- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

343 Computing & IT courses in Birmingham

MEAN Stack courses in Dubai

By Edoxi Training Institute

Edoxi's MEAN Stack Course in Dubai equips you with essential skills to become a proficient developer. Edoxi's MEAN Stack course helps you build, deploy, and maintain full-stack JavaScript applications using the MEAN Stack framework. Our MEAN Stack course features one-on-one mentorship from our experts. Discover practical learning and implement your MEAN Stack skills in real-world situations through our project-centric approach, which emphasizes the importance of hands-on experience. Enroll in Our MEAN Stack Course and Gain Hands-On Experience with Expert Mentorship! Call us: +971 4380 1666 Mail us, at info@edoxi.com Learn more:https://www.edoxi.com/dubai/mean-stack-course Address: Office 504, Bank Street Building, Next to Burjuman Metro Station Exit 3, Khalid Bin Al Waleed Rd, Dubai, United Arab Emirates

Cara Memicu Fitur Bonus di Slot Golden Dragon

By MehtapNaranjargal

Slot Golden Dragon menawarkan pengalaman bermain yang mendebarkan dengan berbagai fitur bonus yang dapat meningkatkan peluang pemain untuk menang. Memahami cara memicu fitur-fitur ini adalah kunci untuk memaksimalkan pengalaman bermain Anda. Dalam artikel ini, kita akan membahas cara-cara untuk memicu fitur bonus di Slot Golden Dragon, termasuk simbol-simbol penting, strategi bermain, dan tips tambahan. Memahami Simbol Fitur Bonus Salah satu aspek terpenting dalam memicu fitur bonus di Slot Golden Dragon adalah mengenali simbol-simbol yang berfungsi sebagai pemicu. Setiap slot biasanya memiliki simbol khusus yang dapat membuka berbagai bonus ketika muncul dalam jumlah tertentu. Di Golden Dragon, simbol liar dan simbol pencar (scatter) adalah yang paling umum memberikan akses ke fitur bonus. Simbol liar biasanya menggantikan simbol lain untuk membentuk kombinasi yang menang. Di sisi lain, simbol pencar sering kali memicu putaran bonus atau free spins ketika Anda mendapatkan sejumlah tertentu di layar. Pastikan untuk mencermati tabel pembayaran untuk mengetahui simbol-simbol ini dan bagaimana cara kerjanya. Slot Golden Dragon adalah salah satu permainan yang paling menarik dan menghibur di dunia kasino dewa togel online. Dengan desain yang memesona dan berbagai fitur menarik, permainan ini menawarkan pengalaman bermain yang mengasyikkan. Dalam panduan ini, kita akan menjelajahi berbagai aspek yang perlu Anda ketahui untuk bermain di Slot Golden Dragon, mulai dari pengenalan permainan hingga strategi untuk meningkatkan peluang menang. Selain itu, beberapa slot juga memiliki simbol bonus khusus yang hanya muncul di kondisi tertentu. Misalnya, Anda mungkin perlu mendapatkan tiga atau lebih simbol bonus pada gulungan untuk mengaktifkan fitur bonus tertentu. Memahami cara kerja simbol-simbol ini akan memberi Anda keunggulan dalam permainan dan membantu Anda merencanakan strategi yang lebih baik. Meningkatkan Peluang Memicu Fitur Bonus Setelah memahami simbol-simbol penting, langkah selanjutnya adalah meningkatkan peluang Anda untuk memicu fitur bonus. Salah satu cara untuk melakukannya adalah dengan memilih ukuran taruhan yang tepat. Dalam banyak permainan slot, semakin tinggi taruhan Anda, semakin besar peluang Anda untuk memicu fitur bonus. Namun, penting untuk mempertimbangkan anggaran Anda dan bermain secara bertanggung jawab. Selain itu, cobalah bermain di mode asialive88 sebelum bermain dengan uang sungguhan. Dengan cara ini, Anda dapat menguji berbagai strategi dan melihat bagaimana fitur bonus dipicu dalam permainan. Ini juga memberi Anda gambaran yang lebih baik