- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

492 Courses in Nottingham

Advanced Load Forecasting & Methodology

By EnergyEdge - Training for a Sustainable Energy Future

About this Course This 5 full-day course presents the most modern statistical and mathematical forecasting frameworks used by practitioners to tackle the load forecasting problem across short time and long time scales. The course presents practical applications to solving forecasting challenges, supported by real life examples from large control areas. It presents the weather impacts on the load forecasts and the methodologies employed to quantify the weather effect and building a repository of weather normal data. A good load forecast methodology must improve its forecasting accuracy and support a consistent load forecasting process. The load forecasting widely used in the power industry has evolved significantly with the advancement and adoption of Artificial Intelligence techniques such as Machine Learning. With the increased penetration of inverter-based resources, the operation of electric grids grew in complexity, leading to load forecasts that are updated more frequently than once a day. Furthermore, several jurisdictions adopted a smaller granularity than the hourly load forecasts in the effort to reduce the forecasting uncertainties. On the generation side, fuel forecasting professionals must meet energy requirements while making allowance for the uncertainty on both the demand and the supply side. This training course will also feature a guest speaker, who is a Ph.D candidate to provide insights into the most modern aspects of Artificial Intelligence in the context of load forecasting. Training Objectives This course offers a comprehensive approach to all aspects of load forecasting: Gain a perspective of load forecasting from both operators in the generating plant and system operators. Understand and review the advanced load forecasting concepts and forecasting methodologies Learn the application of Artificial Neural Networks and Probabilistic Forecasting methods to manage forecasting uncertainties in short time frames Appreciate market segmentation and econometric framework for long term forecasts Find out the most recent practical application of load forecasting as examples from large power companies Get access to recent industry reports and developments Target Audience Energy load forecasting professionals from power plant and system operators Energy planners and energy outlook forecasters and plant operators Fuel procurement professionals Planners and schedulers of thermal generating units Course Level Intermediate Trainer Your expert course instructor is a Utility Executive with extensive global experience in power system operation and planning, energy markets, enterprise risk and regulatory oversight. She consults on energy markets integrating renewable resources from planning to operation. She led complex projects in operations and conducted long term planning studies to support planning and operational reliability standards. Specializing in Smart Grids, Operational flexibilities, Renewable generation, Reliability, Financial Engineering, Energy Markets and Power System Integration, she was recently engaged by the Inter-American Development Bank/MHI in Guyana. She was the Operations Expert in the regulatory assessment in Oman. She is a registered member of the Professional Engineers of Ontario, Canada. She is also a contributing member to the IEEE Standards Association, WG Blockchain P2418.5. With over 25 years with Ontario Power Generation (Revenue $1.2 Billion CAD, I/S 16 GW), she served as Canadian representative in CIGRE, committee member in NSERC (Natural Sciences and Engineering Research Council of Canada), and Senior Member IEEE and Elsevier since the 90ties. Our key expert chaired international conferences, lectured on several continents, published a book on Reliability and Security of Nuclear Power Plants, contributed to IEEE and PMAPS and published in the Ontario Journal for Public Policy, Canada. She delivered seminars organized by the Power Engineering Society, IEEE plus seminars to power companies worldwide, including Oman, Thailand, Saudi Arabia, Malaysia, Indonesia, Portugal, South Africa, Japan, Romania, and Guyana. Our Key expert delivered over 60 specialized seminars to executives and engineers from Canada, Europe, South and North America, Middle East, South East Asia and Japan. Few examples are: Modern Power System in Digital Utilities - The Energy Commission, Malaysia and utilities in the Middle East, GCCIA, June 2020 Assessment of OETC Control Centre, Oman, December 2019 Demand Side management, Load Forecasting in a Smart Grid, Oman, 2019 Renewable Resources in a Smart Grid (Malaysia, Thailand, Indonesia, GCCIA, Saudi Arabia) The Modern Power System: Impact of the Power Electronics on the Power System The Digital Utility, AI and Blockchain Smart Grid and Reliability of Distribution Systems, Cyme, Montreal, Canada Economic Dispatch in the context of an Energy Market (TNB, Sarawak Energy, Malaysia) Energy Markets, Risk Assessment and Financial Management, PES, IEEE: Chicago, San Francisco, New York, Portugal, South Africa, Japan. Provided training at CEO and CRO level. Enterprise Risk methodology, EDP, Portugal Energy Markets: Saudi Electricity Company, Tenaga National Berhad, Malaysia Reliability Centre Maintenance (South East Asia, Saudi Electricity Company, KSA) EUSN, ENERGY & UTILITIES SECTOR NETWORK, Government of Canada, 2016 Connected+, IOT, Toronto, Canada September 2016 and 2015 Smart Grid, Smart Home HomeConnect, Toronto, Canada November 2014 Wind Power: a Cautionary Tale, Ontario Centre for Public Policy, 2010 POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

