- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

1288 Courses

AZ-801T00 Configuring Windows Server Hybrid Advanced Services

By Nexus Human

Duration 4 Days 24 CPD hours This course is intended for This four-day course is intended for Windows Server Hybrid Administrators who have experience working with Windows Server and want to extend the capabilities of their on-premises environments by combining on-premises and hybrid technologies. Windows Server Hybrid Administrators who already implement and manage on-premises core technologies want to secure and protect their environments, migrate virtual and physical workloads to Azure Iaas, enable a highly available, fully redundant environment, and perform monitoring and troubleshooting. This course teaches IT Professionals to configure advanced Windows Server services using on-premises, hybrid, and cloud technologies. The course teaches IT Professionals how to leverage the hybrid capabilities of Azure, how to migrate virtual and physical server workloads to Azure IaaS, and how to secure Azure VMs running Windows Server. The course also teaches IT Professionals how to perform tasks related to high availability, troubleshooting, and disaster recovery. The course highlights administrative tools and technologies including Windows Admin Center, PowerShell, Azure Arc, Azure Automation Update Management, Microsoft Defender for Identity, Azure Security Center, Azure Migrate, and Azure Monitor. Prerequisites An understanding of the following concepts as related to Windows Server technologies: High availability and disaster recovery Automation Monitoring Troubleshooting 1 - Secure Windows Server user accounts Configure user account rights Protect user accounts with the Protected Users group Describe Windows Defender Credential Guard Block NTLM authentication Locate problematic accounts 2 - Hardening Windows Server Describe Local Password Administrator Solution Configure Privileged Access Workstations Secure domain controllers Analyze security configuration with Security Compliance Toolkit Secure SMB traffic 3 - Windows Server update management Explore Windows Update Outline Windows Server Update Services server deployment options Define Windows Server Update Services update management process Describe the process of Update Management 4 - Secure Windows Server DNS Implement split-horizon DNS Create DNS policies Implement DNS policies Secure Windows Server DNS Implement DNSSEC 5 - Implement Windows Server IaaS VM network security Implement network security groups and Windows IaaS VMs Implement adaptive network hardening Implement Azure Firewall and Windows IaaS VMs Implement Windows firewall with Windows Server IaaS VMs Choose the appropriate filtering solution Deploy and configure Azure firewall using the Azure portal Capture network traffic with network watcher Log network traffic to and from a VM using the Azure portal 6 - Audit the security of Windows Server IaaS Virtual Machines Describe Azure Security Center Enable Azure Security Center in hybrid environments Implement and assess security policies Protect your resources with Azure Security Center Implement Azure Sentinel 7 - Manage Azure updates Describe update management Enable update management Deploy updates View update assessments Manage updates for your Azure Virtual Machines 8 - Create and implement application allowlists with adaptive application control Describe adaptive application control Implement adaptive application control policies 9 - Configure BitLocker disk encryption for Windows IaaS Virtual Machines Describe Azure Disk Encryption and server-side encryption Configure Key Vault for Azure Disk Encryption Encrypt Azure IaaS Virtual Machine hard disks Back up and recover data from encrypted disks Create and encrypt a Windows Virtual Machine 10 - Implement change tracking and file integrity monitoring for Windows IaaS VMs Implement Change Tracking and Inventory Manage Change Tracking and Inventory Manage tracked files Implement File Integrity Monitoring Select and monitor entities Use File Integrity Monitoring 11 - Introduction to Cluster Shared Volumes Determine the functionality of Cluster Shared Volumes Explore the architecture and components of Cluster Shared Volumes Implement Cluster Shared Volumes 12 - Implement Windows Server failover clustering Define Windows Server failover clustering Plan Windows Server failover clustering Implement Windows Server failover clustering Manage Windows Server failover clustering Implement stretch clusters Define cluster sets 13 - Implement high availability of Windows Server VMs Select high-availability options for Hyper-V Consider network load balancing for Hyper-V VMs Implement Hyper-V VM live migration Implement Hyper-V VMs