and unload these diverse goods. General cargo vessels are adaptable and capable of carrying different types of merchandise, making them suitable for various industries and trade routes. The flexibility in handling different types of goods makes general cargo shipping an essential component of global trade. Elevate your career in cargo inspection with our Advanced Diploma in General Cargo Inspection! Enroll now and gain in-depth knowledge in: CS001: Marine Cargo Survey Practices CS002: Essential Law for Cargo Surveyors CS003: Technical Report Writing Skills for Surveyors CS013E: Expert in General Cargo Inspection Why Choose Our Program : Expert-Led Training: Learn from industry professionals with years of experience in cargo inspection. Flexible Learning Options: Access training materials online at your own pace, from anywhere in the world. Practical Insights: Gain real-world insights and case studies to enhance your understanding of cargo inspection challenges and solutions. Certification: Upon successful completion of the program, receive a recognized advanced diploma as an Expert in General Cargo Inspection. Take the Next Step : Ready to elevate your cargo inspection expertise? Enroll now and join our community of skilled professionals dedicated to excellence in cargo inspection. 🌐 Why Choose Us ? Our commitment to excellence, coupled with a history of successful alumni, makes us the perfect choice for your maritime education. Enroll today and set sail towards a brighter future in the maritime world!

Level 4 NVQ Diploma in Controlling Lifting Operations - Supervising Lifts

By Dynamic Training and Assessments Ltd

Level 4 NVQ Diploma in Controlling Lifting Operations - Supervising Lifts

Lorry Loader Training The aim of the Lorry Loader Training or Clamshell Bucket Courses is to provide the candidate with the basic knowledge and practical skills involved in operating a Lorry Loader ( HIAB ) or clamshell bucket courses, and on successful completion of the practical test, you will be issued with the NPORS Identity card with or without the CSCS logo. Discounts are available for multiple bookings NPORS/CSCS Lorry loader Experienced Worker Test or Training can only be delivered on our customer’s sites nationwide, Therefore reducing downtime and disruption of works to our clients. Experienced operator – NPORS Lorry Loader Test Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Lorry Loader Experienced Test Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Lorry Loader Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Click for our terms and conditions Your skills, our commitment—always at the best price. NPORS Lorry Loader Test is for operators who have received some form of training in the past or alternatively has been operating the Lorry Loader for several years. If you are unsure if you qualify to go down the test route please contact us to discuss this in more detail. Discounts are available for multiple bookings There are two parts to the lorry loader test, a theory section comprised of 25 questions and a practical session. Lorry Loader Training Course: Safely Operating Mobile Crane Vehicles 1. Introduction to Lorry Loaders Overview of lorry loader types and configurations Understanding the components and controls of a lorry loader Different applications and lifting capacities of lorry loaders 2. Lorry Loader Safety Procedures Importance of safety in lorry loader operation Pre-operational checks and inspections Understanding load charts and load capacities Personal protective equipment (PPE) requirements Emergency procedures: shutdown, lockout/tagout, and evacuation protocols 3. Lorry Loader Operation Basics Starting, stopping, and controlling the lorry loader, include emergency stops Familiarisation with lorry loader controls: boom, remote, and outriggers Manoeuvring the lorry loader on different terrain types: roads, construction sites, etc. Lifting and lowering loads safely and accurately 4. Load Handling Techniques Proper assessment of loads: weight, size, and stability Positioning the lorry loader for efficient loading and unloading Securing loads with proper rigging techniques: slings, chains, and hooks Stacking and de-stacking loads safely and efficiently Using other professionals to complete the work. Slinger signaller to direct the load 5. Site Safety and Hazard Awareness Identifying potential hazards in the workplace Working safely around pedestrians, other vehicles, and obstacles Recognising environmental hazards: overhead obstructions, power lines, etc. Understanding site-specific safety rules and regulations 6. Maintenance and Inspections Importance of regular maintenance for lorry loader performance and reliability Daily, pre-shift, and post-shift inspection procedures Lubrication points and maintenance schedules Identifying and reporting mechanical issues and wear parts replacement 7. Practical Hands-On Training Practical exercises in lorry loader operation under supervision Manoeuvring through obstacle courses and confined spaces Load handling exercises: lifting, positioning, and placing loads Emergency response drills: simulated scenarios to test response and decision-making skills 8. Assessment and Certification Written examination to assess theoretical knowledge Practical assessment of lorry loader operation skills Certification upon successful completion of the course A lorry loader training course, by Vally Plant Training provides participants with the essential knowledge, skills, and confidence to operate lorry loaders safely and efficiently in various work environments. By covering topics such as safety procedures, operation techniques, load handling, site awareness, maintenance practices, and practical hands-on training, participants can enhance their proficiency and contribute to a safer and more productive workplace. Whether you’re a novice operator or an experienced professional, investing in lorry loader training is essential for ensuring compliance, reducing risks, and maximising productivity in lifting operations. Lorry Loader Training Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who have a wealth of knowledge of lorry loader and the construction industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built HIAB practical training area to simulate an actual working environment. Our Lorry Loader or clamshell bucket courses and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS LORRY LOADER Tester to your site nationwide, to reduce the amount of time away from work More courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today. Frequently Asked Questions 1. What is the aim of the Lorry Loader Training course? • The course aims to provide candidates with the basic knowledge and practical skills involved in operating a Lorry Loader (HIAB) or clamshell bucket. Successful completion of the practical test will result in receiving the NPORS Identity card with or without the CSCS logo. 2. What does the Lorry Loader training course cover? • The course covers various aspects, including: o Types and configurations of lorry loaders o Safety procedures and pre-operational checks o Operation basics, including controls and manoeuvring o Load handling techniques o Site safety and hazard awareness o Maintenance and inspection procedures o Practical hands-on training and assessments 3. What is the duration of the Lorry Loader Training course? • For experienced operators, the course is a 1-day test, accommodating up to 4 candidates. For novice operators, it is a 2-day training session, accommodating up to 3 candidates. 4. Where is the training conducted? • Training can be conducted at the client’s site nationwide, which helps reduce downtime and disruption to work. The training centre is located near the M5 junction 9 in Tewkesbury, with a purpose-built HIAB practical training area. 5. What are the certification options available? • There are two certification options: o NPORS traditional card (valid for 5 years) o NPORS card with CSCS logo (initial RED trained operator card valid for 2 years, upgradable to BLUE competent operator card upon completing relevant NVQ) For those looking for a “NPORS Lorry Loader Training near me,” our widespread operations make it convenient for you to access Vally Plant Trainings top-quality training no matter where you are in the UK