tentang kapan dan bagaimana Anda dapat mengharapkan fitur bonus muncul. Banyak kasino memberikan bonus deposit atau putaran gratis yang dapat Anda gunakan untuk meningkatkan peluang memicu fitur bonus. Ketika Anda menggunakan bonus ini, Anda dapat bermain lebih lama dan memiliki lebih banyak kesempatan untuk mendapatkan kombinasi yang menguntungkan dan memicu fitur bonus. Sebelum memulai permainan, penting untuk memahami apa itu Slot Golden Dragon. Permainan ini mengusung tema budaya Asia, khususnya yang berkaitan dengan simbol-simbol naga yang melambangkan keberuntungan dan kekuatan. Desain grafis yang cerah dan animasi yang halus memberikan pengalaman visual yang menyenangkan. Pemain akan menemukan berbagai simbol yang memiliki makna khusus, seperti koin emas, lentera, dan simbol liar yang dapat menggantikan simbol lain untuk membentuk kombinasi yang menang. Strategi Bermain untuk Memicu Fitur Bonus Mengembangkan strategi bermain yang efektif juga sangat penting dalam memicu fitur bonus bola88 online di Slot Golden Dragon. Salah satu pendekatan adalah bermain secara konsisten dan berfokus pada pengelolaan bankroll. Tentukan batasan harian atau mingguan untuk diri Anda sendiri dan patuhi itu. Selain itu, cobalah untuk beradaptasi dengan pola permainan. Amati ketika fitur bonus sering kali dipicu dan perhatikan apakah ada pola tertentu yang dapat Anda manfaatkan. Beberapa pemain percaya bahwa fitur bonus cenderung muncul setelah beberapa putaran tanpa kemenangan. Meskipun ini tidak selalu benar, mengamati pola dapat memberi Anda wawasan tentang kapan waktu terbaik untuk meningkatkan taruhan Anda. Terakhir, jangan ragu untuk mencoba berbagai variasi permainan. Setiap versi Slot Golden Dragon mungkin memiliki cara berbeda dalam memicu fitur bonus. Dengan mencoba berbagai variasi, Anda dapat menemukan mana yang paling sesuai dengan gaya bermain Anda dan mana yang memberikan peluang terbaik untuk memicu bonus. Variasi ini bisa menjadi kunci untuk menemukan cara yang paling efektif dalam meraih kemenangan. Tips Tambahan untuk Memicu Fitur Bonus Selain strategi dan pemahaman dasar tentang simbol, ada beberapa tips tambahan yang dapat membantu Anda memicu fitur bonus di Slot Golden Dragon. Pertama, selalu periksa tabel pembayaran sebelum mulai bermain. Tabel pembayaran memberikan informasi penting tentang simbol-simbol, kombinasi yang menang, dan cara memicu fitur bonus. Memahami ini akan membantu Anda merencanakan langkah selanjutnya dengan lebih baik. Kedua, jangan terburu-buru saat bermain. Banyak pemain merasa tertekan untuk segera mendapatkan kemenangan, tetapi permainan slot togel online adalah tentang kesabaran. Luangkan waktu untuk menikmati permainan dan jangan ragu untuk berhenti sejenak jika Anda merasa frustrasi. Ketenangan pikiran dapat membantu Anda mengambil keputusan yang lebih baik dan meningkatkan peluang Anda untuk memicu fitur bonus. Akhirnya, bergabunglah dengan komunitas pemain slot online. Dengan mendengarkan pengalaman orang lain, Anda dapat memperoleh tips berharga mengenai cara terbaik untuk memicu fitur bonus di Slot Golden Dragon. Komunitas ini juga bisa menjadi tempat untuk mendiskusikan permainan dan mendapatkan informasi terbaru tentang event atau promosi yang dapat Anda manfaatkan. Kesimpulan Memicu fitur bonus di Slot Golden Dragon membutuhkan pemahaman yang baik tentang simbol, strategi bermain yang efektif, dan kesabaran. Dengan mengikuti panduan ini, Anda akan meningkatkan peluang Anda untuk meraih kemenangan dan menikmati pengalaman bermain yang lebih menyenangkan. Ingatlah untuk bermain secara bertanggung jawab dan selalu bersenang-senang saat bermain.

