- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

57504 Courses

H&S for FM (In-House)

By The In House Training Company

This workshop has been designed to help managers understand their responsibilities and what they need to do to ensure compliance with current workplace legislation - including the fire safety and CDM regulations. The day will cover the legal background - including an appreciation of how safety legislation has evolved and why; the logic behind recent developments and the implications for staff and employers; key areas of current legislation; roles and responsibilities in health and safety management, including monitoring contractors and suppliers effectively; implementing sound health and safety policies and procedures; getting staff on board, and implementing effective systems. Also, recognising potential risks and hazards and developing strategies to minimise their impact in the workplace. This course will give participants an understanding of: The broader context of the key areas of health and safety regulation which apply to your organisation Existing health and safety practice and guide them in how to shape and implement an effective health and safety policy What they should do and the procedures to support it Potential areas of risk in the workplace - and how to take action to minimise the threat to staff safety How sound health and safety processes can contribute to business performance 1 Understanding the workplace legislation Overview of health and safety and workplace legislation Compliance, the role of the facilities manager, and who is accountable? Breakout session to discuss where we are now and to highlight issues of concern Applying required policies and procedures Developing and implementation/review of the safety policy Communicating with users, clients and contractors Health and safety manual 'Selling' health and safety 2 Key legislation - a practical working guide Asbestos Regulations Construction (Design and Management) Regulations 2007 / 2015 Control of Substances Hazardous to Health (COSHH) Regulations Disability Discrimination Act (DDA) Display Screen Equipment (DSE) Regulations 1992 Electricity at Work Regulations 1989 Fire Precautions (Workplace ) Regulations 2006 Health and Safety (Consultation with Employees) Regulations 1996 Health and Safety (First Aid) Regulations 1981 Health and Safety at Work etc. Act 1974 Management of Health and Safety at Work Regulations 1992 Manual Handling Operations Regulations 1992 Portable Appliance Testing (PAT) Provision and Use of Work Equipment Regulations 1992 REACH - Registration, Evaluation, Authorisation and restriction of Chemicals Reporting of Injuries, Diseases, and Dangerous Occurrences Regulations (RIDDOR) 1995 Waste Electrical and Electronic Equipment (WEEE) Regulations 2006 Work Equipment Regulations 3 Controlling contractors Understanding the Regulations Selecting and assessing contractors Understanding and setting accountability Why a method statement? How to apply a permit to work system Safe systems of work Round-table discussion to bring out issues from participants' own experience 4 Risk assessment Understanding your hazards Identifying specialist areas How to undertake these assessments Implementation of sound systems and processes Syndicate exercise identifying where assessments are needed and carrying out assessments 5 Keeping the work environment safe Sick building syndrome and legionella Asbestos Waste management Pest control Provisions for first aid Accident reporting and investigation At-work driver safety Security 6 Fire safety Understanding the Regulatory Reform Fire Safety Order Fire certificates The fire risk assessment Testing fire-fighting equipment? Emergency procedures Workshop to examine the procedures for dealing with different types of emergencies 7 Ergonomics programme Ergonomics - important or irrelevant? Are you complying with HSE regulations? Furniture and equipment Display screen equipment assessments Homeworking - your concern or not? Syndicate exercise to review what to do when relocating or refurbishing an office 8 Inspecting and auditing Role of Health and Safety Executive Inspectors - 'be prepared' FM role Staff/trade union involvement Independent audits Records and reports Communicating the results 9 Action plan Participants to list actions they need to take after the course

English Language Courses

By Bath Academy

English Language courses at Bath Academy are suitable for every type of student. Join classes every Monday.

The course helps participants understand the role of demand and inventory planning in the wider context of supply chain management. It aims to demonstrate how to improve the alignment between supply and demand to maintain good levels of customer service and on-shelf availability whilst eliminating excess stock and reducing inventory investment. PARTICIPANTS WILL LEARN HOW TO: • Understand the role of demand management and its benefits • Identify the key demand characteristics and patterns; learn how to use them to improve forecast accuracy • Develop an understanding of key qualitative and quantitative forecasting methods • Learn how to conduct fundamental inventory analyses with a view to achieving the appropriate trade-off between stock and service level COURSE TOPICS INCLUDE: The role of Demand Management • The end-to-end view of Supply Chain Management • Demand Characteristics and the Product Life Cycle • Demand patterns • Push and pull systems Background to forecasting • The forecasting Process • Time-series methods of forecasting • Calculating forecast errors Inventory Analysis • Categorisation of stock • ABC Analysis • Economic order quantity and minimum order quantity • Safety stock and stock cover Inventory Management • Materials requirements planning (MRP) • Stock replenishment systems • Practical inventory management • The cost of managing stock