APM Project Management Qualification (PMQ): In-House Training

By IIL Europe Ltd

APM Project Management Qualification (PMQ): In-House Training The APM Project Management Qualification (PMQ) (IPMA Level D) is a knowledge-based qualification that allows candidates to demonstrate knowledge of all elements of project management. Candidates will be able to demonstrate an understanding of how these elements interact and how their project fits into their strategic and commercial environment. The course will cover the 67 assessment criteria defined by APM and prepare you to sit the examination on the fifth and final day. In addition to the instructor-led sessions, you should also expect to complete some self-directed study in the evenings. The APM Project Management Qualification (PMQ) examination is a three-hour paper where candidates must answer 10 out of 16 questions that can cover all 67 assessment criteria topics. What you will Learn You'll learn how to: Provide organizations with a proven project management methodology that will allow individuals to plan, organize, and control the successful implementation of projects Achieve the APM Project Management Qualification (PMQ), the UK's leading project management qualification Provide practical skills and techniques to help further your career in project management Getting Started Introductions Course structure Course goals and objectives Overview of the APM Project Management Qualification (PMQ) examination Structure of Organizations and Projects Organization structures Project sponsorship Organization roles Project Office Governance Legislation Project Lifecycle Project Lifecycles Handover and closure Project reviews Situational Context of Projects Project Management Programme Management Portfolio Management The Project Environment Communication Communication Conflict Management Negotiation Leadership and Teamwork Leadership Teamwork Planning for Success Business Case Investment Appraisal Success and Benefits Management Information Management and Reporting Project Management Plan Estimating Earned Value Management Stakeholder Management Scope Management Scope Management Requirements Management Change Control Configuration Management Schedule and Resource Management Schedule Management Resource Management Budgeting and Cost Management Procurement Procurement Contracts Provider Selection and Management Risk Management and Issue Management Risk Management Issue Management Quality Management and Examination Preparation Quality Management Preparation and Examination Preparation and examination briefing APM Project Management Qualification (PMQ) examination

Well Test Analysis in Practice

By EnergyEdge - Training for a Sustainable Energy Future

About this training This 5-day training course enables participants to learn and understand the fundamental concepts of well test analysis. The methodology described in the course, which has become the standard of the industry, presents a systematic way of interpreting well tests in homogeneous and heterogeneous reservoirs, including fissured and multilayered systems. Recommendations for designing tests in such formations, examples, and problem-solving sessions for practical experience and immediate application are included in the course. Training Objectives Upon completion of this course, participants will be able to: Understand the well test analysis methodology Present the straight line, log-log pressure, derivative and deconvolution analysis methods Learn the most common reservoir behaviours and boundary effects Carry out the gas and multiphase analysis Target Audience The course is intended for individuals who involved with the design and interpretation of well tests. The following personnel will benefit from the knowledge shared in this course: Petroleum Production Engineers Production and Wellsite Geologist Geophysicist Reservoir Engineer Drilling Engineer Trainer Your expert course leader has taught numerous well test interpretation industry courses around the world and has been involved in many consulting projects. He is a member of the Society of Petroleum Engineers (SPE) since 1969, and he was elected a Distinguished Member in 2002 and an Honorary Member in 2009. He has chaired or organized many SPE Advanced Technology Workshops. He is a recognized expert in well test analysis and has published over one hundred technical papers and was responsible for many advances in well test interpretation, including: the use of Greens functions; wellbore storage and skin, fractured wells, and wells with double porosity behavior; the first major commercial computer-aided interpretation software; single-well and multi-well deconvolution; and a well test interpretation methodology which has become standard in the oil industry. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Advanced Process Safety Engineering