storage migration 14 - Implement Windows Server File Server high availability Explore the Windows Server File Server high-availability options Define Cluster Shared Volumes Implement Scale-Out File Server Implement Storage Replica 15 - Implement scale and high availability with Windows Server VM Describe virtual machine scale sets Implement scaling Implement load-balancing VMs Create a virtual machine scale set in the Azure portal Describe Azure Site Recovery Implement Azure Site Recovery 16 - Implement Hyper-V Replica Define Hyper-V Replica Plan for Hyper-V Replica Configure and implement Hyper-V Replica Define extended replication Define Azure Site Recovery Implement Site Recovery from on-premises site to Azure Implement Site Recovery from on-premises site to on-premises site 17 - Protect your on-premises infrastructure from disasters with Azure Site Recovery Azure Site Recovery overview Workloads supported for protection with Azure Site Recovery Run a disaster recovery drill Failover and failback 18 - Implement hybrid backup and recovery with Windows Server IaaS Describe Azure Backup Implement recovery vaults Implement Azure Backup policies Recover Windows IaaS Virtual Machines Perform file and folder recovery Perform backup and restore of on-premises workloads Manage Azure Virtual Machine backups with Azure Backup service 19 - Protect your Azure infrastructure with Azure Site Recovery What is Azure Site Recovery Prepare for disaster recovery with Azure Site Recovery Run a disaster recovery drill Failover and failback using Azure Site Recovery 20 - Protect your virtual machines by using Azure Backup Azure Backup features and scenarios Back up an Azure virtual machine by using Azure Backup Restore virtual machine data 21 - Active Directory Domain Services migration Examine upgrade vs. migration Upgrade a previous version of Active Directory Domain Services to Windows Server 2022 Migrate to Active Directory Domain Services in Windows Server 2022 from a previous version Explore the Active Directory Migration Tool 22 - Migrate file server workloads using Storage Migration Service Storage Migration Service overview and usage scenarios Storage migration requirements Migrate a server with Storage migration Evaluate storage migration considerations 23 - Migrate Windows Server roles Describe the Windows Server Migration Tools Install the Migration Tools Migrate roles using the Migration Tools 24 - Migrate on-premises Windows Server instances to Azure IaaS virtual machines Plan your migration Describe Azure Migrate Perform server assessment Assess physical servers with Azure Migrate Migrate Windows Server workloads by using Azure Migrate 25 - Upgrade and migrate Windows Server IaaS virtual machines Describe Azure Migrate Migrate Windows Server workloads by using Azure Migrate Describe storage migration Migrate file servers by using Storage Migration Service 26 - Containerize and migrate ASP.NET applications to Azure App Service Azure Migrate App Containerization overview 27 - Monitor Windows Server performance Use Performance Monitor to identify performance problems Use Resource Monitor to review current resource usage Review reliability with Reliability Monitor Implement a performance monitoring methodology Use Data Collector Sets to analyze server performance Monitor network infrastructure services Monitor virtual machines running Windows Server Monitor performance with Windows Admin Center Use System Insights to help predict future capacity issues Optimize the performance of Windows Server 28 - Manage and monitor Windows Server event logs Describe Windows Server event logs Use Windows Admin Center to review logs Use Server Manager to review logs Use custom views Implement event log subscriptions 29 - Implement Windows Server auditing and diagnostics Describe basic auditing categories Describe advanced categories Log user access Enable setup and boot event collection 30 - Troubleshoot Active Directory Recover objects from the AD recycle bin Recover the AD DS database Recover SYSVOL Troubleshoot AD DS replication Troubleshoot hybrid authentication issues 31 - Monitor Windows Server IaaS Virtual Machines and hybrid instances Enable Azure Monitor for Virtual Machines Monitor an Azure Virtual Machine with Azure Monitor Enable Azure Monitor in hybrid scenarios Collect data from a Windows computer in a hybrid environment Integrate Azure Monitor with Microsoft Operations Manager 32 - Monitor your Azure virtual machines with Azure Monitor Monitoring for Azure VMs Monitor VM host data Use Metrics Explorer to view detailed host metrics Collect client performance counters by using VM insights Collect VM client event logs 33 - Troubleshoot on-premises and hybrid networking Diagnose DHCP proble

