- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

2004 Courses

The Logistics Management and Lean Production Principles course provides a comprehensive understanding of supply chain management, logistics, and lean production techniques. Participants will explore the evolution of the supply chain, aligning it with business strategy, and implementing sustainable supply chain strategies. Additionally, they will learn about lean production principles, including the Toyota Way and the Five Principles of Lean Business. Learning Outcomes: Understand the key concepts and principles of logistics management and supply chain operations. Identify the drivers that influence supply chain performance and develop strategies to align them with business objectives. Implement risk management techniques to mitigate potential disruptions in the supply chain. Evaluate and analyze supply chain data to make informed decisions and optimize efficiency. Apply lean production principles and practices to eliminate waste and improve productivity. Utilize the Toyota Way framework to foster a culture of continuous improvement and innovation. Identify and address complexities in production processes to enhance operational efficiency. Develop an improvement toolkit to implement lean practices and enhance overall organizational performance. Certification After studying the course materials of the Logistics Management and Lean Production Principles you will be able to take the MCQ test that will assess your knowledge. After successfully passing the test you will be able to claim the pdf certificate for £5.99. Original Hard Copy certificates need to be ordered at an additional cost of £9.60. Who is this course for? Professionals working in logistics, supply chain management, or operations. Individuals interested in learning about lean production principles and their application. Business owners and managers seeking to optimize their supply chain and production processes. Anyone looking to enhance their knowledge of logistics management and lean production. Prerequisites This Logistics Management and Lean Production Principles was made by professionals and it is compatible with all PC's, Mac's, tablets and smartphones. You will be able to access the course from anywhere at any time as long as you have a good enough internet connection. Career path Logistics Manager: Oversee the entire supply chain process and optimize logistics operations. Supply Chain Analyst: Analyze data and develop strategies to improve supply chain performance. Lean Production Specialist: Implement lean principles and continuous improvement initiatives. Operations Manager: Manage production processes and optimize efficiency. Procurement Manager: Coordinate procurement activities to ensure a smooth supply chain flow. Course Curriculum Logistics Management and Lean Production Principles Logistics Manager Course Overview 00:05:00 Getting Started 00:05:00 The Evolution of the Supply Chain 00:10:00 The Basic Supply Chain Structure 00:15:00 Supply Chain Drivers 00:10:00 Aligning Your Supply Chain with Business Strategy 00:05:00 Managing Supply Chain Risks 00:05:00 Tracking and Evaluating Supply Chain Data 00:07:00 Troubleshooting Supply Chain Problems 00:05:00 Sharing Supply Chain Activities 00:05:00 Sustainable Supply Chain Strategies 00:05:00 Applying Lean Techniques to the Supply Chain 00:05:00 The Future of Supply Chain Management 00:05:00 Lean Production Module One - Getting Started 00:15:00 Module Two - Understanding Lean 00:08:00 Module Three - Liker's Toyota Way 00:08:00 Module Four - The TPS House 00:08:00 Module Five - The Five Principles of Lean Business 00:08:00 Module Six - The First Improvement Concept (Value) 00:41:00 Module Seven - The Second Improvement Concept (Waste) 00:07:00 Module Eight - The Third Improvement Concept (Variation) 00:14:00 Module Nine - The Fourth Improvement Concept (Complexity) 00:07:00 Module Ten - The Fifth Improvement Concept (Continuous Improvement) 00:11:00 Module Eleven - The Improvement Toolkit 00:09:00 Module Twelve - Wrapping Up 00:10:00