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Managing process hazards in the hydrocarbon and chemical processing industries is a critical function that requires relevant knowledge and skills due to the risks involved. The Advanced Process Safety Engineering course will discuss the interrelation of the various techniques of process safety for analysing, with a particular emphasis on engineering design aspects, as well as how to manage process hazards in a safe and effective way and how they can potentially be avoided. In this 3 full-day advanced level course, the expert course leader will provide participants with insights and examples from his career and experience to show how their learning should be applied in real-life situations. Feedback and questioning is highly encouraged. Reference material and reports can be provided to give more information on any particular topic of interest. Individual and group exercises, tutored exercises and video case studies will be provided throughout the course to underpin the key learning points. Training Objectives Upon completion of this course, participants will acquire in-depth knowledge of: Risk management and 'As Low as Reasonably Practicable' (ALARP) principles. Different aspects of process design that influence process safety. Approach to 'inherently safer' design. Defence in depth using 'layers of protection'. Process for ensuring the technical integrity of safety-critical equipment. Hazards associated with process materials. Range of hazard identification and consequence modelling techniques. Causes and mitigation of human error. Reliability and availability of safety-critical protection equipment. Role of engineered safety-critical equipment and systems. Target Audience This course is suitable for industry professionals who need to acquire a comprehensive understanding of process safety. This includes those who are required to make managerial decisions where process safety is a key consideration, those who are moving into process safety positions or those who wish to broaden their process safety knowledge within their existing discipline. It is particularly suited for anyone involved in the design, operation, modification or maintenance of a major hazard installation, and will demonstrate a substantial understanding of process safety for those engaged in Continuous Professional Development or aiming for Chartered Engineer status. This course will benefit professionals such as: Operations and maintenance supervisors Process, mechanical and chemical engineers and technicians Design engineers, project engineers and HSE managers Control, automation and instrumentation engineers Course Level Advanced Trainer Your expert course leader has 50 years' experience in chemical and process safety engineering. His early career included 20 years in design and project engineering with various fine chemical and pharmaceutical companies where he designed chemical processes, specified plant equipment and selected materials for highly corrosive and toxic processes, often where textbook data was not available. This was followed by 10 years in offshore oil and gas design projects where he was responsible for setting up a Technical Safety group to change design safety practices in the aftermath of the 1988 Piper Alpha disaster. In recent years, he has been called upon to conduct various offshore and onshore incident investigations. His career has given him experience in project engineering, project management, process design and operations, safety engineering and risk management. He is a Fellow of the UK Institution of Chemical Engineers. He served on the Scottish Branch committee, and was elected chairman for a two-year term in 1991. He has also been chairman of the Safety and Reliability Society - North of Scotland Branch. He has delivered training courses in Process Hazard Analysis (HAZOP and HAZID), Process Safety Management, Hazard Awareness, Risk Assessment, Root Cause Analysis, Failure Modes & Effect Analysis and has lectured on Reliability Analysis to the M.Sc. course in Process Safety and Loss Prevention at Sheffield University. In addition to delivering training courses, he currently facilitates HAZOP / HAZID / LOPA studies and undertakes expert witness roles advising lawyers engaged in contractual disputes, usually involving the design or construction of chemical plants or Oil & Gas production facilities, or criminal prosecutions. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Project Economics, Risk and Decision Analysis for Oil & Gas