Total STP training course description The Spanning Tree Protocol (STP) dates from 1985. This course explores in depth how the protocol works and the implications this has on network performance. We also study STP variants including 802.1w (RSTP) and 802.1s (MSTP). What will you learn Explain how STP works. Explain how RSTP works. Explain how MSTP works. Troubleshoot STP and variants. Total STP training course details Who will benefit: Technical network staff. Prerequisites: Definitive Ethernet switching for engineers Duration 1 day Total STP training course contents STP What is 802.1D, what is STP, resilience, broadcast storms, forwarding and blocking, single path. Hands on Impact of broadcast storms, enabling disabling STP. Operation STP frames, BPDUs, root bridge election, blocked ports, root ports, designated ports. STP path costs. Hands on Analysing STP, troubleshooting implications. Topology changes Hello timer, Forward delay timer, max age timer, Topology Change Notification (TCN) BPDU. Hands on STP convergence. STP enhancements and tuning Bridge ID, Bridge priority, port priority, 30 second delay, Edge ports, PortFast, root guard, loop guard, BPDU guard. Hands on Root bridge positioning, improving STP convergence. RSTP 802.1w, Improvements, convergence times. RSTP bridge port roles, RSTP switch port states. Edge ports, link ports. Hands on RSTP configuration and convergence. VLANs and STP Access/untagged ports, trunk/tagged ports, PVST, PVST+, RPVST, MISTP, MSTP and 802.1s. MSTP BPDUs. Instances, Load balancing, impact on CPU. Hands on MSTP load balancing. Interoperability Regions, Virtual bridges, domains. Hands on STP, RSTP and MSTP interoperation.

