- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

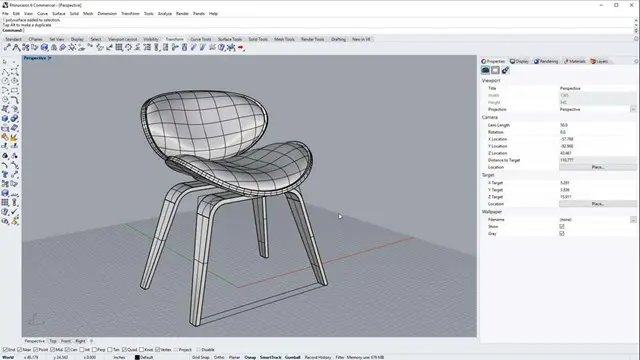

FURNITURE DESIGN TRAINING

By Real Animation Works

Furniture design face to face training customised and bespoke.

Offshore & Marine Supply Base Operations Management - For Servicing International E & P Fleet and Wind Farm Operations

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course The Oil & Gas E&P industry is evolving from deep sea exploration to renewable sources of energy through windfarms and solar fields offshore. In tandem, OSBs will need to evolve for sustainability and revival from stagnant traditional Supply Base Models. The changing role of OSBs is toward support services for decommissioning projects and LNG Floating Terminals. In addition, the new geographical regions of East and South Africa are coming up at a faster pace. All such operations are dependent upon a complex network of transport and supply in order to deliver the staff, materials, machinery, and crew provisions where and when needed. This 3 full-day course is curated to enhance the skills and competencies of passionate professionals to plan and organise resources, minimise turnaround time for the vessels engaged in support of Offshore E & P operations. Various hands-on exercises can equip the participants to implement viable and feasible approaches for safe and efficient management of OSBs in compliance with continuously evolving international best practices and Oil & Gas standards. This course is specially developed for investors, business owners, senior executives and professionals from the offshore & marine logistics industry, with the following objectives: To provide a firm understanding about the role of an Offshore & Marine Supply Base in support of Oil & Gas E & P fleet operations, in contrast with traditional merchant shipping logistics. To provide an in-depth knowledge about the range and diversity of services being offered by Offshore & Marine Supply Bases ('OSB') in the target regions. To equip with the knowledge and information required for taking investment decisions when venturing in Offshore E & P Sector. To introduce contemporary techniques and tools required to identify target customer segments while developing a new OSB or expanding operations of an existing OSB. To elaborate comparative management methodologies for OSB facilities and services management, based on deployment of ICT solutions so as to deliver value added services to the customers. To learn to identify methodologies for sales and distribution of services to the customers and non-paying users of the OSB. To identify relevant state legislation for licensing & governing an OSB, and enforce through contractual obligations, rights and responsibilities of the parties as clients of an OSB. To develop and implement Business Processes with built-in Performance Evaluation Metrics for achieving competitive advantage over the peers in the OSB segment. To develop and implement integrated OSB's Risk Management framework. This course can also be offered through Virtual Instructor Led Training (VILT) format. Training Objectives Upon completion of this course, the participants will be able to: Implement and comply with the QHSSSE regulations and national or Port Controls regime for safe handling of import & export cargo and movements of the vessels. Establish role and responsibilities of the Offshore Supply Base management team. Plan and organise resources so as to minimise turnaround time for the vessels engaged in support of Offshore E & P and Windfarms operations. Plan and organise OSB cranes, vehicles, MHE, spaces and relevant facilities for storage, movement, and custody transfer of various types of solid and liquid cargo, tools, shackles, bulk materials in open yards and ships' gears. Be aware of potential emergency situations and how to respond and coordinate with relevant internal and external agencies. Manage safety of personnel of sub-contractors, stevedores', tenants, and ship crew, when engaged in OSB operations. Differentiate between various ships, technical and functional characteristics, safety requirements and potential hazards of each operation. Build competency in developing and maintaining documentary evidence for traceability for all works executed during the specific period or