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 5 full-day training course looks at the setup of economic analysis cases, including the estimation of recoverable reserves, production profiles, commodity prices, and project costs - CAPEX, OPEX, taxes, royalties, transportation, depreciation, before-tax (BTAX) cash-flow, after-tax (ATAX) cash-flow and international fiscal regimes (production sharing agreement and concessionary system). The course begins from the basic required parameters of inflation, interest and time value of money. These concepts are then transformed into profitability indicators. Last but not the least, the profitability indicators are then used to make investment decisions. The emphasis of this course is to bridge the gap between theoretical concepts and their practical limitations. The participants will be able to appreciate the amount of information that they never thought of. Another emphasis of this course is also on the use of Excel's financial functions. This understanding is very critical when it comes to building economic cash-flow models. Over the years, we have seen that participants really struggle with using the Excel functions correctly and this leads to mistakes that can be easily avoided. In each session, multiple choice problems are provided to participants to reinforce their understanding of the concepts covered in the course. Many quick or tips not widely known, are also shared with the participants. The concepts covered in this course are not restricted to downstream, upstream or petrochemical projects. These concepts can be used to evaluate any type of investment under consideration. Participants will require access to computers/laptops with Excel to solve problems during the course. Training Objectives Upon completion of this course, participants will be able to fully understand the gas market dynamics and Investment Evaluation. They will be able to: Learn how to reduce exposure and mitigate risks in projects by handling uncertainty Clarify concepts such as time value of money, cash-flow models, capital budgeting, IRR, NPV, income producing investments Maximise the return on investments through good decision-making processes based on the commercial viability of projects Improve their decision process, investment and opportunity analysis Acquire the hands-on experience in building their own economic evaluation models and solving case study-based examples Target Audience The following oil & gas company personnel will benefit from the knowledge shared in this course: Facilities and Planning engineers Project and procurement personnel Oil & gas engineers Geologists Financial Analysts Commercial managers Economists Government officials Business advisors Asset managers E&P managers Product and business development personnel Course Level Basic or Foundation Training Methods Organisational Impact Trainer Your expert course leader is a globally recognised subject matter expert in petroleum/project economics and international gas market analysis. He is a recipient of the 2021 Society of Petroleum Engineers (SPE) International Management Award, an award that recognises individuals who make significant technical and professional contributions to the petroleum engineering profession and to the worldwide oil and gas industry. He has 40 years of diversified experience in petroleum engineering, reservoir engineering, project economics and decision analysis. He had been involved in evaluating multi-billion-dollar oil and gas field development, NGL, LNG, GTL, Aluminum smelter, refinery, petrochemical, power and production sharing projects. He has worked with major oil companies such as Saudi Aramco, ZADCO, Qatar Petroleum and companies in USA. He is a registered professional Engineer in the state of Colorado, USA. He is the author of six books: Petroleum Engineering Handbook for the Practicing Engineer, Vol. I and Vol. II, published by PennWell Books, Tulsa, Oklahoma, USA. Project Economics and Decision Analysis, Vol. I and Vol. II, published by PennWell Books, Tulsa, Oklahoma, USA. These books are used as textbooks in universities worldwide to teach petroleum economics to undergraduates and graduate students. Tip & Tricks in Excel based Financial Modeling, Vol. 1 & 2, published by Business Expert Press, New York, USA. He has also authored several papers in the Oil & Gas Journal, The Log Analyst, World Oil, SPE Journals, and Oil & Gas Financial Journal. He has delivered lectures in more than 25 countries around the globe. He has always received excellent feedback, as an expert presenter, from the participants of his courses. Daily daily_agenda POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Carbon Capture, Utilization & Storage (CCUS)