NVQ DIPLOMA IN INSULATION AND BUILDING TREATMENTS (CONSTRUCTION)

By Oscar Onsite

REFERENCE CODE 603/7493/7 COURSE LEVEL NVQ Level 2 THIS COURSE IS AVAILABLE IN Course Overview The Level 2 NVQ in Insulation & Building treatments is for those who work with different types of insulation and building treatments and want to prove their competence in one or more of the following areas: Wood preserving and damp-proofing, Wall Tie replacement, Cavity Wall insulation, Solid Floor insulation, Under Floor insulation and Cold Roof insulation. There is also a Level 2 qualification available that may be more suitable for those in the sector with a greater degree of experience or level of responsibility

Commissioning of Combined Cycle Power Plants

By EnergyEdge - Training for a Sustainable Energy Future

About this Course This 5 full-day course provides a comprehensive understanding of all the commissioning procedures for combined cycle power plants. The Commissioning Management System (CMS) of combined cycle power plants is covered in detail in this course. This includes all the commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report. The course provides also a thorough understanding of all the commissioning requirements for gas turbines, steam turbines and auxiliaries, generator and auxiliaries, electrical equipment, switchgear equipment, switchgear and transformers. All the stages of the commissioning procedure are covered in-depth in this course. This includes preparation - planning various activities, pre-commissioning checks and tests, typical commissioning schedule, detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant, instrumentation, trial run of the equipment, safety and precautions, commissioning of combined cycle power plant systems, safety rules clearance certificates, procedure for the control and handling of defects, commissioning reports, operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test. This course is a MUST for anyone who is involved in the pre-commissioning or commissioning of any combined cycle power plant equipment because it provides detailed pre-commissioning checks and tests, and detailed tests and commissioning procedures and instructions for every component in a combined cycle power plant. In addition, the seminar provides an in-depth coverage of all preparation, planning activities, commissioning schedules, trial run of each combined cycle power plant equipment, safety and precautions, safety rules clearance certificates, procedures for handling defects, and commissioning reports. Training Objectives Pre-commissioning Checks and Tests, Detailed Tests and Commissioning Procedures and Instructions for Every Equipment in Combined Cycle Power Plants: Gain a thorough understanding of all pre-commissioning checks and tests, and all commissioning procedures and instructions for every equipment in combined cycle power plants Commissioning Management System (CMS) of Combined Cycle Power Plants: Discover the benefits of the CMS of combined cycle power plants including all commissioning procedures and documents, purpose of commissioning, responsibilities, system description, organization, working parties, test teams, documentation, testing and commissioning schedules, test reports, safety, plant certification, and plant completion report Commissioning Procedures and Instructions for Heat Recovery Steam Generators, Air Blow and Steam Blow of Steam and Gas Piping in Combined Cycle Power Plants: Learn about the commissioning procedures and instructions for heat recovery steam generators, chemical cleaning of heat recovery steam generators, air blow and gas blow of steam and gas piping in combined cycle power plants, safety valve setting and soot blowers Commissioning Procedures and Instructions for Gas Turbines and Steam Turbines: Gain a thorough understanding of all the commissioning procedures and instructions for gas and steam turbines and auxiliaries including acid cleaning of oil pipelines, lubrication and governing system (oil flushing and hydraulic testing), jacking oil system, governing system, regenerative system, barring gear, vacuum tightness test, first rolling of turbine and data logging Commissioning Procedures and Instructions for Generator and Auxiliaries: Discover all the commissioning procedures and instructions for generator and auxiliaries including generator, seal oil system, hydrogen gas system, stator water system, rolling and start-up of generators Commissioning Procedures and Instructions for Electrical Equipment: Learn about all the commissioning procedures and instructions for electrical equipment including switchyard equipment, switchgear, transformers and motors Operational Testing, Performance Testing, Heat Rate Testing, Emission Testing of Combine Cycle Power Plants: Gain a thorough understanding of operational testing, first fire, generator synchronization, performance testing, heat rate testing, emission testing, contract testing, CO2 concentration tests, electrical full-load rejection test, duct burner testing, partial load stability test, and reliability test of combined cycle power plants Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