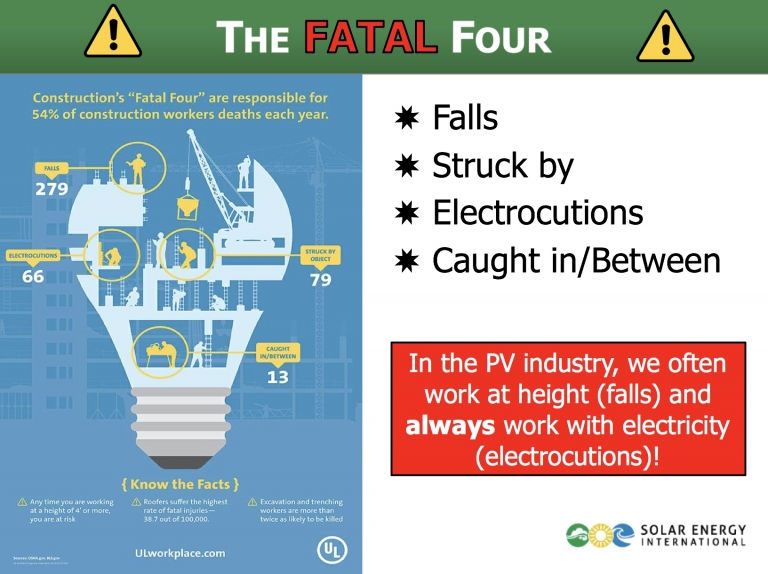

CE523: Residential/Commercial Roof-Mounted PV Installation Safety

By Solar Energy International (SEI)

This training includes four (4) three-hour lessons, for a total of 12 contact training hours. Each lesson will include presentations, videos, interactive exercises, and a quiz. 1- Ladder and Lift Safety: In this lesson, we learn about different ladder options and how to choose the appropriate ladder(s) for a PV installation, based on the specific job site and task (accessing different roof surfaces, running conduit, etc.). We discuss how to properly inspect, set up and use ladders, and through interactive exercises we evaluate different installation sites to determine the best location to set up an extension ladder to access the PV array. In the second part of this lesson, we identify equipment and methods for safely lifting PV modules (and other materials) to the roof, including ladder lifts, boom lifts, reach forklifts, scaffolding, and cranes. 2- Fall Protection: Here, we review OSHA fall protection requirements and present different equipment options for working safely AND efficiently on a PV job site. We discuss the differences between fall restraint, positioning, and fall arrest systems; look at different anchor options for roof surfaces commonly seen on PV installations; and via interactive exercises determine where to place those anchors on the roof. 3- PV Mounting Safety: In this lesson, we identify job site hazards specific to PV mounting work, from array layout through securing modules to the racking system. We go step-by-step through a roof-mounted PV installation and call out ways to eliminate and/or control hazards through safe work practices, engineering controls, and personal protective equipment (PPE). Through interactive exercises and videos, we show best practice methods to safely handle PV equipment and manage small parts on a sloped roof. 4- Solar Electric Safety: In the final lesson of this series, we take an in-depth look at electrical hazards specific to PV installation and maintenance work, and discuss the requirements of OSHA, the NEC, and NFPA 70E to assure safe working conditions. We discuss shock and arc flash hazards and identify protective measures (including PPE and lockout / tagout). We dive even further into lockout / tagout and safe electrical testing methods in our interactive exercises and videos.