operation. Develop techniques for performance monitoring and continuous improvements based on lessons learned from each operation at the Base as well as from reports about peers in the similar business. Target Audience This course is intended for: Operations Management personnel from existing OSBs, Ports, Logistics & Warehouses, Offshore Fields, E & P Infrastructure Support services providers. Professionals who are interested in OSB segment of the Offshore & Marine Oil & Gas Industry. Participants who have no prior knowledge about OSB Operations and are new to the Offshore Logistics And highly recommended for: Managers, Engineers, and Professionals assigned to lead new initiatives in Logistics Management of Offshore & Marine Segments of Oil & Gas Industry. Course Level Intermediate Trainer Principal Management Consultant Chartered Valuer and Appraiser (CVA) FACICA | FAMTAC | FAIADR | M.S.I.D | Member, AIEN LL.M. (IP Law), M. Sc. (Maritime Studies), M. Tech (Knowledge Engineering), MBA, First Class CoC (MCA, UK), B. E. (Elect) Your expert course leader during the last 47 year period, has worked and consulted in the industry verticals encompassing: Technology, Oil & Gas Exploration & Production, Petrochemical Process Plants and Power Plant Construction Projects, Logistics & Warehousing, Marine, Offshore, Oil & Gas Pipelines, Infrastructure Development Projects (Ports, Offshore Supply Bases, Oil & Gas Terminals and Airports etc), EPCIC Contracts, and Shipyards, in South East Asia, Africa, Middle East, Americas and Europe. He serves as the Principal Management Consultant with a management consultancy in Hong Kong and Singapore, specialising in the fields of corporate management consultancy, international contracts reviews and alternative dispute resolutions services. He undertakes special assignments for conducting audits and valuation of intangible properties involving proprietary processes for licensed production, and licensing of intellectual property rights (IP Rights) in patents, trademarks, and industrial designs. He is frequently engaged for assignments like due diligence, acquisitions, mergers, resolving various operational issues, technology transfer and agency services contracts reviews, cost controls, and enhancement of Supply Chain Management. He has been conferred the credentials of Chartered Valuer & Appraiser (CVA) by SAC and IVAS, in accordance with the international valuation standards setting body IVSC. His consulting experience includes Charterparty Management, Business Process Re-engineering, Diversifications, Corporate Development, Marketing, Complex Project Management, Feasibility Studies, Dispute Resolutions and Market Research. He has successfully assisted Marine and offshore E & P clients in managing contractual disputes arising from various international contracts for upgrading & conversion projects. He continues to be actively engaged in claims reviews, mediation, arbitration, litigation, and expert witness related assignments, arising from international contracts and Charterparty Agreements. He graduated with a Bachelor's degree in Electrical Engineering, MBA in General Management, Master of Technology in Knowledge Engineering, Master of Science in Maritime Studies, and LL.M. (IP Law). He also holds professional qualifications in Business Valuations and Appraisers for CVA, arbitration, law, and marine engineering, including the Chief Engineer's First-Class Certificate of Competency (MCA, UK). He is further qualified and accredited as Certified International Arbitrator, Chartered Arbitrator, Sports arbitrator under CAS Rules, WIPO Neutral, Australian Communications and Media Authority (ACMA) Bargaining Code Arbitrator, Accredited Adjudicator and Accredited Mediator (Malaysia). He is admitted to the international panels of arbitrators and neutrals with WIPO, Geneva; ACICA, AMTAC and ACMA, Australia; BVIAC (British Virgin Islands); JIAC (Jamaica); HKIAC Hong Kong; AIAC, Malaysia; AIADR, Malaysia; KCAB, Seoul, South Korea; ICA, Delhi, India; ICC (Singapore); SISV, Singapore; SCMA, Singapore; SCCA, Saudi Arabia; VIAC Vienna, Austria; Thailand Arbitration Centre (THAC), and Mediator with AIAC Malaysia, CMC, and SIMI Singapore. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Managing Successful Programmes 5th Edition Foundation: In-House