Natural Gas Properties & Sulphur Recovery

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) This 5 half-day VILT course will comprehensively cover the technical aspects of gas processing. The scope will be from the wellhead through the typical gas processing plant and discuss gas gathering (pipeline hydraulics), natural gas treating (H2S, CO2 removal), acid gas injection and sulfur recovery. One unique aspect of this training course is the operations and troubleshooting discussions in each module. This VILT course is suited to technical personnel or technical management. Training Objectives After the completion of this VILT course, participants will be able to: Grasp the key specifications of natural gas and liquid products Understand the physical and transport properties of gases and liquids and liquid-vapor phase behavior Explore the various technologies for processing natural gas and to make the specifications Examine the design of the technologies Learn how to diagnose operating problems to keep facilities running reliably Target Audience This VILT course is intended for all surface technical personnel such as process engineers & technologists, facility engineers and production engineers & technologists. This VILT course will greatly benefit but not limited to: Process, petroleum and production engineers Field operators and technicians Personnel involved in gas treatment and processing Managers and Supervisors involved with gas processing operations Course Level Basic or Foundation Intermediate Training Methods The VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 5 half-day sessions, 4 hours per session (20 hours in total). The maximum number of participants for this course is 20 persons. Case studies and Exercises: This VILT course will use actual case references throughout its duration in various forms. This will allow the application of the participants' newly-acquired knowledge. Case studies also stimulate independent thinking and discussion among the participants Trainer Your expert course leader has written several papers that have been published in both academic and industry journals. He has over 30 years of industry experience, specializing in gas processing (pipeline hydraulics, separation, dehydration, treating, sulphur recovery and refrigeration processes) and also has experience with crude oil dehydration, stabilization and micro-refining topping plants. He has experience with developing new technology and is recently involved in lithium, waste biomass and used motor oil pyrolysis and geothermal projects. He has recognized expertise in thermodynamics and physical and transport properties of fluids. He has consulted for several EPC and operating companies through his company Chem-Pet Process Tech., and currently holds the role of Director of Technology in an integrated engineering and solutions provider to the energy industry. He is currently involved with a small power-based carbon capture project as well as helping clients determine the best options for utilities decisions. He has been involved with CO2 dehydration and CO2 flood gas treating as well as acid gas injection projects for several years. Highlighted Achievements: Developed ORC geothermal model to determine the available power from wells in Alberta Acting on the Technical Advisory Board for E3 Metals, extracting lithium from formation water. Acted as a Subject Matter Expert for assessing the performance of the Plains Midstream Canada, Empress 1 Deep Cut Straddle Plant in a potential litigation. Acted as an Expert Witness for JL Transportation patent defence of a dense phase technology. Process engineer lead on the addition of the new Orloff gas plant for Deltastream. Also troubleshooted the oil battery shipping pump, plate exchanger and FWKO and treater. Evaluated gas processing and sulphur recovery options for new feeds to the Zhaikmunai Zelenovsky Gas Plant, Kazakhstan (with PM Lucas, Serbia). Completed capacity analysis for hydrocarbon dew point versus liquid recovery of three trains at Birchcliff Pouce Coupe facility including amine unit, refrigerated gas plant and acid gas injection. Completed process design for CO2 flue gas dehydration for Husky Energy Inc (with Status Engineering) Provided simulations of EnCana Foster Creek and Christina Lake and Husky McMullen SAGD facilities (with Vista Projects). Performed process engineering for Cenovus Pelican Lake SAGD pilot (with GRB Engineering) Bear Lake heavy oil polymer injection pilot (with GRB Engineering). Lead process engineer on the design of IEC Kerrobert crude oil micro-refinery (topping plant). Provided engineering support and troubleshooting for Enerchem Slave Lake Crude tower and product blending (with Status Engineering). POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Description Basic Electricity Diploma Introducing the Basic Electricity Diploma, an expertly designed online course crafted to impart foundational knowledge and skills surrounding the realm of electricity. This course is tailored to meet the ever-evolving needs of individuals seeking to understand the core principles of electricity, from its safe application to advanced troubleshooting techniques. Every budding electrician, enthusiast, or professional aiming to refresh their knowledge should consider the Basic Electricity Diploma as an essential stepping stone. The content is not just a compilation of theory; it aims to prepare the learner for real-world application. The course starts with a pivotal module on Electrical Safety. Ensuring safety is not just a protocol, but a crucial part of working with electricity. This module ensures that students understand the fundamental safety protocols and potential hazards to be mindful of when working with electrical systems. Understanding the pathways electricity takes is vital. Circuit Analysis will provide learners with knowledge about how circuits function, the different components within them, and the importance of each in a fully functional system. Ever wondered about the motors that power so many of our daily appliances? The section on Electric Motors demystifies this by breaking down their functioning, types, and applications. Simultaneously, the Electrical Power Distribution Systems module introduces learners to the intricate systems in place to deliver electricity from its source to our homes and businesses. The distinction between AC and DC Circuits is foundational to anyone in the electrical field. This course ensures a thorough grasp of both, detailing their individual characteristics, benefits, and applications. Transformers and Capacitors play pivotal roles in the world of electricity. This section of the Basic Electricity Diploma discusses their functionality, importance, and the fundamental physics behind them. With the fast-paced technological advancements, Electrical Control Systems have become more sophisticated and intricate. This module covers the basics of these systems, offering insight into their operation and real-world application. No course on electricity would be complete without discussing the various Electrical Machines and Devices. This module provides an introduction to the most common machines and devices, from generators to common household appliances, shedding light on their workings. Adhering to the right guidelines is paramount. The Electrical Code and Standards module enlightens learners about the critical standards, both national and international, ensuring that all electrical work aligns with the highest levels of safety and quality. Lastly, the Troubleshooting Electrical Systems unit empowers learners with the skills and knowledge to diagnose and rectify common electrical issues, making them an invaluable asset in any electrical role. To sum it up, the Basic Electricity Diploma is a comprehensive online course designed to provide a robust foundation in electricity. From fundamental safety protocols to advanced topics like troubleshooting, this course covers it all, making it a must-have for anyone eager to embark on or advance their journey in the electrical domain. Equip yourself with the knowledge you need and take your electrical understanding to the next level. Register today! What you will learn 1:Electrical Safety 2:Circuit Analysis 3:Electric Motors 4:Electrical Power Distribution Systems 5:AC and DC Circuits 6:Transformers and Capacitors 7:Electrical Control Systems 8:Electrical Machines and Devices 9:Electrical Code and Standards 10:Troubleshooting Electrical Systems Course Outcomes After completing the course, you will receive a diploma certificate and an academic transcript from Elearn college. Assessment Each unit concludes with a multiple-choice examination. This exercise will help you recall the major aspects covered in the unit and help you ensure that you have not missed anything important in the unit. The results are readily available, which will help you see your mistakes and look at the topic once again. If the result is satisfactory, it is a green light for you to proceed to the next chapter. Accreditation Elearn College is a registered Ed-tech company under the UK Register of Learning( Ref No:10062668). After completing a course, you will be able to download the certificate and the transcript of the course from the website. For the learners who require a hard copy of the certificate and transcript, we will post it for them for an additional charge.