Welcome to Print Production: Professional Training for Printing Jobs. In this course, you'll learn: Fundamentals of Print Production:Introduction to the printing industryHistorical perspective and evolution of printOverview of print technologies and methods Process of Print Production:Step-by-step breakdown of the print production workflowUnderstanding pre-press, press, and post-press processesTroubleshooting common issues in the production pipeline Tools of Print Production:In-depth exploration of industry-standard softwarePractical use of design and layout toolsOverview of hardware and machinery used in print production Understanding Colour:Color theory and its application in printColor spaces, models, and calibrationTechniques for achieving accurate and consistent color reproduction Binding and Finishing:Various binding methods and their applicationsFinishing techniques for different print materialsQuality control in binding and finishing processes Preparing Raster Images:Best practices for working with raster imagesImage resolution, color modes, and file formatsHands-on exercises for image optimization in print projects Understanding Fonts:Typography essentials for printFont selection and pairingHandling fonts in various design software Photoshop Production Tips:Advanced techniques for image manipulation and enhancementOptimizing images for printIntegration of Photoshop into the print production workflow Illustrator Production Tips:Vector graphics essentialsCreating print-ready illustrations and designsLeveraging Illustrator tools for efficient print production

Introduction to Exploration and Production for New Engineers and Non-Technical Professionals in Oil & Gas

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Exploration and production technology, equipment specification and processes have a unique language that must be conquered by executives such as you. A confident understanding of the technical jargon and a visual appreciation of the various pieces of equipment used provides for an overall 'big picture' of industry value chain. This serves as an excellent foundation for smooth communication and increased efficiency in inter-department project team efforts. Gain a comprehensive overview of the entire value chain and process of oil & gas upstream operations and business in this 3 full-day training course. Training Objectives By attending this industry fundamentals training course, participants will be better able to: Appreciate the dynamics of world energy demand & supply and its impact on pricing Understand the formation of petroleum reservoirs and basic geological considerations Examine the exploration process to gain an overview of the technical processes involved Gain a comprehensive overview of drilling activities - from pre-drilling preparation, through to well drilling, well evaluations and post drilling activities Get familiarised with the common production methods and the different stages of its processes Integrate your understanding of asset maintenance and downstream supply chain activities Better visualise through video presentations the various exploration equipment/ technologies and understand the major cost components Target Audience This course will be useful and applicable, but not limited to: Accounting Administration Business Development Commercial Construction E & P IT / Data Finance Finance & Treasury Health & Safety Human Resource Joint Venture Co-ordinators Legal Logistics Materials Planning Procurement Sales & Marketing Senior Management Sourcing Strategic Planning Supply Chain Tender Contract Course Level Basic or Foundation Training Methods Multi-media presentation methodology to enable better understanding and appreciation technical jargon and equipment applied in the field A pre-course questionnaire to help us focus on your key learning objectives Detailed reference manual for continuous learning and sharing Limited class size to ensure one to one interactivity Trainer Your expert course leader worked for BP for 28 years as a Research Associate and Team Leader, working on Feasibility Studies and acting as a trouble shooter covering all aspects of BPs businesses. These covered field Development Project in the North Sea and several novel resource recovery techniques which were taken from Concept to Field Pilot trials in Canada. His specific work in the offshore area covered Subsea Robotics / Automation, Seabed Production Concepts, Seabed Excavation Methods, Underwater Repair Techniques, Flexible Riser Studies and Maintenance Cost Reductions. After leaving BP in 1992, he continued working in the offshore oil industry through Azur Offshore Ltd, including activities in the assessment of Emerging and Novel Technologies, Technical and Economic Audits, Studies, Production Sharing Agreement Evaluations, Safety and Environmental issues. Clients have included Chevron UK, BP Exploration, British Gas, Technomare, Trident Consultants, Fina UK and Cameron France. He is a regular University lecturer at Crandfield School of Industrial Sciences (UK) and is a course Group Project external examiner for Crandfield. He also lectures on offshore oil industry activities at ENSIETA (France), the Technical University of Delft (Holland) and the Northern Territories University in Darwin (Australia). He is an active member of the UK Society for Underwater Technology (SUT) and serves on their Subsea Engineering and Operations Committee. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