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) This 5 half-day Virtual Instructor Led Training (VILT) course covers carbon capture and geological storage of carbon dioxide. Burning fossil fuels for energy is a major source of carbon dioxide emissions to the atmosphere. Most anthropogenic (man-made) carbon dioxide is emitted by coal-fired or gas-fired power plants, and significant quantities of carbon dioxide are emitted through the production and separation of carbon dioxide-rich natural gas and industries such as cement, iron and steel. Carbon Capture Utilization and Storage, or CCUS, involves the long-term storage of captured carbon dioxide emissions in subsurface geologic formations. This VILT course covers all aspects of CCUS including transport, storage and monitoring, economics and community engagement. It explores in detail the challenges of the current technology of geological storage, monitoring and verification including examples from working projects around the world. Many of these technologies are commonly employed by the petroleum industry. Successful deployment of CCUS will also require economic incentives, appropriate regulation, clarity on liability issues and acceptance by the community. These aspects of CCUS, and the corresponding opportunities for appropriately skilled organisations and individuals also will be discussed. Course Content at a Glance Context for CCS/CCUS as An Emissions-reduction Measure Principles of Geological Storage Finding Geological Storage Sites Stationary Sources of Carbon Dioxide for Capture Carbon Dioxide Capture Technologies Compression and Transport of Carbon Dioxide Economics of CCS/CCUS Community, Safety, Legal & Regulatory Issues Risk Assessment Training Objectives Upon completion of this VILT course, participants will be able to: Identify the need for Carbon Capture and Storage (CCS) Outline the key steps in the Carbon Capture and Storage process Distinguish between reservoir rocks and sealing rocks Describe the importance of permeability and porosity to storing carbon dioxide Contrast the geological structures and trapping mechanisms for storing carbon dioxide Describe the changes in geologically stored carbon dioxide over time Outline the monitoring techniques employed to ensure the carbon dioxide is safely stored Appreciate the industrial applications of carbon dioxide capture Recognize the scale of industry required for transporting and storing carbon dioxide Describe economic considerations for CCS/CCUS Outline the economic and environmental opportunities and challenges with using carbon dioxide injection in a range of applications Explain the challenges of regulatory frameworks and public acceptance in a CCS/CCUS project Identify potential risks of a CCS/CCUS project Outline the risk assessment and management process Target Audience This VILT course is ideally suited for a technical audience - geoscientists, petroleum and chemical engineers - as well as for economists, regulators, legal staff and managers wishing to learn more about the details of both the technical, regulatory and socio-economic aspects of carbon capture and storage. Participants should have: Experience with oil and gas, coal or other energy projects Basic understanding of the energy industry Course Level Intermediate Trainer Your first expert course leader spent 18 years in the Petroleum Industry before joining academia, in both technical and managerial roles with Shell, Arco and Vico. He has received numerous awards, including Distinguished Service, Honorary member and Special Commendation awards from the American Association of Petroleum Geologist (AAPG) and was AAPG's International Vice-President and recently chairman of AAPG's House of Delegates (the Associations Parliamentary body). He is an SPE Distinguished Lecturer (DL) and has served as DL for several other professional organisations, including, AAPG, IPA and PESA. He is currently a Professor of Petroleum Geology and Engineering at the Australian School of Petroleum, University of Adelaide. He holds the South Australia State Chair in Carbon Capture & Storage (CCS) and is also presently Distinguished Scientist of the Cooperative Research Centre for Greenhouse Gas Technologies (CO2CRC), having served earlier as the Storage Program Manager and Chief Scientist. Your second expert course leader has a wide and deep knowledge of major capture technologies: solvent, membrane and adsorption based technologies and has developed pathways for retrofitting CO2 capture and storage (CCS) to fossil fuel-based power plants. He has been actively engaged in Post-combustion capture project management and demonstration projects in Victoria's Latrobe Valley on CO2 capture and hydrogen production, and on CO2 capture using membrane contactor technology. He has led various feasibility studies for the Asian Development Bank on CO2 Capture at Indian Oil Corporation's refineries, for JPOWER on hydrogen production from Victorian brown coal and for Kawasaki on incorporation of CCS in hydrogen production from fossil fuel. He has authored multiple peer reviewed journal articles, co-authored various confidential reports on CO2 capture, utilization and hydrogen production and utility, and has presented his work at various conferences, symposiums and seminars. He has a PhD in Chemical Engineering from Monash University Australia and a Master of Technology in Process Engineering from Indian Institute of Technology Delhi India. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