By IIL Europe Ltd

Managing Successful Programmes (MSP®) 5th Edition Foundation: In-House Training Managing Successful Programmes (MSP®) is a globally-recognized framework for best practice programme management. MSP certification provides guidance for programme managers, business change managers and the next step for project managers to develop their knowledge and skills to be able to positively respond to the challenges for managing programmes and larger, more strategic or multiple projects. MSP 5th edition emphasizes flexibility, adaptability, and responsiveness by adopting an incremental approach to the programme lifecycle and thus enabling organizational agility. AXELOS offers two levels of MSP Examination: MSP Foundation and MSP Practitioner. The MSP Foundation Examination is intended to assess whether the candidate can demonstrate sufficient recall and understanding of the MSP programme management framework. The MSP Foundation qualification is a prerequisite for the MSP Practitioner Examination, which assesses the ability to apply understanding of the MSP programme management framework in context. The MSP® 5th Edition Foundation course is a training based on the exam specification for MSP Foundation certification and is aligned with the Managing Successful Programmes (5th Edition) guide from AXELOS. What you will Learn At the end of this course, participants will be able to: Understand key concepts relating to programmes and MSP Understand how the MSP principles underpin the MSP framework Understand the MSP themes and how they are applied throughout the programme Understand the MSP processes and how they are carried out throughout the programme Key Concepts of MSP Programmes Three Lenses of MSP Principles Themes and Governance Organization Organization Theme Organization Structure Individual Roles Stakeholder Management Design Design Theme Benefits Risk Identification and Prioritization Target Operating Model Documents and Key Roles Justification Justification Theme Business Case Financial Planning Documents and Key Roles Structure Structure Theme Delivery Planning Dependencies Benefits Realization Plan Resourcing Documents and Key Roles Knowledge Knowledge Theme Knowledge Management Information Management Document and Key Roles Assurance Assurance Theme Assurance at Multiple Levels Assurance Planning Document and Key Roles Decisions Decisions Theme Issue Resolution Risk Response Data Gathering and Reporting Options and Analysis Document and Key Roles MSP Processes Identify the Programmeâ¯â¯â¯ Design the Outcomes Plan Progressive Delivery Deliver the Capabilities Embed the Outcomes Evaluate New Information Close the Programme

Managing Successful Programmes (MSP) 5th Edition Foundation

By IIL Europe Ltd

Managing Successful Programmes (MSP®) 5th Edition Foundation Managing Successful Programmes (MSP®) is a globally-recognized framework for best practice programme management. MSP certification provides guidance for programme managers, business change managers and the next step for project managers to develop their knowledge and skills to be able to positively respond to the challenges for managing programmes and larger, more strategic or multiple projects. MSP 5th edition emphasizes flexibility, adaptability, and responsiveness by adopting an incremental approach to the programme lifecycle and thus enabling organizational agility. AXELOS offers two levels of MSP Examination: MSP Foundation and MSP Practitioner. The MSP Foundation Examination is intended to assess whether the candidate can demonstrate sufficient recall and understanding of the MSP programme management framework. The MSP Foundation qualification is a prerequisite for the MSP Practitioner Examination, which assesses the ability to apply understanding of the MSP programme management framework in context. The MSP® 5th Edition Foundation course is a training based on the exam specification for MSP Foundation certification and is aligned with the Managing Successful Programmes (5th Edition) guide from AXELOS. What you will Learn At the end of this course, participants will be able to: Understand key concepts relating to programmes and MSP Understand how the MSP principles underpin the MSP framework Understand the MSP themes and how they are applied throughout the programme Understand the MSP processes and how they are carried out throughout the programme Key Concepts of MSP Programmes Three Lenses of MSP Principles Themes and Governance Organization Organization Theme Organization Structure Individual Roles Stakeholder Management Design Design Theme Benefits Risk Identification and Prioritization Target Operating Model Documents and Key Roles Justification Justification Theme Business Case Financial Planning Documents and Key Roles Structure Structure Theme Delivery Planning Dependencies Benefits Realization Plan Resourcing Documents and Key Roles Knowledge Knowledge Theme Knowledge Management Information Management Document and Key Roles Assurance Assurance Theme Assurance at Multiple Levels Assurance Planning Document and Key Roles Decisions Decisions Theme Issue Resolution Risk Response Data Gathering and Reporting Options and Analysis Document and Key Roles MSP Processes Identify the Programmeâ¯â¯â¯ Design the Outcomes Plan Progressive Delivery Deliver the Capabilities Embed the Outcomes Evaluate New Information Close the Programme