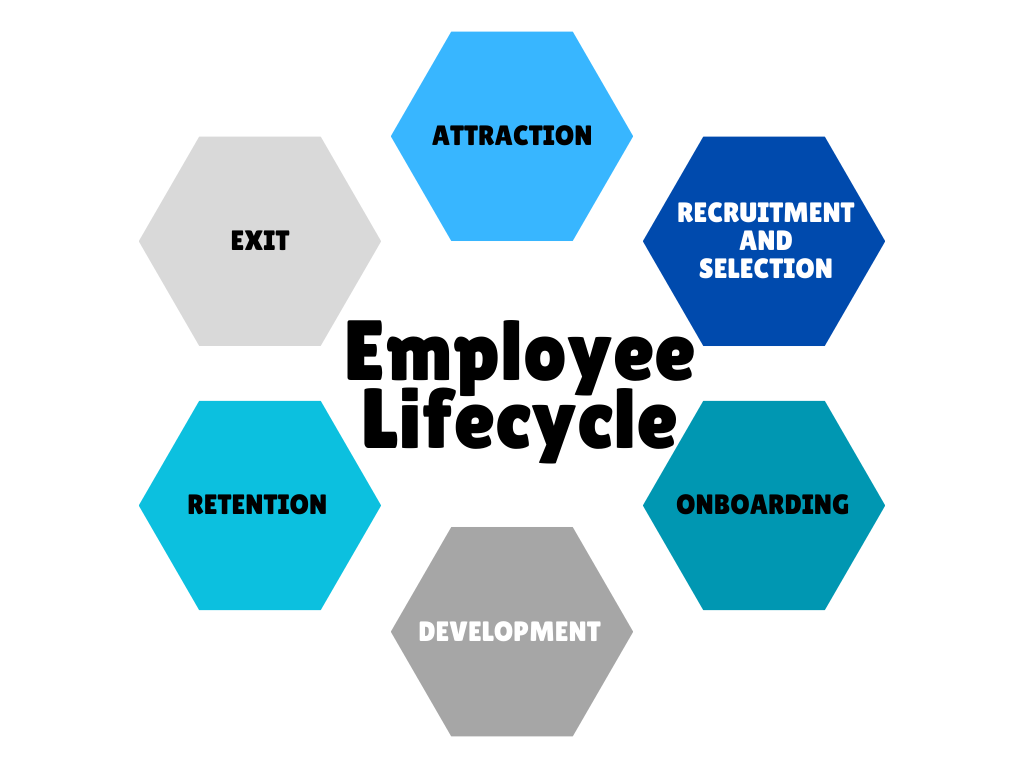

Employee Lifecycle

By Blue Sky Professional Development

A short online course introducing the concept of the Employee Lifecycle and an overview of each stage.

Overview of Telehandler Training Course Telehandler Training or Telehandler Courses is an essential program designed to equip operators with the necessary skills and knowledge to safely and efficiently operate telehandlers. These versatile machines, commonly used in agriculture, construction, and warehousing, require precise handling due to their complex controls and varied load capacities. Our Telehandler Courses will help you achieve your goal to be a successful Telehandler Operator. The importance of comprehensive telehandler training cannot be overstated. It ensures that operators are well-versed in both the theoretical and practical aspects of handling these machines, significantly reducing the risk of accidents and injuries on the job. Moreover, proper Telehandler training aids in maximising the operational efficiency of telehandlers, which can contribute to the timely completion of projects and the effective management of resources. In various industries, telehandlers play a critical role in lifting and transporting heavy materials over obstacles and uneven terrain, making the Telehandler course crucial for anyone involved in operations that require heavy lifting and material handling. The Telehandler courses covers a range of topics, including safety regulations, operational techniques, maintenance basics, and troubleshooting common issues, ensuring that all participants are prepared to handle the demands of operating a telehandler in any setting. Booking the Telehandler Training couldn’t be easier. Book Now