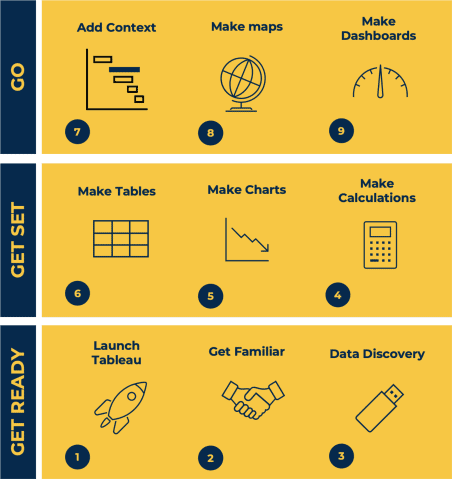

Tableau Desktop Training - Foundation

By Tableau Training Uk

This Tableau Desktop Training course is a jumpstart to getting report writers and analysts with little or no previous knowledge to being productive. It covers everything from connecting to data, through to creating interactive dashboards with a range of visualisations in two days of your time. For Private options, online or in-person, please send us details of your requirements: This Tableau Desktop Training course is a jumpstart to getting report writers and analysts with little or no previous knowledge to being productive. It covers everything from connecting to data, through to creating interactive dashboards with a range of visualisations in two days of your time. Having a quick turnaround from starting to use Tableau, to getting real, actionable insights means that you get a swift return on your investment of time and money. This accelerated approach is key to getting engagement from within your organisation so everyone can immediately see and feel the impact of the data and insights you create. This course is aimed at someone who has not used Tableau in earnest and may be in a functional role, eg. in sales, marketing, finance, operations, business intelligence etc. The course is split into 3 phases and 9 modules: PHASE 1: GET READY MODULE 1: LAUNCH TABLEAU Check Install & Setup Why is Visual Analytics Important MODULE 2: GET FAMILIAR What is possible How does Tableau deal with data Know your way around How do we format charts Dashboard Basics – My First Dashboard MODULE 3: DATA DISCOVERY Connecting to and setting up data in Tableau How Do I Explore my Data – Filters & Sorting How Do I Structure my Data – Groups & Hierarchies, Visual Groups How Tableau Deals with Dates – Using Discrete and Continuous Dates, Custom Dates Phase 2: GET SET MODULE 4: MAKE CALCULATIONS How Do I Create Calculated Fields & Why MODULE 5: MAKE CHARTS Charts that Compare Multiple Measures – Measure Names and Measure Values, Shared Axis Charts, Dual Axis Charts, Scatter Plots Showing Relational & Proportional Data – Pie Charts, Donut Charts, Tree Maps MODULE 6: MAKE TABLES Creating Tables – Creating Tables, Highlight Tables, Heat Maps Phase 3: GO MODULE 7: ADD CONTEXT Reference Lines and Bands MODULE 8: MAKE MAPS Answering Spatial Questions – Mapping, Creating a Choropleth (Filled) Map MODULE 9: MAKE DASHBOARDS Using the Dashboard Interface Dashboard Actions This training course includes over 25 hands-on exercises and quizzes to help participants “learn by doing” and to assist group discussions around real-life use cases. Each attendee receives a login to our extensive training portal which covers the theory, practical applications and use cases, exercises, solutions and quizzes in both written and video format. Students must use their own laptop with an active version of Tableau Desktop 2018.2 (or later) pre-installed. What People Are Saying About This Course “Excellent Trainer – knows his stuff, has done it all in the real world, not just the class room.”Richard L., Intelliflo “Tableau is a complicated and powerful tool. After taking this course, I am confident in what I can do, and how it can help improve my work.”Trevor B., Morrison Utility Services “I would highly recommend this course for Tableau beginners, really easy to follow and keep up with as you are hands on during the course. Trainer really helpful too.”Chelsey H., QVC “He is a natural trainer, patient and very good at explaining in simple terms. He has an excellent knowledge base of the system and an obvious enthusiasm for Tableau, data analysis and the best way to convey results. We had been having difficulties in the business in building financial reports from a data cube and he had solutions for these which have proved to be very useful.”Matthew H., ISS Group