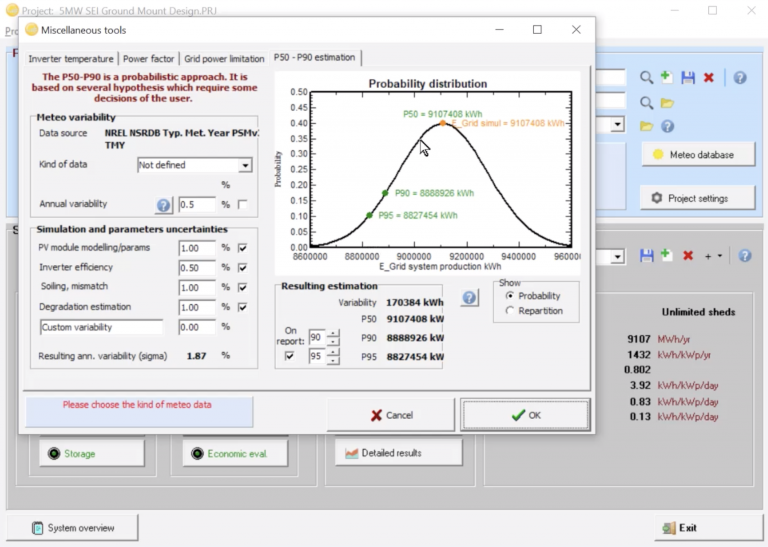

CE524: PVsyst for PV System Production Modeling

By Solar Energy International (SEI)

This short course is targeted towards beginning users, and will show you in detail how to get started creating accurate production estimates for any size PV system, from residential to large-scale. Learn how to find and import the correct meteorological data, create system variants for any size system, and accurately define the orientation, shading scene, and detailed system losses. By the end of this course you will be confidently simulating production and printing reports to share.

Step into the intricate world of supply chains, purchasing cycles, and procurement strategy with this expertly designed Production and Procurement Engineer Course. From understanding the foundations of supply chain operations to mastering supplier relationships, risk analysis, and e-procurement, this course offers a detailed look into the frameworks that keep modern businesses moving efficiently. Every module is shaped to reflect industry-relevant processes and systems used in today's engineering and procurement functions, making it an essential guide for professionals aiming to sharpen their capabilities in purchasing and supply coordination. Explore how procurement plays a strategic role in organisational success, with modules covering everything from competitive bidding and quality management to category oversight and digital procurement solutions. Whether you're handling supplier negotiations, managing inventory, or streamlining purchasing tools, this course offers a clear, structured journey through the key concepts and methods that define procurement excellence in engineering-led industries. Designed to be studied entirely online, it's tailored for those seeking a focused, professional route into advanced production and procurement functions. Key Benefits Accredited by CPD Instant e-certificate Fully online, interactive course Self-paced learning and laptop, tablet, smartphone-friendly 24/7 Learning Assistance Curriculum Module 01: Supply Chain Basics Module 02: Role of Procurement in an Organisation Module 03: The Purchasing Cycle Module 04: Purchasing Toolkits Module 05: Managing Competitive Bids Module 06: Quality Management Module 07: Supplier Relationship Management Module 08: Analysing and Reducing Risk in the Supply Chain Module 09: Improving Efficiency and Accuracy Module 10: Category Management Module 11: Inventory Management Module 12: E-procurement Course Assessment You will immediately be given access to a specifically crafted MCQ test upon completing an online module. For each test, the pass mark will be set to 60%. Certificate Once you've successfully completed your course, you will immediately be sent a digital certificate. Also, you can have your printed certificate delivered by post (shipping cost £3.99). Our certifications have no expiry dates, although we do recommend that you renew them every 12 months. CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? The Production and Procurement Engineer training is ideal for highly motivated individuals or teams who want to enhance their skills and efficiently skilled employees. Requirements There are no formal entry requirements for the course, with enrollment open to anyone! Career path Learn the essential skills and knowledge you need to excel in your professional life with the help & guidance from our Production and Procurement Engineer training. Certificates Certificate of completion Digital certificate - Included Certificate of completion Hard copy certificate - Included

