- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Telecomms training course description A comprehensive tour of the telecommunications technologies and terminology currently in use, and under development. What will you learn List and describe components of the PSTN. Explain how calls are made over the PSTN Compare analog and digital transmission methods. Describe the technologies within the transport plane. Recognise the benefits of extra features available in today's telephone networks. Telecomms training course details Who will benefit: Anyone new to the Telecommunications industry. Prerequisites: None. Duration 2 days Telecomms training course contents Telephone network architecture Handsets, local loop, distribution points, Local exchanges, main telephone switches, PBXs. Making a call - some basics Telephone call components, how a telephone call works, accessing the local exchange, loop disconnect, DTMF, standards, E.164, PSTN routing, Intelligent Networks, Special Rate Services. Analogue vs Digital Voice characteristics, PSTN bandwidth, analogue signalling, Digital encoding, PCM and the 64k, ADPCM and other voice compression methods. PBXs PABX, Call processing, networking PBXs, PBX facilities, bandwidth, blocking probability and Erlangs, Erlang models, using Erlang tables. Transmission methods Two wire transmission, 64k circuits, Nx64, E1, 2 wire to 4 wire conversion, echo, echo suppression, echo cancellers, twisted pair, coax, fibre optic, power lines, satellite systems, microwave. Signalling Analogue signalling, loop start, earth calling, E&M, AC15. Digital signalling -CAS, robbed bits and E1 slot 16 signalling. Digital signalling CCS, Q.931, SS7, Q.SIG, DPNSS, DASS2. Transport planes PDH, PDH issues, SDH, SDH architecture, SDH standards, SDH bit rates, SDH mulitplexors, DWDM. Networks Circuit Switched Networks, TDM, Packet Switched Networks, Frame Relay, Message Switching, Circuit Switching, STDM, Cell Switching, ATM, ATM cells, ATM traffic parameters, ATM QoS, MPLS. Other network access Modems, modulation, speeds, ISDN, BRI, PRI, xDSL, SDSL, ADSL. Other Services Centrex, VPNs, FeatureNet, CTI, Call Processing Systems, Voice Mail, Automated Attendant Systems, Interactive Voice Response, Call Management Systems, Call Conferencing, Star Services. Mobile communications 3 types of wireless telephone, mobile generations, base stations, cells, GSM, GPRS, 3G, UMTS, WCDMA, 4G, LTE. VoIP overview What is VoIP, VoIP benefits, What is IP? The IP header, Packetising voice, VoIP addressing, H.323, SIP, RTP. Bandwidth requirements.

Decision Making and Problem Solving (In-Person)

By IIL Europe Ltd

Decision Making and Problem Solving (In-Person) We may live in an era of fast technology and increasing reliance upon automation, but our human abilities to think critically, make careful decisions, and solve nuanced problems are more important than ever. Our personal lives depend on those things, and so do the lives of our organizations. Since business is now conducted at remarkable speeds, we put our organizations at great risk daily when we have weak competencies with decision-making and problem-solving. Decisions and solutions that are executed impulsively and without structured approaches can create more problems or make existing ones worse! This course aims to help participants improve their skills so they can execute well and add value to the workplace. Learners will experience multiple decision-making and problem-solving models, tools, and techniques meant for the real world. They will learn how to align their growing toolboxes with the right situational contexts so that they can transfer that skill to the workplace. They will also discover how indecision, cognitive bias, and default thought processes can create obstacles to effective decision-making and problem-solving. What you will Learn Recognize the importance of making a sound decision in a timely manner Infer types of cognitive biases and obstacles that impact decision-making Separate facts, requirements, ideas, and perceptions when making a decision or solving problems Apply structured decision-making and problem-solving approaches Conduct cause and effect and Force Field analyses Evaluate alternative solution methods using various techniques Analyze real world situations to determine the best aligned decision-making and problem-solving models, tools, and techniques Implement decision-making and problem-solving models, tools, and techniques Getting Started Foundation Concepts Contextualizing decisiveness and problem-solving Discriminating between decisiveness and problem-solving Understanding Decision-Making Decision-making challenges and impacts Key drivers of good decision-making Thought processes and obstacles Knowledge, skills, and abilities (KSAs) Decision-Making Models and Supporting Tools Decision-making models, tools, and guidelines Tools to evaluate alternatives Translating requirements into action Problem-Solving Defining the problem Problem-solving models Cause and effect analysis Quick hit vs. innovative problem-solving Summary and Next Steps Course summary Personal action plan