Visual Analytics Best Practice

By Tableau Training Uk

This course is very much a discussion, so be prepared to present and critically analyse your own and class mates work. You will also need to bring a few examples of work you have done in the past. Learning and applying best practice visualisation principles will improve effective discussions amongst decision makers throughout your organisation. As a result more end-users of your dashboards will be able to make better decisions, more quickly. This 2 Day training course is aimed at analysts with good working knowledge of BI tools (we use Tableau to present, but attendees can use their own software such as Power BI or Qlik Sense). It is a great preparation for taking advanced certifications, such as Tableau Certified Professional. Contact us to discuss the Visual Analytics Best Practice course Email us if you are interested in an on-site course, or would be interested in different dates and locations This Tableau Desktop training intermediate course is designed for the professional who has a solid foundation with Tableau and is looking to take it to the next level. Attendees should have a good understanding of the fundamental concepts of building Tableau worksheets and dashboards typically achieved from having attended our Tableau Desktop Foundation Course. At the end of this course you will be able to communicate insights more effectively, enabling your organisation to make better decisions, quickly. The Tableau Desktop Analyst training course is aimed at people who are used to working with MS Excel or other Business Intelligence tools and who have preferably been using Tableau already for basic reporting. The course includes the following topics: WHAT IS VISUAL ANALYSIS? Visual Analytics Visual Analytics Process Advantages of Visual Analysis Exercise: Interpreting Visualisations HOW DO WE PROCESS VISUAL INFORMATION? Memory and Processing Types Exercise: Identifying Types of Processing Cognitive Load Exercise: Analysing Cognitive Load Focus and Guide the Viewer Remove Visual Distractions Organise Information into Chunks Design for Proximity Exercise: Reducing Cognitive Load SENSORY MEMORY Pre-attentive Attributes Quantitatively-Perceived Attributes Categorically-Perceived Attributes Exercise: Analysing Pre-attentive Attributes Form & Attributes Exercise: Using Form Effectively Colour & Attributes Exercise: Using Colour Effectively Position & Attributes Exercise: Using Position Effectively ENSURING VISUAL INTEGRITY Informing without Misleading Gestalt Principles Visual Area Axis & Scale Colour Detail Exercise: Informing without Misleading CHOOSING THE RIGHT VISUALISATION Comparing and Ranking Categories Comparing Measures Comparing Parts to Whole Viewing Data Over Time Charts Types for Mapping Viewing Correlation Viewing Distributions Viewing Specific Values DASHBOARDS AND STORIES Exercise: Picking the Chart Type Exercise: Brainstorming Visual Best Practice Development Process for Dashboards and Stories Plan the Visualisation Create the Visualisation Test the Visualisation Exercise: Designing Dashboards and Stories This training course includes over 20 hands-on exercises to help participants “learn by doing” and to assist group discussions around real-life use cases. Each attendee receives an extensive training manual which covers the theory, practical applications and use cases, exercises and solutions together with a USB with all the materials required for the training. The course starts at 09:30 on the first day and ends at 17:00. On the second day the course starts at 09:00 and ends at 17:00. Students must bring their own laptop with an active version of Tableau Desktop 10.5 (or later) pre-installed. What People Are Saying About This Course "Steve was willing to address questions arising from his content in a full and understandable way"Lisa L. "Really enjoyed the course and feel the subject and the way it was taught was very close to my needs"James G. "The course tutor Steve was incredibly helpful and taught the information very well while making the two days very enjoyable."Bradd P. "The host and his courses will give you the tools and confidence that you need to be comfortable with Tableau."Jack S. "Steve was fantastic with his knowledge and knowhow about the product. Where possible he made sure you could put demonstrations in to working practice, to give the audience a clear understanding."Tim H. "This was a very interesting and helpful course, which will definitely help me produce smarter, cleaner visualisations that will deliver more data-driven insights within our business."Richard A. "Steve is very open to questions and will go out of his way to answer any query. Thank you"Wasif N. "Steve was willing to address questions arising from his content in a full and understandable way"Lisa L. "Really enjoyed the course and feel the subject and the way it was taught was very close to my needs"James G.

