- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

64868 Courses

Overview This course will define the scope of work, project goal, project plan, project phase, sequencing and phase relationship Project Planning & Budgeting will provide participants with a demonstrated set of methods, processes, tools and techniques to cultivate a systematic and dynamic project plan to certify progressive monitoring control and reporting of the project cost.

Overview Tendering is a process on which a lot of money relies. When a tender is issued and published, winning that contract is completely depended on how deeply you understand the tender, the key areas of the tender along with how much in-depth knowledge you have about the potential client's need and how you can provide your service to those needs.

Overview This course can offer you a transparent understanding of the credit management method and increase your confidence when handling credit management matters. This course will equip delegates with a range of enhanced communication skills to enable them to effectively collect debt by phone. These skills can be used to make sure that they are not only more effective at collecting money from customers but also maintain positive working relationships.

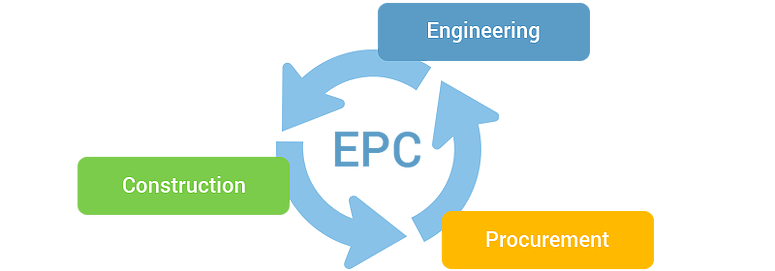

Overview EPC (Engineering, Procurement and Construction) is a very challenging area and is very competitive as well. Companies dealing with large and complex EPC projects are more often get involved in mitigation by complex contract laws and management that lead to huge financial losses. It is very important to Know-how EPC contract laws, and their commercial and financial aspects to gain skills and the ability to deal with complex contract laws and reduces the risk.

Overview Effective way of introducing automation to your project Selecting the best and right automation tool Analysing which test cases need to be automated Effective way of planning, designing and development Benefits of Automation Testing Developing scripts effectively Effectively executing and maintaining test scripts Best practices required to follow for successful automation testing Methods of using the tools to control the execution of the tests Comparing the expected outcomes with the actual outcomes Analysing regression test cases and Load testing scenarios Automating difficult tasks and repetitive tasks How to run scripts quickly and repeatedly

Overview This course will give you a whole tour of how to enhance your skills as a UI/UX Design using Adobe. It is very important to master the basics of web and visual design because that is important for UI design eg designing buttons, typography, drop shadow etc. With having a good foundation in visual and web design become an essential key to become a skilled UI/UX Designer.

Overview Intro. Translating Strategy into Goals and Metrics Components of Strategy Understanding the failure of strategies Analysing you and your organisation mission, vision and strengths Introduction into Strategy Implementation Understanding Performance Management System Objectives and Measures The importance of strategy planning

Overview We encounter lots of incidents every day at home or at work in which we need to think deeply about our decisions. Making the right choice not only saves time but also saves money and makes everyone happy. In this course, participants will learn how to refine their intuitions in order to make them trustable. Critical thinking and analysis will be a practice and habit for them and they will find themselves subconsciously using them. They will learn how to make sensible conclusions out of the data they managed to gather.

Overview The development of effective and realistic business/financial models is a critical tool in today's value-driven organization. As shareholders are increasingly concerned with the value of their investments, organizations are continually driven to ensure the optimum use of resources. Using Excel®, the Business & Financial Modelling process provides an effective tool with which the potential outcomes of various strategic and tactical initiatives can be projected. This comprehensive five-day programme takes you through the modelling process from start to finish. It provides practical examples and applications of modelling for both strategic and tactical executives.

Search By Location

- Courses in London

- Courses in Birmingham

- Courses in Glasgow

- Courses in Liverpool

- Courses in Bristol

- Courses in Manchester

- Courses in Sheffield

- Courses in Leeds

- Courses in Edinburgh

- Courses in Leicester

- Courses in Coventry

- Courses in Bradford

- Courses in Cardiff

- Courses in Belfast

- Courses in Nottingham