SCULPTING GEL COURSE

By Majestic Academy

Hard gel nail extension course is the most comprehensive UV gel extension course available in London. Our unique course structure and great teaching skills will help you to learn everything quickly and efficiently, all techniques are learnt in "hands-on" practical way. This course is a perfect balance of theory, demonstrations, and practice. Generation X - Sculpting Gels are specially formulated gels that complement a uniquely developed training Gel is one of the basic techniques in the world of professional nail enhancements, it is easier to apply than Acrylic and odour free. The product hardens in LED lamp and for that reason it gives you more time for creating a beautiful design, making it the ideal system for beginners. THE REQUIREMENTS Salon attire must be worn during the course. Student must have clean nail without enhancements and long hair tied back. To ensure maximum practice, students will be required to work on each other throughout the day or on own hands. To attend this course must you have diploma for manicure or Gel polish course. Model for the day 3 THE CONTENT Safety & hygiene Client consultation Record keeping Importance of sanitising and sterilising Aftercare advice How to organise a workspace Technical structure of a nail’s enhancement Troubleshooting gel Correct shape of extended nail Correct White & Pink application Troubleshooting gel Rules on nail design In-fills and removal Advice on products & suppliers Portfolio building process Getting models for practice Charges and loyalty schemes for clients Marketing advice, website, and brand building Organising advertising events Tool and Product introduction Clear overlay – practice on tip & hand Pink & White – practice on tip & hand Application of UV gel set of nails using sculpting technique Form& tips on real hands. Day 3 The 3rd day is a practice and exam day which you will book at the end of day 2. Price Include N2- David Collection Generation X - Sculpting Gels . Upon successful completion an course certificate will be awarded

Industrial Instrumentation and Modern Control Systems

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 5 full-day course provide a comprehensive understanding of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, HART protocol, control valves, actuators, and smart technology. This course will focus on maximizing the efficiency, reliability, and longevity of these systems and equipment by providing an understanding of the characteristics, selection criteria, common problems and repair techniques, preventive and predictive maintenance. This course is a MUST for anyone who is involved in the selection, applications, or maintenance of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology because it covers how these systems and equipment operate, the latest maintenance techniques, and provides guidelines and rules that ensure their successful operation. In addition, this course will cover in detail the basic design, operating characteristics, specification, selection criteria, advanced fault detection techniques, critical components and all preventive and predictive maintenance methods in order to increase the reliability of these systems andequipment and reduce their operation and maintenance cost This course will provide the following information for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology: Basic Design Specification Selection Criteria Sizing Calculations Enclosures and Sealing Arrangements Codes and Standards Common Operational Problems All Diagnostics, Troubleshooting, Testing, and Maintenance Practical applications of smart instrumentation, SCADA, and Distributed Control Systems, control valves, actuators, etc in the following industries will be discussed in detail: Chemical and petrochemical Power generation Pulp and paper Aerospace Water and sewage treatment Electrical power grids Environmental monitoring and control systems Pharmaceutical plants Training Objectives Equipment Operation: Gain a thorough understanding of the operating characteristics of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Diagnostics and Inspection: Learn in detail all the diagnostic techniques and inspections required of critical components of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Testing: Understand thoroughly all the tests required for the various types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Maintenance and Troubleshooting: Determine all the maintenance and troubleshooting activities required to minimize the downtime and operating cost of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Repair and Refurbishment: Gain a detailed understanding of the various methods used to repair and refurbish modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Efficiency, Reliability, and Longevity: Learn the various methods used to maximize the efficiency, reliability, and longevity of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Sizing: Gain a detailed understanding of all the calculations and sizing techniques used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Design Features: Understand all the design features that improve the efficiency and reliability of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Selection: Learn how to select modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology by using the performance characteristics and selection criteria that you will learn in this course Equipment Enclosures and Sealing Methods Learn about the various types of enclosures and sealing arrangements used for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Commissioning: Understand all the commissioning requirements for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Codes and Standards: Learn all the codes and standards applicable for modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Equipment Causes and Modes of Failure: Understand the causes and modes of failure of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology System Design: Learn all the requirements for designing different types of modern control systems, digital control, distributed control systems (DCSs), supervisory control and data acquisition (SCADA) systems, industrial instrumentation, control valves, actuators, and smart technology Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: Industrial Instrumentation and Modern Control Systems Practical Manual (400 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