Decision Making and Problem Solving: In-House Training

By IIL Europe Ltd

Decision Making and Problem Solving: In-House Training We may live in an era of fast technology and increasing reliance upon automation, but our human abilities to think critically, make careful decisions, and solve nuanced problems are more important than ever. Our personal lives depend on those things, and so do the lives of our organizations. Since business is now conducted at remarkable speeds, we put our organizations at great risk daily when we have weak competencies with decision-making and problem-solving. Decisions and solutions that are executed impulsively and without structured approaches can create more problems or make existing ones worse! This course aims to help participants improve their skills so they can execute well and add value to the workplace. Learners will experience multiple decision-making and problem-solving models, tools, and techniques meant for the real world. They will learn how to align their growing toolboxes with the right situational contexts so that they can transfer that skill to the workplace. They will also discover how indecision, cognitive bias, and default thought processes can create obstacles to effective decision-making and problem-solving. What you will Learn Recognize the importance of making a sound decision in a timely manner Infer types of cognitive biases and obstacles that impact decision-making Separate facts, requirements, ideas, and perceptions when making a decision or solving problems Apply structured decision-making and problem-solving approaches Conduct cause and effect and Force Field analyses Evaluate alternative solution methods using various techniques Analyze real world situations to determine the best aligned decision-making and problem-solving models, tools, and techniques Implement decision-making and problem-solving models, tools, and techniques Foundation Concepts Contextualizing decisiveness and problem-solving Discriminating between decisiveness and problem-solving Understanding Decision-Making Decision-making challenges and impacts Key drivers of good decision-making Thought processes and obstacles Knowledge, skills, and abilities (KSAs) Decision-Making Models and Supporting Tools Decision-making models, tools, and guidelines Tools to evaluate alternatives Translating requirements into action Problem-Solving Defining the problem Problem-solving models Cause and effect analysis Quick hit vs. innovative problem-solving Summary and Next Steps Course summary Personal action plan

WiFi demystified training course description A concise overview aimed at less technical staff requiring an overview of WiFi networks. The course covers the technologies at a high level allowing delegates to discuss WiFi networks with others recognising the buzzwords used. The course will also allow the delegates to recognise the issues involved in planning and installing WiFi networks as well as securing them. What will you learn Recognise the different WiFi technologies available. Describe the architecture of WiFi networks including the role of Access Points. Recognise the distance limitations of WiFi networks. Describe the buzzwords used in WiFi. Recognise the security issues of WiFi networks. WiFi demystified training course details Who will benefit: Anyone working with WiFi networks. Prerequisites: None. Duration 1 day WiFi demystified training course contents Introduction When to use wireless, when to use wired, WiFi technologies: 802.11, 802.11a, 802.11b, 802.11g, 802.11n, WiFi speeds and distances, comparison to other wireless technologies, 802.15 (Bluetooth), 802.16 (WiMax). Simple WiFi networks Network cards, Antennae, Access Points, WiFi routers. Enterprise WiFi networks SSIDs, Multiple WiFi networks, Repeaters, Wireless bridges, Controller based access points, Wireless switches, Power Over Ethernet. RF site surveys Steps and techniques, tools, analysing the feasibility of WiFi, range, performance, roaming. Security How safe are WiFi networks? Encryption, Authentication, WEP WPA WPA2. 802.1x, EAP, RADIUS.

LAN training course description A concise overview course covering Local Area Networks with particular emphasis on the use of Ethernet and Wireless LANS. As well as explaining buzzwords we cover how the technology works at a simple level. After defining LANs the course moves onto Ethernet and switching also covering VLANs. WiFi is then covered, with coverage of 802.11 standards and frequencies along with integrating WiFi with Ethernet. The course then covers routers and their role in connecting networks and the course finishes with a comparison of Ethernet vs WiFi and when to use them. What will you learn Describe how Ethernet works (in simple terms) and when to use Ethernet. Explain the difference between a switch and a router. Describe how WiFi works (in simple terms). Describe the role of Access points. Evaluate wireless technologies and when to use them. List the speeds of various LAN technologies. LAN training course details Who will benefit: Sales staff, managers and other non technical staff. Prerequisites: None. Duration 1 day LAN training course contents LANS What is a LAN? LAN standards, LAN choices, choosing the media, copper, UTP, cat5e, fibre, RF, bandwidth speeds, link aggregation, Full/half duplex. Ethernet What is Ethernet? 802.3, parts of Ethernet, Ethernet evolution, MAC addresses, frames, broadcasts. Ethernet switches What are switches, switches versus hubs, how switches work, ways to configure switches, Loops, STP. VLANs What are VLANs? Why have VLANs, impact of VLANs, Tagging (aka trunking), 802.1Q Wireless LANS Type of wireless LAN, RF frequencies, 2.4GHz, 5GHz, others, interference, standards, 802.11 and variants, CSMA/CA. Wireless LANS NICs, Access points, integration with Ethernet, multiple access points, mesh networks, WiFi security. Interconnecting LANs Routers, connecting networks, interconnecting VLANs, IP addressing, Layer 3 switches. Summary WiFi vs Ethernet.