PgMP Exam Prep: Virtual In-House Training

By IIL Europe Ltd

PfMP® Exam Prep: Virtual In-House Training This is an intensive PfMP® Exam preparation course. This learning experience guides you through the multi-faceted discipline of portfolio management by focusing on the related technical, leadership, and business skills required to navigate it in the real world. First and foremost, this is an intensive PfMP® exam preparation course. Over the course, we go beyond exam prep to provide selected practice in applying key portfolio management skills, tools, and techniques. This learning experience guides you through the multi-faceted discipline of portfolio management by focusing on the related technical, leadership, and business skills required to navigate it in the real world. The journey zooms in and out between governance context and specific operational activities. The ultimate goal is practical application, with the bonus of certification along the way. What You Will Learn By the end of this program, you will be able to: Align and manage the portfolio, strategically, to satisfy organizational objectives and priorities, through benefit realization Articulate and emulate the role of a portfolio manager Apply the principles and skills of a portfolio manager to your real-world environment Study and prepare for the PfMP® Examination Apply for the certification, per the PMI PfMP Handbook and pass the initial panel review on your application Getting Started Course Overview Details of the PfMP® Certification process Foundation Concepts Projects, program, and portfolios A portfolio management process Strategy and value The role of the portfolio manager The role of key stakeholders Life cycle management The Portfolio Life Cycle Overview of Life Cycle Portfolio Management Information System (PMIS) Governance within the Portfolio Life Cycle Strategic Management Strategy concepts Supporting documentation and the strategic plan Planning and optimization Organizational risk appetite Managing strategic change Governance Management Overview and Guiding Principles The Concept of Governance Effective Design Factors Governance Roles Capacity and Capability Management Overview and Guiding Principles Capacity Management and Planning Supply and Demand (Management and Optimization) Organization Capabilities (Assessment and Development) Performance Management (Reporting, Analytics, and Balance) Stakeholder Engagement The Importance of Stakeholders Overview and Guiding Principles Definition and Identification Analysis and Planning Communications Approaches and Management Value Management Overview (Guiding Principles, Definition, and Components) Negotiating Expected Value Maximizing Value Assuring Value Realizing Value Measuring and Reporting Value A Look at Tools Risk Management Overview and Guiding Principles Portfolio Risk Planning Portfolio Risk Identification Portfolio Risk Assessment Portfolio Risk Response Examination Content Outline (ECO) Overview Structure Strategic Tasks Mapping Governance Tasks Mapping Performance Tasks Mapping Risk Tasks Mapping Communication Tasks Mapping List of Knowledge and Skills Exam Prep and Practice Overview Documenting experience Submitting the application Preparing to sit for the exam

NVQ DIPLOMA IN SITE LOGISTICS OPERATIONS (CONSTRUCTION)

By Oscar Onsite

REFERENCE CODE 603/6964/4 COURSE LEVEL NVQ Level 2 THIS COURSE IS AVAILABLE IN Course Overview This qualification enables the learner to demonstrate and recognise their skills, knowledge and understanding and to demonstrate their competence in a real workplace environment so that they can work in the Site Logistics Operations sector within the construction industry. All work must be completed following Industry recognised Safe Working Practices and in accordance with relevant legislation. This qualification is at Level 2, although some units may be at different levels and should be taken by those who are fully trained to deal with routine assignments. Candidates should require minimum supervision in undertaking the job. The qualification has been developed in a way to allow employees from companies of all sizes and specialisms equal opportunity to complete.

NVQ DIPLOMA IN CONSTRUCTION OPERATIONS AND CIVIL ENGINEERING – CONSTRUCTION OPERATIONS

By Oscar Onsite

REFERENCE CODE 600/6515/1 COURSE LEVEL NVQ Level 2 THIS COURSE IS AVAILABLE IN Course Overview This qualification is at Level 2, although some units may be at different levels and should be taken by those who are fully trained to deal with routine assignments. Candidates should require minimum supervision in undertaking the job. The qualification has been developed in a way to allow employees from companies of all sizes and specialisms equal opportunity to complete. This qualification is specifically aimed at those carrying out general construction operations work; there is a Level 2 qualification for those involved in maintenance along with a suite of specific qualifications in a wide range of construction occupations available.

Search By Location

- Course Courses in London

- Course Courses in Birmingham

- Course Courses in Glasgow

- Course Courses in Liverpool

- Course Courses in Bristol

- Course Courses in Manchester

- Course Courses in Sheffield

- Course Courses in Leeds

- Course Courses in Edinburgh

- Course Courses in Leicester

- Course Courses in Coventry

- Course Courses in Bradford

- Course Courses in Cardiff

- Course Courses in Belfast

- Course Courses in Nottingham