HVAC, Electric Circuits & Intelligent Electrical Engineering - 8 Courses Bundle

By NextGen Learning

Do you want to learn the essential skills to become a successful HVAC technician? If so, then the HVAC, Electric Circuits & Intelligent Electrical Engineering bundle is for you! This comprehensive bundle includes 8 courses that will teach you everything you need to know about heating, ventilation, and air conditioning (HVAC) systems. The courses in this HVAC, Electric Circuits & Intelligent Electrical Engineering bundle cover a wide range of topics, including: The basics of HVAC systems How to install, maintain, and repair HVAC systems Electrical safety and troubleshooting Refrigeration and heat pump systems Portable appliance testing (PAT) Digital electric circuits and intelligent electrical devices Electrical 3-phase power transformers Heat exchangers High voltage generation for electrical engineering Energy saving in electric motors By the end of this bundle, you will be a qualified HVAC technician with the skills and knowledge to succeed in this rewarding career. Don't miss out on this opportunity to learn the essential skills to become a successful HVAC technician! Click the 'buy' button to learn more about the HVAC, Electric Circuits & Intelligent Electrical Engineering bundle today! Want to know and get familiar with the eight comprehensive courses? Here they are in the following: Course 1: Heating Ventilation and AirConditioning (HVAC) Technician Course 2: Portable Appliance Testing (PAT) Course 3: Digital Electric Circuits & Intelligent Electrical Devices Course 4: Electrical 3 Phase Power Transformers Fundamentals Course 5: Heat Exchanger Course 6: High Voltage Generation for Electrical Engineering Course 7: Energy Saving in Electric Motors Course 8: Electronic & Electrical Devices Maintenance & Troubleshooting From the comfort of our homes to the efficiency of industries, HVAC plays a paramount role. Our course on Heating Ventilation and AirConditioning (HVAC) Technician is designed to provide a theoretical overview of these integral systems. Delve into the realm of Portable Appliance Testing (PAT) to comprehend safety assessments of electrical devices. The Digital Electric Circuits & Intelligent Electrical Devices course illuminates the world of smart electronics and their underlying circuits. The foundation of electricity lies in transformers; learn their essentials with Electrical 3 Phase Power Transformers Fundamentals. Heat Exchanger course unveils the heart of temperature modulation. Explore the electrifying realm of High Voltage Generation for Electrical Engineering, and understand the art of conservation with Energy Saving in Electric Motors. Lastly, master the techniques of maintaining and troubleshooting with Electronic & Electrical Devices Maintenance & Troubleshooting. CPD 80 CPD hours / points Accredited by CPD Quality Standards Who is this course for? Aspiring HVAC technicians aiming to deepen their theoretical knowledge. Engineers seeking to understand electric circuits and energy conservation. Individuals pursuing a foundation in electrical appliance safety and testing. Professionals desiring to learn about high voltage generation. Those enthusiastic about electrical device maintenance and troubleshooting. Career path HVAC Technician - £25K to £35K/year. Electrical Engineer specialising in HVAC - £30K to £50K/year. Maintenance & Troubleshooting Expert - £28K to £40K/year. Electric Circuit Designer - £32K to £47K/year. Power Transformer Specialist - £31K to £48K/year. Energy Conservation Engineer - £29K to £46K/year. High Voltage Electrical Engineer - £33K to £55K/year. Certificates CPD Certificate Of Completion Digital certificate - Included 8 Digital Certificates Are Included With This Bundle CPD Quality Standard Hardcopy Certificate (FREE UK Delivery) Hard copy certificate - £9.99 Hardcopy Transcript: £9.99