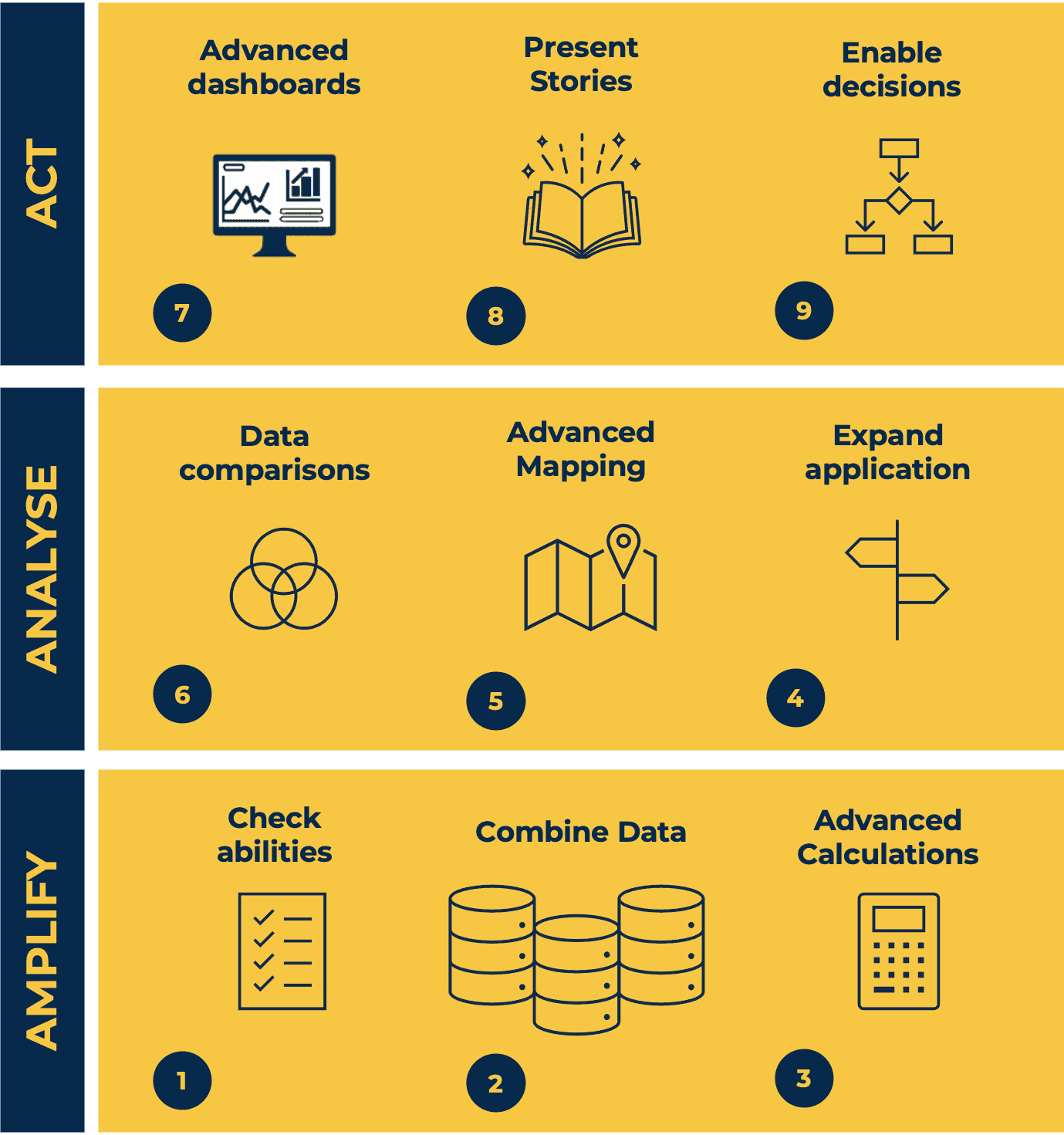

Tableau Desktop Training - Analyst

By Tableau Training Uk

This Tableau Desktop Training intermediate course is designed for the professional who has a solid foundation with Tableau and is looking to take it to the next level. For Private options, online or in-person, please send us details of your requirements: This Tableau Desktop training intermediate course is designed for the professional who has a solid foundation with Tableau and is looking to take it to the next level. Attendees should have a good understanding of the fundamental concepts of building Tableau worksheets and dashboards typically achieved from having attended our Tableau Desktop Foundation Course. At the end of this course you will be able to communicate insights more effectively, enabling your organisation to make better decisions, quickly. The Tableau Desktop Analyst training course is aimed at people who are used to working with MS Excel or other Business Intelligence tools and who have preferably been using Tableau already for basic reporting. The course is split into 3 phases and 9 modules: Phase 1: AMPLIFY MODULE 1: CHECK ABILITIES Revision – What I Should Know What is possibleHow does Tableau deal with dataKnow your way aroundHow do we format chartsHow Tableau deals with datesCharts that compare multiple measuresCreating Tables MODULE 2: COMBINE DATA Relationships Joining Tables – Join Types, Joining tables within the same database, cross database joins, join calculations Blending – How to create a blend with common fields, Custom defined Field relationships and mismatched element names, Calculated fields in blended data sources Unions – Manual Unions and mismatched columns, Wildcard unions Data Extracts – Creating & Editing Data extracts MODULE 3: ADVANCED CALCULATIONS Row Level v Aggregations Aggregating dimensions in calculations Changing the Level of Detail (LOD) of calculations – What, Why, How Adding Table Calculations Phase 2: ANALYSE MODULE 4: EXPAND APPLICATION Making things dynamic with parameters Sets Trend Lines How do we format charts Forecasting MODULE 5: ADVANCED MAPPING Using your own images for spatial analysis Mapping with Spatial files MODULE 6: DATA COMPARISONS Advanced Charts Bar in Bar charts Bullet graphs Creating Bins and Histograms Creating a Box & Whisker plot Phase 3: ACT MODULE 7: ADVANCED DASHBOARDS Using the dashboard interface and Device layout Dashboard Actions and Viz In tooltips Horizontal & Vertical containers Navigate between dashboards MODULE 8: PRESENT STORIES Telling data driven stories