Microsoft Active Directory course description A thorough understanding of this system is essential for anyone managing enterprise MS networks. Essential theory is complimented with a high level of hands on practice allowing delegates to observe the idiosyncrasies of Active Directory and Group Policy at first hand. Delegates learn the fundamental theory of AD and progress onto building a multi-domain network in the classroom. The course includes troubleshooting methods, and essential maintenance procedures. This course is designed to teach you the skills needed for day to day management of these technologies. What will you learn Install AD on multiple PCs. Use the tools to create and manage objects. Create appropriate group policies to restrict selected user's desktops and network access. Install DNS to support Active Directory without loosing Internet Connectivity. Maintain and troubleshoot AD problems Backup Active Directory. Microsoft Active Directory course details Who will benefit: Technical staff working with AD based networks. Prerequisites: Supporting Windows server. Duration 3 days Microsoft Active Directory course contents Introduction to Active Directory Network authentication methods, Active Directory defined, AD naming conventions, network management with AD, AD structures: Domains, Organisational Units, Forests & Trees, Sites, The Global Catalogue. Windows 2003 new features, installing AD. Hands on Installing an AD network. Windows overview Management methods Server management tools, installing the additional tools, Terminal Server: Administration mode, Administrator accounts in AD, Local Security Policy. Hands on Install the management tools, Management using Terminal Services. Creating & Managing Objects (a quick look) AD management tools, AD users and computers, Creating & managing OUs, User Accounts and groups, controlling access to AD objects, moving objects, Publishing resources, locating objects in AD, delegating authority. Hands on Creating a control OU structure and delegating authority. Introduction to Group Policies What are Group Policies? Where Group Policy data is stored, security, Group Policy flow. Hands on Implementing Group Policies Working with Group Policies Local security templates, administrative templates, scripts, folder redirection, software deployment. Hands on Scripts, redirecting the start menu, creating a secure, robust desktop environment. Implementing DNS DNS basics, troubleshooting, implementing DNS zones. Hands on Building a unified DNS solution. Maintaining and managing the AD database AD support tools, database internal structure, replication, replication tools, Single Operations Masters, tools for maintenance, maintenance techniques, Backing up AD, Directory Services restore mode, NTDSUtil, Authoritative & non-authoritative restoration, rebuilding. Hands on NTDSUtil.

Management of Value (MoV) Foundation: In-House Training

By IIL Europe Ltd

Management of Value (MoV®) Foundation This interactive MoV® Foundation course provides a modular and case-study-driven approach to learning Management of Value (MoV). The core knowledge is structured and comprehensive; and well-rounded modules cover the methodology and various techniques. A case study is used to help appreciate the relevance of MoV in its practical application. What you will Learn Upon completion of an MoV course candidates should be able to discuss and explain: The main processes and techniques used within MoV and the reasons for using them How MoV may be applied at portfolio, program, project and operational levels The differences in applying MoV at different stages in a project and the expected outputs from a MoV Study at each stage The circumstances under which MoV should be used The concept of value and how value may be improved The main benefits arising from the use of MoV Approaches for implementing MoV How to respond to external and internal influences The principles of embedding MoV into an organization The key topics in document checklists, the toolbox, health check, organizational maturity and individual competence. Upon successful completion of this course, you will be able to: Organize and contribute constructively to a Management of Value (MoV) Study Demonstrate a knowledge of MoV principles, processes, approach and environment Analyse a company, program or project to establish its organizational value; includes identification and weighting of Value Drivers Pass the AXELOS MoV Foundation Examination Introduction to value management and MoV Value and Value Management Capabilities, Outcomes, Benefits and Disbenefits What is Value? What is Management of Value (MoV)? Why use MoV? Where use MoV? When MoV should be used? What using MoV involve? Selected MoV benefits Relationship with other AXELOS Global Best Practices and Models How MoV fits with other AXELOS Global Best Practice Guides MoV principles Align with organization's objectives Focus on functions and required outcomes Balance the variables to maximise value Apply throughout the investment decision Tailor MoV to suit the subject Learn from experience and improve Assign clear roles and responsibilities and build a supportive culture MoV processes Frame the programme or project Gather information Analyse information Process information Evaluate and select Develop Value Improving Proposals Implement and share outputs MoV techniques Function Analysis Function Analysis System Technique (FAST) Traditional (or classic) FAST Technical FAST Customer FAST Value Trees Measuring value Value profiling (a.k.a. value benchmarking) Simple multi-attribute rating technique (a.k.a. SMART) Value index Value metrics Value for money (VfM) ratio Value Engineering / Analysis Common techniques used in MoV Analysis of information Benchmarking Process Mapping Root Cause Analysis Discounted Cash Flow Analysis Generating Ideas Brainstorming Evaluation and option selection Option Selection Matrix Idea selection Allocation to Categories Idea Selection Matrix Weighting techniques Paired Comparisons Points Distribution Developing VIPs Developing Proposals Cost Benefit Analysis Building Decisions Implementing VIPs Implementation Plans Feedback Following up Tracking Benefits Approach to Implementation Generic approach to MoV implementation Plan the MoV activities Understand and articulate value Prioritize value Improve value Quantify value Monitor improvements in value Learn lessons Environmental factors Portfolio Considerations Programme considerations Project considerations Operational Considerations Embedding MoV into an organization Benefits of Embedding MoV into an organization MoV Policy MoV Policy Composition Embedding MoV into an organisation Key steps Suggested MoV Management Structure Overcoming barriers We do it anyway It takes up too much time We can't afford to make the changes What's in it for me? Don't fix it if it ain't broke Fixed returns on investment MoV products Briefing Meeting Agenda (A.1) Communications Checklist (A.2) Equipment list for an Effective Study/Workshop (A.3) Invitation to join the Study Team (A.4) Option Evaluation Matrix (A.5) Plan the Study (A.6) Recording Idea Selection (A.7) Reporting Study outputs (A.8) Scoping the Study (A.9) Study or Workshop Handbook (A.10) Value-Improvement Proposal Forms (A.11) Value Improvement Tracking Report (A.12) MoV toolbox MoV health check and maturity model P3M3 Maturity Model MoV Maturity Model (aligned with P3M3)