NPORS Industrial Telescopic Handler (N010A)

By Dynamic Training and Assessments Ltd

NPORS Industrial Telescopic Handler (N010A)

NPORS Industrial Counterbalance Lift Truck (N001)

By Dynamic Training and Assessments Ltd

NPORS Industrial Counterbalance Lift Truck (N001)

LOLER Inspection Training

By Compliance Central

LOLER 1998 regulations apply to any organisation that uses lifting equipment, prioritising health and safety. This LOLER Inspection Training course focuses on safety measures when working with lifting equipment. As per the LOLER Approved Code and Practice and Guidance, comprehensive inspections of lifting equipment require practical and theoretical understanding of the said equipment. The course equips both employers and employees with this understanding, clarifying LOLER expectations and helping reduce risk associated with lifting equipment. Learning Outcomes of the LOLER course Specify the lifting equipment and supplies. Learn about LOLER and the regulations surrounding health and safety. Establish a plan and supervise the lifting operation. Determine the elements that affect safe lifting operations. Understand the duties of the LOLER manager Examine the issues and report them accordingly Why would you choose the LOLER Inspection course: Lifetime access to LOLER Inspection course materials Full tutor support is available from Monday to Friday with the LOLER Inspection course Learn LOLER Inspection skills at your own pace from the comfort of your home Gain a complete understanding of LOLER Inspection course Accessible, informative LOLER Inspection learning modules designed by experts Get 24/7 help or advice from our email and live chat teams with the Study LOLER Inspection in your own time through your computer, tablet or mobile device A 100% learning satisfaction guarantee with your LOLER Inspection course LOLER Inspection Curriculum Breakdown of the LOLER Inspection Course Module 01: Introduction to LOLER Module 02: Part 01 - Selecting Lifting Equipment and Accessories Module 03: Part 02 - Selecting Lifting Equipment and Accessories Module 04: Planning the Lifting Operation Module 05: Factors Affecting Safe Lifting Operation Module 06: Roles and Responsibilities Module 07: Risk Assessment Module 08: Examination and Inspection Module 09: Reports and Defects CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? This LOLER Inspection Training is open to all, and it is perfect for introduction and refresher training for staff members who have little to no experience with health and safety procedures and LOLER. Also, People who are genuinely interested in construction engineering will enjoy learning People working with lifting and operating equipment and who want to brush up their knowledge Requirements To enrol in this LOLER Inspection course, all you need is a basic understanding of the English Language and an internet connection. Career path The LOLER Inspection course will enhance your knowledge and improve your confidence in exploring opportunities in various sectors related to. Field Service Engineer (Salary: £28,000 - £30,000 per annum) Building Surveyor (Salary: £25,000 to £70,000 per year) Cranes Engineer Surveyor (Salary: Upto £42,750 per annum) Certificates Certificate of completion Digital certificate - Included Get a CPD accredited PDF certificate for Free. Certificate of completion Hard copy certificate - Included Get a CPD accredited Hardcopy certificate for Free. After successfully completing this LOLER Inspection Training course, you get a PDF and a hardcopy certificate for free. The delivery charge of the hardcopy certificate inside the UK is £3.99 and international students need to pay £9.99 to get their hardcopy certificate.

Search By Location

- Crane Courses in London

- Crane Courses in Birmingham

- Crane Courses in Glasgow

- Crane Courses in Liverpool

- Crane Courses in Bristol

- Crane Courses in Manchester

- Crane Courses in Sheffield

- Crane Courses in Leeds

- Crane Courses in Edinburgh

- Crane Courses in Leicester

- Crane Courses in Coventry

- Crane Courses in Bradford

- Crane Courses in Cardiff

- Crane Courses in Belfast

- Crane Courses in Nottingham