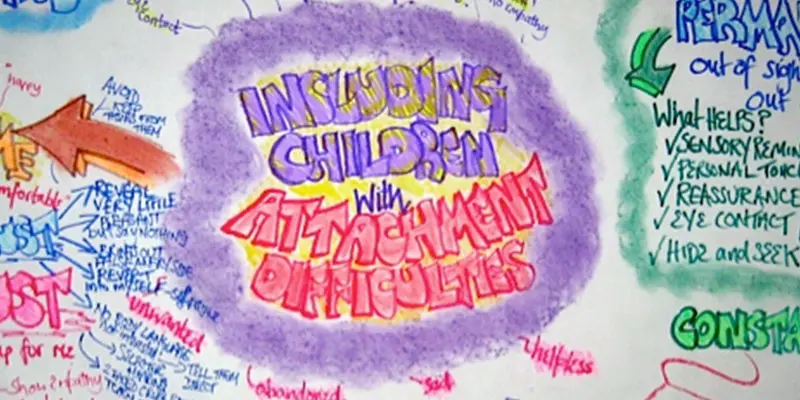

ATTACHMENT DIFFICULTIES: INCLUDING CHILDREN

By Inclusive Solutions

This is a practical ‘non medical’ day for front line practitioners working with children and young people with serious attachment issues arising from loss, trauma and abuse. We look at what Psychology may help us in our understanding of children who have faced issues with love and attachment. Splitting, handling projected feelings, constancy and permanence are explored. Online Course now available via Teachable Platform – Understanding Attachment Learn at your own pace… lots of text and video support Course Category Meeting emotional needs Behaviour and Relationships Inclusion Teaching and Learning Description This is a practical ‘non medical’ day for front line practitioners working with children and young people with serious attachment issues arising from loss, trauma and abuse. Drawing from the international research and literature and our own experience over many years as educational psychologists of the challenges of children with major social and emotional needs, we will explore together what the best practice can and could look like. We explore the language of attachment and outline very practical classroom strategies. We look at what Psychology may help us in our understanding of children who have faced issues with love and attachment. We explore the feelings of being on a desolate island of relational poverty or to imagine swimming with sharks. We explore the themes of violence, anxiety and experience of being a victim as young people grow older. We look at telling lies and explore how we can respectfully understand this. We reveal the new and innovative compass of vulnerability – the cognitive errors to which some are much more vulnerable. We look at triggers, self regulation and unpack a range of strategies. Transference and counter transference are examined along with splitting, handling projected feelings, constancy and permanence. We explore what young people with these difficulties really need from us. We also spend time looking at the emotional impact on practitioners working with children with such needs and what helps at an personal and team level. We can all do something – we do not have to wait for expert therapists to arrive! Testimonials Very moving presentation I will always try and think behind the behaviour now It had a huge impact on all levels We all seem to need it Belonging and feelings are so important Very user friendly Excellent! Learning Objectives Increased confidence regarding developing inclusive practice for children with serious attachment needs in mainstream schools Simple understandable explanation of attachment understood Access to a wider range of practical strategies to impact on social and behavioural needs Deeper understanding of core values surrounding inclusion of emotionally disabled children Opportunity to reflect on professional attitudes and behaviour towards parents and pupils with complex emotional needs New skills, scripts and processes to make inclusion successful Who Is It For ? Practitioners working in schools and other settings with children and young people of all ages Key workers Teaching Assistants with support roles Heads and deputies SENCOs Advanced skills teachers Primary and secondary classroom teachers Parents Local authority support services Course Content The course explores the questions : How can we start to develop an understanding of children with attachment needs? What is the true impact of loss, trauma and abuse? What else can we do to go about including high profile children or young people with challenging emotional needs? What useful psychological constructs can we use to guide us? This course also explores practical strategies and language for key adults rebuilding relationships with individual pupils. This is a participative day that aims to be explorative and practical. Opportunities to develop empathy with the children of concern will be created.