WANs training course description A concise overview course covering Wide Area Networks with particular emphasis on the WAN options available including the use of the Internet. What will you learn Choose and evaluate WAN technologies. Recognise the role of service providers. Describe the benefits of VPNs. Describe how the Internet can be used as a WAN. Describe the equipment needed to connect LANS to WANS. List the speeds of various WAN technologies. WANs training course details Who will benefit: Anyone, although the course is particularly aimed at non-technical personnel needing some knowledge of WANS. Prerequisites: Network fundamentals Duration 1 day WANs training course contents WANS WAN architecture, Common WAN terms, Core vs access, service providers, relationship with 7 layer model, WAN equipment, how to choose a WAN. Layer 1 Copper, phone lines, fibre, coaxial, satellite, wireless. Cabling to the building, CPE cabling, interfaces. Layer 2 Dial up vs. Dedicated vs. packet switched networks and when to use them. Packet switching vs. circuit switching. Point to point and point to multipoint. Dialup access technologies Modems, ISDN, BRI, PRI. Access with dedicated lines XDSL, leased lines. WAN services X.25, SMDS, Frame Relay, CIR, ATM, Internet, MANS, dark fibre and other services. Case study: Selecting WAN technologies. Service provider technologies MPLS, SDH, WDM, DWDM. Routers Network addressing, default gateways, routing tables, routing protocols. Internet architecture Service providers, ISPs, private peering, public peering, core WANs in the Internet. VPNs Private networks, public networks, What are VPNs?, benefits of VPNs, tunnelling, encryption, IPSec. Case study: Specifying WAN connectivity.