SCM310 SAP Production Orders

By Nexus Human

Duration 5 Days 30 CPD hours This course is intended for The primary audience for this course are Application Consultants, Business Process Architects, and Business Process Owners/Team Leads/Power Users. Overview Participants learn how production orders are used, and which main system setting must be made for production order execution. In this course, students learn how production orders are used and which main system setting must be made for production order execution. Introduction to Production Orders Outlining SAP Supply Chain Management Outlining Production Orders Applying Production Orders in Supply Chain Management Order Processing and Order Structure Processing Production Orders Analyzing the Production Order Structure Order Creation Creating Production Orders Without Master Data Creating Production Orders Based on Planned Orders Creating Production Orders Without Planned Orders Defining Order Types Creating Production Orders with Master Data Scheduling Production Orders Costing of Production Orders Order Release Checking Material Availability Checking Capacity Availability Checking Production Resource/Tool Availability Planning Capacities Releasing Production Orders Order Documents Setting Up Order Print Control Printing Production Orders Material Staging Staging Material Withdrawing Material Confirmations Setting Parameters for Confirmations Executing Confirmations Good Receipt Preparing Goods Receipts Posting Goods Receipts Order Settlement, Archiving, & Deletion Settling Production Orders Archiving and Deleting Production Orders Information Systems and Automation Applying Information Systems Automating Production Orders and Mass Processing Applying Collective Orders Applying Trigger Points Extended Functionality and Enhancements Applying Order Split Applying Shift Reports and Shift Notes Applying Work-in-Process (WIP) Batches Applying SAP Execution Steps (XSteps) for Routings and Production Orders Outlining the Production Planning-Plant Data Collection (PP-PDC) Interface Outlining SAP Manufacturing Integration and Intelligence (SAP MII) in Shop Floor Control Applying Handling Units in Production

Subsea Production Engineering - Incorporating Subsea Tie-backs - Virtual Instructor Led Training

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual instructor Led Training (VILT) The Subsea Production Engineering Virtual instructor Led Training (VILT) course provides an overview of all of the functionalities and key interfaces of subsea equipment. The VILT course will refer to relevant industry engineering standards for subsea equipment, subsea tie-backs and critical operational requirements. The sessions will cover challenges associated with equipment design and installability, as well as a new module on subsea tie-backs. The primary learning objectives for this VILT course are met through a combination of interactive presentations, discussion and exercises. Training Objectives By the end of this VILT course, participants will be able to: Apply the requirements of related industry standards (API 6A/ 17D, API 17A etc.) engineering standards Understand the barrier and qualification requirements Identify the barriers in place given a specific mode of operation Evaluate and select which tree alternatives are valid based on the key design drivers Identify and describe the key design drivers Explain the importance of well kill rate Describe which tree alternatives are valid for certain scenarios based on an evaluation of the key tree design requirements Examine what effects subsurface requirements may have on tree design Understand the challenges associated with designing equipment for manufacturability and installability Recognise the implications of design changes to specific components and the effects on transportation and installation (such as what type of vessels, lifting equipment, and tools to use and the logistical requirements) Recognise the implication of design changes on manufacturability of subsea equipment Target Audience This VILT course provides a comprehensive understanding of the equipment used in subsea production systems. It is designed for petroleum engineers, production engineers, subsea project engineers and is also highly suitable for cost, planning, offshore installation and offshore operations engineers. Anyone directly or indirectly involved with subsea equipment will benefit from attending this VILT course - from engineers installing the equipment to procurement staff looking to understand more. Training Methods The VILT course will be delivered online in 4 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 4 half-day sessions, 4 hours per session (16 hours in total). Trainer Most of his working life, your expert course leader has been in a role that has enabled him to pass on skills and knowledge to others. A full-time role in Training and Development came about in 1996 with the offer to take up a full-time teaching post at Aberdeen College. In 1998, he was recruited by Kvaerner Oilfield Products, an Oil & Gas industry company, specialising in Subsea Control Systems, to develop and implement a Training & Competence program acceptable for its staff of over 600 and their client companies - a challenge he could not resist. In 2003, he broadened his horizons and became an independent Training & Development consultant. Building a reputation for delivering training and development to the Oil & Gas industry to the highest standards, he later joined Jee Ltd, a leading subsea engineering and training company based in Aberdeen. He was tasked with a wide portfolio of training, coaching & mentoring to achieve high levels of competence for the client's staff and customers. He is also a Science and Engineering Ambassador (Scotland), promoting the need for engineers and technicians for Scotland's industries, a frequent consultant to the European Economic & Social Committee for standardising Vocational Skills training and competence throughout the EU. He holds memberships in the Society of Operations Engineers, Chartered Institute of Personnel & Development and Society of Underwater Technologies. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