CompTIA A+ bootcamp training course description This course includes A+ Certification: Systems Hardware and Networking Support Skills and A+ Certification: Operating Systems and Security Support Skills. The course will provide IT "super users" or new support professionals with the fastest route to A+ Certification. Full practical sessions will prepare students for the two A+ Certification exams. Note: Some self-study each evening will be required. What will you learn Install, configure, and troubleshoot peripheral devices, system components, print devices, wired and wireless LAN links and internet access devices. Install, configure, and troubleshoot the Microsoft Windows, Linux, and Mac OS PC operating systems plus iOS, Android, and Windows mobile devices. Perform basic PC maintenance. Configure access control measures. Perform basic PC maintenance. CompTIA A+ bootcamp training course details Who will benefit: Students wishing to take both CompTIA A+ exams. Prerequisites: PC fundamentals Duration 5 days Networking Microsoft Systems course contents Peripherals and Adapters Motherboard Components, Connection Interfaces, Display Devices, Audio and Multimedia Devices, Removable Storage Devices. System Components Mass Storage Devices, System Memory, Processors, BIOS and UEFI, Power Supplies. Troubleshooting and Mobile Devices Troubleshooting System Components, Laptops, Mobile Devices, Troubleshooting Mobile Devices. Printer and Network Hardware Printers, Configuring Printers, Troubleshooting Printers, Network Architectures, Ethernet Networks. Networks Wireless Networks, Internet Connections, Internet Protocol, Routers and Firewalls, Troubleshooting Networks. Supporting Windows (1) Windows Operating System, Administration Tools, Managing Storage, Managing Files, Managing Applications. Supporting Windows (2) Managing Devices, Managing Performance, Troubleshooting Windows, Installing Windows. Supporting Windows Troubleshooting Boot Problems, Maintenance and Backup, Threats and Vulnerabilities, Viruses and Malware, Securing Workstations, Securing Data. Supporting Windows Networks Configuring Network Connections, Securing Network Connections, Configuring Shared Resources, Virtualization and Services. Linux, OS X, and Mobile OS Linux Operating System, OS X, Mobile Operating Systems, Mobile OS Security and Troubleshooting, Safety and Environmental Procedures, Professionalism and Communication.

Effective Leadership Development

By Leadership Management International (LMI) UK

Everyone has what it takes to become an effective leader, but first you must learn the skills needed to succeed in a position of responsibility. Our program will help people nurture the talent within and allow managers to lead confidently. Sometimes, working longer hours isn’t the right approach, as you risk burning out and abandoning the task at hand. Instead, effective leadership teaches you how to organise your workload, practice better time management and learn the power of delegation.