Tableau Desktop Training - Foundation

By Tableau Training Uk

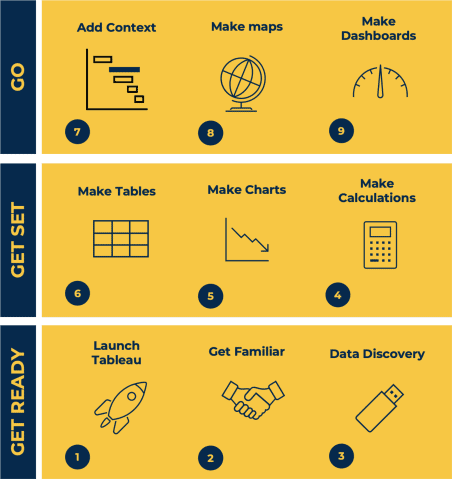

This Tableau Desktop Training course is a jumpstart to getting report writers and analysts with little or no previous knowledge to being productive. It covers everything from connecting to data, through to creating interactive dashboards with a range of visualisations in two days of your time. For Private options, online or in-person, please send us details of your requirements: This Tableau Desktop Training course is a jumpstart to getting report writers and analysts with little or no previous knowledge to being productive. It covers everything from connecting to data, through to creating interactive dashboards with a range of visualisations in two days of your time. Having a quick turnaround from starting to use Tableau, to getting real, actionable insights means that you get a swift return on your investment of time and money. This accelerated approach is key to getting engagement from within your organisation so everyone can immediately see and feel the impact of the data and insights you create. This course is aimed at someone who has not used Tableau in earnest and may be in a functional role, eg. in sales, marketing, finance, operations, business intelligence etc. The course is split into 3 phases and 9 modules: PHASE 1: GET READY MODULE 1: LAUNCH TABLEAU Check Install & Setup Why is Visual Analytics Important MODULE 2: GET FAMILIAR What is possible How does Tableau deal with data Know your way around How do we format charts Dashboard Basics – My First Dashboard MODULE 3: DATA DISCOVERY Connecting to and setting up data in Tableau How Do I Explore my Data – Filters & Sorting How Do I Structure my Data – Groups & Hierarchies, Visual Groups How Tableau Deals with Dates – Using Discrete and Continuous Dates, Custom Dates Phase 2: GET SET MODULE 4: MAKE CALCULATIONS How Do I Create Calculated Fields & Why MODULE 5: MAKE CHARTS Charts that Compare Multiple Measures – Measure Names and Measure Values, Shared Axis Charts, Dual Axis Charts, Scatter Plots Showing Relational & Proportional Data – Pie Charts, Donut Charts, Tree Maps MODULE 6: MAKE TABLES Creating Tables – Creating Tables, Highlight Tables, Heat Maps Phase 3: GO MODULE 7: ADD CONTEXT Reference Lines and Bands MODULE 8: MAKE MAPS Answering Spatial Questions – Mapping, Creating a Choropleth (Filled) Map MODULE 9: MAKE DASHBOARDS Using the Dashboard Interface Dashboard Actions This training course includes over 25 hands-on exercises and quizzes to help participants “learn by doing” and to assist group discussions around real-life use cases. Each attendee receives a login to our extensive training portal which covers the theory, practical applications and use cases, exercises, solutions and quizzes in both written and video format. Students must use their own laptop with an active version of Tableau Desktop 2018.2 (or later) pre-installed. What People Are Saying About This Course “Excellent Trainer – knows his stuff, has done it all in the real world, not just the class room.”Richard L., Intelliflo “Tableau is a complicated and powerful tool. After taking this course, I am confident in what I can do, and how it can help improve my work.”Trevor B., Morrison Utility Services “I would highly recommend this course for Tableau beginners, really easy to follow and keep up with as you are hands on during the course. Trainer really helpful too.”Chelsey H., QVC “He is a natural trainer, patient and very good at explaining in simple terms. He has an excellent knowledge base of the system and an obvious enthusiasm for Tableau, data analysis and the best way to convey results. We had been having difficulties in the business in building financial reports from a data cube and he had solutions for these which have proved to be very useful.”Matthew H., ISS Group

Meet and Greet: LSN & LSOC x Barts & the London Surgical Society x Barts & London CardioSoc

5.0(12)By London School of Cardiothoracics

🚨 Passionate about Cardiothoracic Surgery? 🚨 Join us for a speed mentoring event where you’ll get a chance to network with the London School of Cardiothoracic (LSOC) faculty, the London Student Network (LSN) team, BLSS, and BLCardiosoc! 🌟 This is a valuable opportunity to network, ask all the questions you can, and learn about upcoming events for the year! 💬🫀✨ ✨ Free food and refreshments ✨ 🗓 Limited slots available — register now before it’s too late! We can’t wait to see you there! 😄