In today's digital age, understanding Audio Recording Equipment is crucial for anyone interested in sound engineering or media production. This course dives deep into essential topics such as vocal microphone techniques, sound interfaces, studio setup, and editing software, all of which are fundamental in the world of audio recording. Mastering these skills not only enhances your ability to produce high-quality recordings but also opens doors to various career opportunities, especially in the UK where the demand for skilled audio engineers is significant. Professionals in this field can expect competitive salaries, with averages ranging from £25,000 to £35,000 annually, depending on experience and specialization. Learning about audio recording equipment is indispensable whether you're pursuing a career in music production, podcasting, or film sound design. The advantages of gaining expertise in this sector are evident in its growth, as the demand for skilled professionals continues to rise by 8% annually. This trend underscores the increasing reliance on audio technology across industries, making your skills in audio recording equipment not just valuable but essential in today's job market. Key Features: CPD Certified Audio Recording Equipment Course Free Certificate Developed by Specialist Lifetime Access Course Curriculum Module 01: Overview of Voice Over Gear Module 02: Vocal Microphone Techniques Module 03: Earpieces and Monitoring Solutions Module 04: Sound Interfaces and Preamplifiers Module 05: Studio Ambiance and Setup Essentials Module 06: Software for Voice Over and Editing Utilities Module 07: Maintenance and Troubleshooting for Audio Equipment Learning Outcomes: Master techniques for optimal vocal clarity with microphone handling expertise. Achieve precision in sound monitoring through efficient earpiece and monitoring solutions. Navigate sound interfaces and preamplifiers to enhance audio recording proficiency. Create a conducive studio environment with knowledge of ambiance and setup. Harness the power of editing utilities for seamless voice-over production. Acquire troubleshooting skills for maintaining and optimizing audio recording equipment. CPD 10 CPD hours / points Accredited by CPD Quality Standards Who is this course for? This Audio Recording Equipment course is accessible to anyone eager to learn more about this topic. Through this course, you'll gain a solid understanding of Audio Recording Equipment. Moreover, this course is ideal for: Aspiring sound engineers seeking advanced audio recording equipment knowledge. Content creators desiring to enhance their voice-over production capabilities. Podcasters looking to elevate the quality of their audio recordings. Musicians aiming to optimize studio setups for high-quality sound production. Video producers interested in refining audio post-production skills. Requirements There are no requirements needed to enrol into this Audio Recording Equipment course. We welcome individuals from all backgrounds and levels of experience to enrol into this Audio Recording Equipment course. Career path After finishing this Audio Recording Equipment course you will have multiple job opportunities waiting for you. Some of the following Job sectors of Audio Recording Equipment are: Audio Engineer - £25K to 45K/year. Sound Designer - £22K to 50K/year. Podcast Producer - £20K to 40K/year. Studio Technician - £18K to 35K/year. Broadcast Technician - £20K to 38K/year. Certificates Digital certificate Digital certificate - Included Certificate of Completion Digital certificate - Included Will be downloadable when all lectures have been completed.