Best Practice in Portfolio Management in Upstream Oil and Gas

By EnergyEdge - Training for a Sustainable Energy Future

About this Virtual Instructor Led Training (VILT) This 4 half-day Virtual Instructor Led Training (VILT) course presents the principles and best practices of portfolio management in the upstream (E&P) oil and gas industry. The VILT course is equally valuable for small independents, large integrated international companies and national oil companies. The VILT course consists of presentations, case studies, illustrative practical exercises and syndicate discussions. Particular emphasis is given to pragmatic portfolio management approaches and solutions which can be implemented swiftly without recourse to major investments in planning and portfolio management software. The VILT course will draw on examples from your expert course leader's 35+ years' experience in the oil and gas industry as an explorationist, upstream vice-president and management consultant. The VILT course handout will comprise softcopy slides used in the presentation and a softcopy workbook for the exercises. Participants will gain proficiency in portfolio management techniques, understand how and why to undertake this activity and be able to apply key concepts directly in the business of their teams / divisions. The VILT course will be presented over 4 half-days, using Microsoft Teams or Zoom and a proprietary set of VILT tools. Participants will be asked to complete a pre course questionnaire (PCQ) addressing their objectives and experience, and attend a session to familiarise themselves with VILT tools before course commencement. Training Objectives To present the tools, concepts and principles of portfolio management To define the quantitative metrics which are used to describe projects in a portfolio To understand the benefits of portfolio management at different stages of the upstream business: in strategy development, opportunity screening, business development, drilling prospects, conducting appraisal of discoveries and developing fields To put portfolio management in the organisational context by describing the role of the portfolio management team and examining how value assurance (quality control) is best conducted on portfolio data for projects and assets To demonstrate how portfolio management contributes to improved business performance By the end of the VILT course, participants will understand: Key concepts and principles of portfolio management How to design a simple portfolio database and describe complex projects in a small number of objective metrics How to segment the portfolio into meaningful units How to use portfolio data in making business choices and decisions at the strategic and tactical levels The extent to which it is meaningful and reasonable to make comparisons across different portfolio segments How the portfolio management team can support the wider business in decision-making Target Audience This VILT course is specially designed for exploration and development geoscientists, E&P economists and finance staff, and E&P managers. Both technical and non-technical staff will benefit from the concepts presented. Companies are encouraged to send participants from different functions and seniority levels to gain great benefits especially those which would like to implement the concepts presented in this VILT course. Course Level Basic or Foundation Training Methods The VILT course will be delivered online in 4 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. The VILT course will be presented in an interactive workshop format that allows for discussion. Course Duration: 4 half-day sessions, 4 hours per session (16 hours in total). Trainer Your expert course leader draws on more than 35 years of experience managing, reviewing and directing projects in all aspects of the exploration business: from exploration business development (new ventures), through prospect maturation and drilling, to the appraisal of discoveries. He has more than 30 years' experience with Shell International, followed by 10 years consulting to NOCs in Asia Pacific, Africa and South America and independent oil companies in the United Kingdom, continental Europe and North America. Other than delivering industry training, he has worked on projects for oil & gas companies of all sizes, including independents, national oil companies and (super)-majors, private equity firms, hedge funds and investment banks, and leading management consulting firms. He is an alumnus of Cambridge University. He has M.A and Ph.D. degrees in geology and is a Fellow of the Geological Society of London as well as a respected speaker on management panels at international conferences. Professional Experience Management consultancy & executive education: Advice to investment banks, businesses and major consulting firms. Specialist expertise in upstream oil & gas, with in depth experience in exploration strategy, portfolio valuation and risk assessment. Leadership: Managed and led teams and departments ranging from 3 - 60 in size. Provided technical leadership to a cadre of 800 explorationists in Shell worldwide. Member of the 12-person VP team leading global exploration in Shell, a $3 bln p.a. business and recognised as the most effective and successful among its industry peers. Accountability & decision-making: Accountable for bottom-line results: in a range of successful exploration ventures with budgets ranging from $10's million to $100's million. Made, or contributed to, complex business decisions / investments, taking into account strategic, technical, commercial, organisational and political considerations. Corporate governance: Served as non-executive director on the Boards of the South Rub al Khali Company (oversight of gas exploration studies and drilling in Saudi Arabia) and SEAPOS B.V. (exploration deep-water drilling and facilities management). Technical & operations: Skilled in exploration opportunity evaluation, the technical de risking of prospects, portfolio analysis and managing the interface between exploration and well engineering activities. Unparalleled knowledge of the oil and gas basins of the world, and of different operating regimes and contractual structures, ranging from Alaska, Gulf of Mexico and Brazil, through to the Middle East, former Soviet Union, Far East and Australia. Safety: Following an unsatisfactory audit, became accountable for safety performance in Shell's exploration new ventures. Through personal advocacy and leadership of a small team, delivered pragmatic and effective HSE systems, tools and staff training / engagement and a dramatically improved safety record. R&D: Experience in the 3 key roles in R&D: scientific researcher, research manager, and 'customer' for R&D products. After re-defining Shell's exploration R&D strategy, led the re-structuring of the R&D organization, its interface with 'the business' and approaches to deployment and commercialization. Strategy: Accomplished at formulating competitive strategies in business, R&D and technology deployment, translating them into actionable tactics and results. Defined the exploration strategy of PDO (a Shell subsidiary in Oman) and latterly of Shell's global exploration programme. Professional education, behavioural/motivational coaching: Experienced in organisational re-design, change management, leadership education and talent development. Commercial skills: Personally negotiated drilling compensation claims, educational contracts and E&P contracts, with values of $5 million to $100+ million. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

Search By Location

- exam Courses in London

- exam Courses in Birmingham

- exam Courses in Glasgow

- exam Courses in Liverpool

- exam Courses in Bristol

- exam Courses in Manchester

- exam Courses in Sheffield

- exam Courses in Leeds

- exam Courses in Edinburgh

- exam Courses in Leicester

- exam Courses in Coventry

- exam Courses in Bradford

- exam Courses in Cardiff

- exam Courses in Belfast

- exam Courses in Nottingham