MODULE 9: ENABLE DECISIONS What is Tableau Server Publishing & Permissions How can your users engage with content This training course includes over 25 hands-on exercises and quizzes to help participants “learn by doing” and to assist group discussions around real-life use cases. Each attendee receives a login to our extensive training portal which covers the theory, practical applications and use cases, exercises, solutions and quizzes in both written and video format. Students must bring their own laptop with an active version of Tableau Desktop 2018.2 (or later) pre-installed. What People Are Saying About This Course “Course was fantastic, and completely relevant to the work I am doing with Tableau. I particularly liked Steve’s method of teaching and how he applied the course material to ‘real-life’ use-cases.”Richard W., Dashboard Consulting Ltd “This course was extremely useful and excellent value. It helped me formalise my learning and I have taken a lot of useful tips away which will help me in everyday work.” Lauren M., Baillie Gifford “I would definitely recommend taking this course if you have a working knowledge of Tableau. Even the little tips Steve explains will make using Tableau a lot easier. Looking forward to putting what I’ve learned into practice.”Aron F., Grove & Dean “Steve is an excellent teacher and has a vast knowledge of Tableau. I learned a huge amount over the two days that I can immediately apply at work.”John B., Mporium “Steve not only provided a comprehensive explanation of the content of the course, but also allowed time for discussing particular business issues that participants may be facing. That was really useful as part of my learning process.”Juan C., Financial Conduct Authority “Course was fantastic, and completely relevant to the work I am doing with Tableau. I particularly liked Steve’s method of teaching and how he applied the course material to ‘real-life’ use-cases.”Richard W., Dashboard Consulting Ltd “This course was extremely useful and excellent value. It helped me formalise my learning and I have taken a lot of useful tips away which will help me in everyday work.” Lauren M., Baillie Gifford “I would definitely recommend taking this course if you have a working knowledge of Tableau. Even the little tips Steve explains will make using Tableau a lot easier. Looking forward to putting what I’ve learned into practice.”Aron F., Grove & Dean “Steve is an excellent teacher and has a vast knowledge of Tableau. I learned a huge amount over the two days that I can immediately apply at work.”John B., Mporium