CWNA training course description A hands-on course focusing on the technical support of WiFi. Wireless LANs are often seen as simple communications that are simply installed and then left alone to work. This course ensures that delegates will be able to install WiFi networks which work but also enable the delegates to troubleshoot WiFi when it does go wrong. What will you learn Compare 802.11 standards. Configure WiFi networks. Troubleshoot WiFi networks using spectrum analysers, Wireshark and other tools. Implement 802.11 security. Perform RF surveys. CWNA training course details Who will benefit: Technical staff working with WiFi networks. Anyone wishing to pass the CWNA exam. Prerequisites: Intro to data communications & networking Duration 5 days CWNA training course contents Introduction History, standards. RF fundamentals What is RF? Wavelength, Frequency, Amplitude, Phase. Wave behaviour. RF components. Watts, mW, dB, SNR, Link budgets. Hands on Spectrum analysis. Listing WiFi networks. WiFi connection. inSSIDer. Antennas Radiation envelopes, polar charts, gain, Antenna types. Line of Sight, MIMO. Hands on Connecting, installing, changing antennae. RSSI values. 802.11 802.11-2007, 802.11 post 2007, 802.11 drafts. 802.11 b/g/n. Hands on WiFi performance measurement. Spread Spectrum RF frequency bands, FHSS, DSSS, OFDM. Channels. Hands on Configuring channels. Topologies Mesh, Access points, distribution systems, SSID. Hands on AP configuration. Client connection profiles. 802.11 MAC CSMA/CA, Management frames, control frames, data frames. Passive scanning, active scanning. Open system authentication. Shared Key authentication. Association. RTS/CTS. Power management. Hands on Capturing frames, analysing frames. WiFi architecture WiFi client, WLAN architecture: Autonomous, Centralised, distributed. WiFi bridges. WiFi routers. PoE. Hands on WLAN controllers. Troubleshooting RF interference, multipath, adjacent channels, low SNR, mismatched power. Coverage, capacity. 802.11 Security Basics, Legacy security: WEP, MAC filters, SSID cloaking. PSK, 8021.X/EAP, WPA/WPA2. TKIP/ CCMP encryption. Guest WLANs. Wireless attacks, intrusion monitoring. Hands on WEP cracking, WPA2 configuration. RADIUS. RF Site surveys Protocol and spectrum analysis, coverage analysis. Site survey tools. Hands on Performing a site survey.

PVOL350: Solar Training - PV Systems - Tools and Techniques for Operations and Maintenance - Online

By Solar Energy International (SEI)

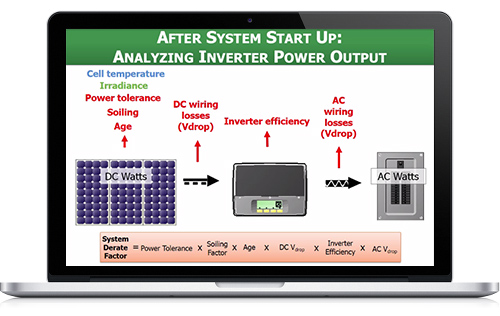

Discuss preventative and reactive maintenance plans and activities. Summarize safety procedures and PPE requirements for O&M technicians. Describe the field procedures required to evaluate the performance of PV systems. List appropriate requirements for meters, tools, and other equipment used in O&M activities. Define the theory, procedures, and processes behind insulation resistance testing, IV curve tracing, infrared cameras and thermal imaging, and other tools of the trade. Analyze test results to determine performance, compare baseline data, and pinpoint system issues. Describe inspection requirements for preventative maintenance inspections. Illustrate methods for locating and troubleshooting common PV array and system faults using appropriate methodologies and testing tools.