The Therapeutic Power of Language

By Human Givens College

– a psychotherapy skills masterclass The language we use has a huge impact on others – on this practical, inspiring course you will learn how to combine solution-focused techniques and effective language skills to help relieve distress and improve outcomes, as quickly as possible… Accredited CPD Certificate : 12 hours Length 2 days (9:30am - 4:00pm) Excellent course! I’ve learnt so much and been inspired so much. Gareth has a wonderful style of delivery...MARY FLYNN This course is suitable for anyone working with adults, teens or children – the knowledge and skills you will gain have a wide range of applications in addition to therapy and counselling, including coaching, healthcare, teaching, motivation, overcoming resistance, emotional turmoil and much more. You will leave with a powerful toolkit of precisely-targeted and creative therapeutic language skills, as well as a range of effective brief therapy strategies. These can be easily tailored to any individual and used to successfully help people resolve a wide range of conditions and problems as quickly as possible. If you want to be more effective in what you do, these are core skills to have… Denise Winn previously taught this course, it is now delivered by Gareth Hughes Why take this course Language is key to everything we do – being aware of the power of language to help or do harm is essential when we’re trying to help people. Knowing how to use it well can make all the difference to a successful therapeutic outcome. Paying attention to the language we use is central to the human givens approach to therapy and counselling: our choice of words is crucial in building rapport with people, learning more about someone – their unique qualities and abilities – in listening and responding, in providing motivation and in collaborating to agree goals and strategies for the effective resolution of their problems. The careful use of language is essential for other areas of life too: at work, home, with family and friends – and this 2-day course is accessible to all. It can be taken as part of the Human Givens Diploma or as a stand-alone course. You will gain a solid foundation in the most effective brief solution-focused strategies and language skills that are essential if you want to be able to help people as quickly as possible. By distilling the essence of proven brief therapy approaches and working in tune with the givens of human nature, outcomes can be dramatically improved and suffering successfully reduced. You will also learn how any team of professional healthcare workers can safely incorporate brief therapy techniques into their work with patients suffering from depression, anxiety, panic attacks, PTSD, anger, OCD, eating disorders, addiction and relationship/marital/family problems, thereby improving outcomes and reducing suffering on an even wider scale. Good to know This course gives you essential skills that are used in the successful treatment of a wide range of conditions, such as anxiety disorders, depression, addictions, self-harm, OCD and the rewind technique for treating trauma and phobias. They are also fundamental skills to have when using guided imagery and visualisation. This course is an essential component of Part 1 of the HG Diploma. I feel very excited and energised. I can't wait to start using these techniques...OCCUPATIONAL THERAPIST What will you learn The essential skills needed for successful brief therapy New information about the APET™ model – why it is so important to construct therapy that is in tune with our how brains work (our emotional reactions come first) – this speeds up therapy and explains why purely cognitive and behavioural approaches can take so long An ability to get to the root of the matter quickly by establishing which innate needs are not being met and why (the essence of effective brief therapy) Quick rapport building skills How to use the RIGAAR™ structure to improve therapy outcomes Reflective listening and reflective reframing How to use therapeutic language skills directly and indirectly to initiate change Ways to use solution-focused questioning to create a framework for change How to identify and use your client’s own life resources An understanding of why the human givens approach dramatically increases the likelihood of therapy being brief, regardless of the presenting problem A range of psychological interventions to use with common psychiatric problems: anxiety, panic attacks, depression, intrusive thoughts, relationship difficulties and so on Promoting cooperation by developing realistic and achievable goals How to identify exceptions (when the problem doesn’t occur) and get the patient to take credit for them How to generate motivation for change in your patients Separating the patient’s core identity from their problem How to minimise or overcome resistance How not to be drawn in to a client’s negative self-view Great use of case histories to illustrate the skills covered How to use the psychological laws of positive expectancy and concentrated attention An understanding of why taking this collaborative human givens stance, reduces stress and pressure on you Plenty of opportunity to consolidate what you are learning by practising the skills yourself How is the course structured? Held over two consecutive days, this skills-based practical workshop combines a blend of talks, demonstrations and exercises. Each day starts at 9.30pm and finishes at 4.00pm, with 2 breaks for networking and refreshment and 45 minutes for lunch. Course notes, refreshments and lunch are included on both days. Who is this course suitable for? You and your patients will benefit enormously from you attending these two days. If you are a counsellor, psychotherapist, clinical psychologist, mental health nurse, GP, doctor, nurse, OT, physiotherapist, youth worker, social worker, health visitor, support worker or any other caring professional, and wish to be more effective in what you do, this course gives you the perfect opportunity to discover new, subtle but highly effective skills with plenty of time to practise to help you assimilate them into your own work. Many other professions – such as educational and business professionals – also find the skills and information covered highly applicable to and beneficial for their own work. It is also suitable for anyone who is thinking of a career in this field as these are core skills needed for successful brief, solution-focused psychotherapy. This course has been independently accredited by the internationally recognised CPD Standards Office for 12 hours of CPD training. On completion of this training you’ll receive CPD certificates from the College and the CPD Standards Office.

ELECTRIC FILING COURSE

By Majestic Academy

This One -day class teaches the safe and efficient use of electric filing machines. Electric files can add to the overall professionalism of your service and help reduce the strain on hands, arms, and shoulders. The course is suitable for both the inexperienced electric file user and for the experienced technician. THE REQUIREMENTS Salon attire must be worn during the course. Student must have one (right if you work with right hand) hand with clean nail without enhancements and left hand with nail enhancement which have 2-3 weeks growth for infill/backfill and long hair tied back. To ensure maximum practice, students will be required to work on each other throughout the day or on own hands or practice hand. To attend this course must have 3-month experience working with nails enhancement (Gel or Acrylic) Please bring your own acrylic or gel brush and product, cuticle pusher, nippers and if possible, your own Electric File. In case you do not own any of these you can buy them from us. THE CONTENT Health & Safety How the Electric File Works Safe Filing Techniques Speeds required Back-Fill Techniques Electric File Maintenance Finish Filing Different drill bits Cleaning and sanitizing and troubleshooting DURATION This is one day course which runs from 10:30am to 4:00pm PRICE INCLUDES A certificate of attendance. (Kit is not included – (Electric file and nail drill bits,nail file )

Search By Location

- speed Courses in London

- speed Courses in Birmingham

- speed Courses in Glasgow

- speed Courses in Liverpool

- speed Courses in Bristol

- speed Courses in Manchester

- speed Courses in Sheffield

- speed Courses in Leeds

- speed Courses in Edinburgh

- speed Courses in Leicester

- speed Courses in Coventry

- speed Courses in Bradford

- speed Courses in Cardiff

- speed Courses in Belfast

- speed Courses in Nottingham