10 practical ways to save time using ChatGPT and AI tools (In-House)

By The In House Training Company

ChatGPT, along with other AI tools, aims not to replace the human touch in management, but to enhance it. By addressing repetitive, daily tasks, these tools free up managers to concentrate on core responsibilities like strategic decision-making, team development, and innovation. As we move further into the digital age, integrating tools such as ChatGPT isn't a luxury; it's the future of proactive leadership. In this guide, we'll delve into 10 practical ways through which AI can elevate your efficiency and refine the quality of your work. Gain familiarity with prominent AI tools in the market Efficiently compose and respond to emails Generate concise summaries of complex reports and data. Obtain quick insights, data, and research across varied topics Streamline the writing of articles, training notes, and posts Craft interview tests, form relevant questions, and design checklists for the hiring process 1 Streamlining emails An inbox can be a goldmine of information but also a significant time drain for managers. Here's how to optimise it: Drafting responses: Give the AI a brief, and watch it craft a well-structured response. Sorting and prioritising: By employing user-defined rules and keywords, ChatGPT can flag important emails, ensuring no vital communication slips through the cracks. 2 Efficient report writing Reports, especially routine ones, can be time-intensive. Here's a smarter approach: Automate content: Supply key data points to the AI, and let it weave them into an insightful report. Proofreading: Lean on ChatGPT for grammar checks and consistency, ensuring each report remains crisp and error-free. 3 Rapid research From competitor insights to market trends, research is a pivotal part of management. Data synthesis: Feed raw data to the AI and receive succinct summaries in return. Question-answering: Pose specific questions about a dataset to ChatGPT and extract swift insights without diving deep into the entire content. 4 Reinventing recruitment Hiring can be a lengthy process. Here's how to make it more efficient: Resume screening: Equip the AI to spot keywords and qualifications, ensuring that only the most fitting candidates are shortlisted. Preliminary interviews: Leverage ChatGPT for the initial rounds of interviews by framing critical questions and evaluating the responses. 5 Enhancing training Especially for extensive teams, training can be a monumental task. Here's how ChatGPT can assist: Customised content: Inform the AI of your training goals, and it will draft tailored content suitable for various roles. PowerPoint design: Create visually appealing slide presentations on any topic in minimal time.