24 Hour Flash Deal **33-in-1 Network Administrator Mega Bundle** Network Administrator Enrolment Gifts **FREE PDF Certificate**FREE PDF Transcript ** FREE Exam** FREE Student ID ** Lifetime Access **FREE Enrolment Letter ** Take the initial steps toward a successful long-term career by studying the Network Administrator package online with Studyhub through our online learning platform. The Network Administrator bundle can help you improve your CV, wow potential employers, and differentiate yourself from the mass. This Network Administrator course provides complete 360-degree training on Network Administrator. You'll get not one, not two, not three, but 33 Network Administrator courses included in this course. Plus Studyhub's signature Forever Access is given as always, meaning these Network Administrator courses are yours for as long as you want them once you enrol in this course. This Network Administrator Bundle consists the following career oriented courses: IT Administration and Networking IT Support Technician: Troubleshooting and Technical Expertise CompTIA Network+ Certification (N10-007) Computer Networks Security from Scratch to Advanced Network Security and Risk Management Foundations of IT Security: Protecting Digital Assets Computer Operating System and Troubleshooting Cyber Security Advanced Training Data Center Training Essentials: General Introduction Internet of Things (IoT) SQL Database Management CompTIA Security+ CompTIA Cloud+ (CV0-002) CompTIA PenTest+ (Ethical Hacking) course Web Application Penetration Testing Data Protection and Data Security (GDPR) Training Certification Bash Scripting, Linux and Shell Programming Data Protection (GDPR) Practitioner CompTIA Healthcare IT Technician CompTIA ITF+ (FCO-U61) Information Governance and Data Management Training CEH: Learn Ethical Hacking From A-Z: Beginner To Expert Machine Learning Basics Electronic Device Maintenance and Troubleshooting Course Computer Workstation Safety Training In this exclusive Network Administrator bundle, you really hit the jackpot. Here's what you get: Step by step Network Administrator lessons One to one assistance from Network Administratorprofessionals if you need it Innovative exams to test your knowledge after the Network Administratorcourse 24/7 customer support should you encounter any hiccups Top-class learning portal Unlimited lifetime access to all 33 Network Administrator courses Digital Certificate, Transcript and student ID are all included in the price PDF certificate immediately after passing Original copies of your Network Administrator certificate and transcript on the next working day Easily learn the Network Administrator skills and knowledge you want from the comfort of your home The Network Administrator course has been prepared by focusing largely on Network Administrator career readiness. It has been designed by our Network Administrator specialists in a manner that you will be likely to find yourself head and shoulders above the others. For better learning, one to one assistance will also be provided if it's required by any learners. The Network Administrator Bundle is one of the most prestigious training offered at StudyHub and is highly valued by employers for good reason. This Network Administrator bundle course has been created with 33 premium courses to provide our learners with the best learning experience possible to increase their understanding of their chosen field. This Network Administrator Course, like every one of Study Hub's courses, is meticulously developed and well researched. Every one of the topics is divided into Network Administrator Elementary modules, allowing our students to grasp each lesson quickly. The Network Administrator course is self-paced and can be taken from the comfort of your home, office, or on the go! With our Student ID card you will get discounts on things like music, food, travel and clothes etc. CPD 330 CPD hours / points Accredited by CPD Quality Standards Who is this course for? This Network Administrator training is suitable for - Students Recent graduates Job Seekers Individuals who are already employed in the relevant sectors and wish to enhance their knowledge and expertise in Network Administrator. Requirements To participate in this Network Administrator course, all you need is - A smart device A secure internet connection And a keen interest in Network Administrator. Career path You will be able to kickstart your Network Administrator career because this course includes various courses as a bonus. This Network Administratoris an excellent opportunity for you to learn multiple skills from the convenience of your own home and explore Network Administrator career opportunities. Certificates CPD Accredited Certificate Digital certificate - Included CPD Accredited Hardcopy Certificate - Free Enrolment Letter - Free Student ID Card - Free

Search By Location

- Troubleshooting Courses in London

- Troubleshooting Courses in Birmingham

- Troubleshooting Courses in Glasgow

- Troubleshooting Courses in Liverpool

- Troubleshooting Courses in Bristol

- Troubleshooting Courses in Manchester

- Troubleshooting Courses in Sheffield

- Troubleshooting Courses in Leeds

- Troubleshooting Courses in Edinburgh

- Troubleshooting Courses in Leicester

- Troubleshooting Courses in Coventry

- Troubleshooting Courses in Bradford

- Troubleshooting Courses in Cardiff

- Troubleshooting Courses in Belfast

- Troubleshooting Courses in Nottingham