Professional Certificate Course in Production and Cost Analysis and Estimation in London 2024

4.9(261)By Metropolitan School of Business & Management UK

The aim of the "Production and Cost Analysis and Estimation" course is to provide students with a comprehensive understanding of the production process, the cost structure of a firm, and the methods used to estimate costs and production functions.After the successful completion of the course, you will be able to: Understand the Classical Production Theory. Understand the Optimum Factor of Combinations. Understand the Price Elasticity of Supply. Understand the Short-run and Long-run Cost Theories. Understand the Break-even-analysis, Cost-Benefit analysis, Outscoring, and Cost. Understand the Learning curve, Product innovation, and Process Innovation Life-Cycle Model. This economics course focuses on the analysis of production functions, cost functions, and the relationship between input and output. The course covers topics such as marginal cost, average total cost, and average variable cost, as well as the estimation techniques of cost functions and production functions. Students will learn about how firms make production decisions and how they can estimate and optimize their production costs to achieve maximum profitability. This course is an economics course that focuses on the analysis of production functions, cost functions, and the relationship between input and output. The course covers topics such as marginal cost, average total cost, and average variable cost, as well as the estimation techniques of cost functions and production functions. Students will learn about how firms make production decisions and how they can estimate and optimize their costs of production to achieve maximum profitability. VIDEO - Course Structure and Assessment Guidelines Watch this video to gain further insight. Navigating the MSBM Study Portal Watch this video to gain further insight. Interacting with Lectures/Learning Components Watch this video to gain further insight. Production and Cost Analysis & Estimation Self-paced pre-recorded learning content on this topic. Production And Cost Analysis And Estimation Put your knowledge to the test with this quiz. Read each question carefully and choose the response that you feel is correct. All MSBM courses are accredited by the relevant partners and awarding bodies. Please refer to MSBM accreditation in about us for more details. There are no strict entry requirements for this course. Work experience will be added advantage to understanding the content of the course. The certificate is designed to enhance the learner's knowledge in the field. This certificate is for everyone eager to know more and get updated on current ideas in their respective field. We recommend this certificate for the following audience. Business Analyst Financial Analyst Operations Manager Production Planner Cost Estimator Supply Chain Manager Management Consultant Economist Average Completion Time 2 Weeks Accreditation 3 CPD Hours Level Advanced Start Time Anytime 100% Online Study online with ease. Unlimited Access 24/7 unlimited access with pre-recorded lectures. Low Fees Our fees are low and easy to pay online.

Youtube and Instagram Video Production Training

By Course Cloud

Immerse yourself in the ultimate guide on Youtube and Instagram Video Production Training. This course empowers you to navigate the complexities of video production, starting with preparation: from selecting a compelling topic to choosing the right equipment. Delve into detailed filming techniques, ensuring you're adept in varied camera setups, filming in segments, and even troubleshooting when things don't go as planned. Navigate the intricacies of video importing, ensuring your content remains secure with robust storage and backup solutions. Discover the world of editing, exploring dynamic software options and accessing rich content libraries for a polished final product. Conclude your learning journey with expertise in rendering, exporting, and effectively uploading your masterpiece to digital platforms. Become the video content creator the digital world awaits! Career Path Content Creator: Craft unique content for YouTube and Instagram, driving engagement and revenue. Video Editor: Perfect videos in post-production for creators or studios. Production Adviser: Guide on equipment and shooting strategy for budding creators. Digital Marketing: Integrate video strategies in marketing campaigns to boost brand presence. Video Archivist: Manage video storage and cataloguing, ensuring content longevity for productions.

Search By Location

- Production Courses in London

- Production Courses in Birmingham

- Production Courses in Glasgow

- Production Courses in Liverpool

- Production Courses in Bristol

- Production Courses in Manchester

- Production Courses in Sheffield

- Production Courses in Leeds

- Production Courses in Edinburgh

- Production Courses in Leicester

- Production Courses in Coventry

- Production Courses in Bradford

- Production Courses in Cardiff

- Production Courses in Belfast

- Production Courses in Nottingham