Python Classes in Abu Dhabi

By Time Training Center

Upskill your knowledge with Time Training Center’s Python Classes in Abu Dhabi.In this course you will master Python’s fundamental skills and web frameworks.Learn the core concepts of python such as data structures, algorithms and its implementation. Enroll now! Call us: 97126713828 Mail : info@timetraining.ae Learn more:https://www.timetraining.ae/course/python-training-course Address: Office 203, ADCP Tower - B,Behind City Seasons, Electra Street, Abu Dhabi United Arab Emirates

AWS Certification Courses In Abu Dhabi

By Time Training Center

Enhance your cloud technology knowledge with Time Training Center’s AWS Certification Courses in Abu Dhabi.Our Courses gives you hands on experience with real-world AWS solutions.By enrolling in our courses you will get to know the best practices for cloud deployment.By the end of courses you will have a comprehensive understanding of AWS and how to maximize its potential in the market today. Enroll now! Call us: 97126713828 Mail : info@timetraining.ae Learn more:https://www.timetraining.ae/course_category/aws-courses Address: Office 203, ADCP Tower - B,Behind City Seasons, Electra Street, Abu Dhabi United Arab Emirates

Cyber Security Courses In Abu Dhabi

By Time Training Center

Upgrade your cyber security skills with Time Training Center’s Cyber Security courses in Abu Dhabi. Learn how to safeguard networks and data from cyber threats. With our cyber security courses you will Learn the latest penetration testing techniques,various types of cyber threats,ways to tackle cyber threats and many more. Enroll now! Call us: 97126713828 Mail : info@timetraining.ae Learn more:https://www.timetraining.ae/course_category/cyber-security-courses-in-abu-dhabi Address: Office 203, ADCP Tower - B,Behind City Seasons, Electra Street, Abu Dhabi United Arab Emirates

Maintenance and operation (M&O) of engineering plant and services (In-House)

By The In House Training Company

M&O of engineering plant and services is becoming more important to the success of the core business. To select the right M&O technique for specific plant and equipment it is necessary to know what options are available, what they deliver and how they should be implemented. This course will help you consider options and techniques that provide best value based on that thorough understanding of the business need. M&O will increasingly be required to demonstrate it is delivering the optimum of cost and value and the main purpose of the course is to show how this can be achieved. Note: this is a purely indicative list of topics that can be covered. The content, duration, objectives and material used would all be adapted to match your specific requirements. This course will help you: Determine what the business needs from the M&O service Determine the cost and value of the various M&O options Prepare and present the business case for the selected M&O strategy Introduce meaningful KPIs based on performance-based service by the M&O provider Undertake a review of current M&O and make recommendations for improvement Introduce energy and carbon management performance criteria in M&O Better deal with project risk and uncertainties Motivate others to deliver a reliable and cost effective M&O service Note: this is a purely indicative list of topics that can be covered. The content, duration, objectives and material used would all be adapted to match your specific requirements. 1 What is maintenance and what is operation? - their relative importance to the business 2 Comparison of the various maintenance options and techniques, including: Planned preventative Run to failure Condition monitoring Business focused Business critical Total productive Reliability centred maintenance 3 Forms of contracts and service, including: Comprehensive Input driven Output driven Limited replacement Performance based M&O 4 Selecting the right options and making the business case 5 Continuous commissioning as a tool for delivering best value 6 Case studies

Search By Location

- Computing & IT Courses in London

- Computing & IT Courses in Birmingham

- Computing & IT Courses in Glasgow

- Computing & IT Courses in Liverpool

- Computing & IT Courses in Bristol

- Computing & IT Courses in Manchester

- Computing & IT Courses in Sheffield

- Computing & IT Courses in Leeds

- Computing & IT Courses in Edinburgh

- Computing & IT Courses in Leicester

- Computing & IT Courses in Coventry

- Computing & IT Courses in Bradford

- Computing & IT Courses in Cardiff

- Computing & IT Courses in Belfast

- Computing & IT Courses in Nottingham