Management of Value (MoV) Foundation

By IIL Europe Ltd

Management of Value (MoV®) Foundation This interactive MoV® Foundation course provides a modular and case-study-driven approach to learning Management of Value (MoV). The core knowledge is structured and comprehensive; and well-rounded modules cover the methodology and various techniques. A case study is used to help appreciate the relevance of MoV in its practical application. What you will Learn Upon completion of an MoV course candidates should be able to discuss and explain: The main processes and techniques used within MoV and the reasons for using them How MoV may be applied at portfolio, program, project and operational levels The differences in applying MoV at different stages in a project and the expected outputs from a MoV Study at each stage The circumstances under which MoV should be used The concept of value and how value may be improved The main benefits arising from the use of MoV Approaches for implementing MoV How to respond to external and internal influences The principles of embedding MoV into an organization The key topics in document checklists, the toolbox, health check, organizational maturity and individual competence. Upon successful completion of this course, you will be able to: Organize and contribute constructively to a Management of Value (MoV) Study Demonstrate a knowledge of MoV principles, processes, approach and environment Analyse a company, program or project to establish its organizational value; includes identification and weighting of Value Drivers Pass the AXELOS MoV Foundation Examination Introduction to value management and MoV Value and Value Management Capabilities, Outcomes, Benefits and Disbenefits What is Value? What is Management of Value (MoV)? Why use MoV? Where use MoV? When MoV should be used? What using MoV involve? Selected MoV benefits Relationship with other AXELOS Global Best Practices and Models How MoV fits with other AXELOS Global Best Practice Guides MoV principles Align with organization's objectives Focus on functions and required outcomes Balance the variables to maximise value Apply throughout the investment decision Tailor MoV to suit the subject Learn from experience and improve Assign clear roles and responsibilities and build a supportive culture MoV processes Frame the programme or project Gather information Analyse information Process information Evaluate and select Develop Value Improving Proposals Implement and share outputs MoV techniques Function Analysis Function Analysis System Technique (FAST) Traditional (or classic) FAST Technical FAST Customer FAST Value Trees Measuring value Value profiling (a.k.a. value benchmarking) Simple multi-attribute rating technique (a.k.a. SMART) Value index Value metrics Value for money (VfM) ratio Value Engineering / Analysis Common techniques used in MoV Analysis of information Benchmarking Process Mapping Root Cause Analysis Discounted Cash Flow Analysis Generating Ideas Brainstorming Evaluation and option selection Option Selection Matrix Idea selection Allocation to Categories Idea Selection Matrix Weighting techniques Paired Comparisons Points Distribution Developing VIPs Developing Proposals Cost Benefit Analysis Building Decisions Implementing VIPs Implementation Plans Feedback Following up Tracking Benefits Approach to Implementation Generic approach to MoV implementation Plan the MoV activities Understand and articulate value Prioritize value Improve value Quantify value Monitor improvements in value Learn lessons Environmental factors Portfolio Considerations Programme considerations Project considerations Operational Considerations Embedding MoV into an organization Benefits of Embedding MoV into an organization MoV Policy MoV Policy Composition Embedding MoV into an organisation Key steps Suggested MoV Management Structure Overcoming barriers We do it anyway It takes up too much time We can't afford to make the changes What's in it for me? Don't fix it if it ain't broke Fixed returns on investment MoV products Briefing Meeting Agenda (A.1) Communications Checklist (A.2) Equipment list for an Effective Study/Workshop (A.3) Invitation to join the Study Team (A.4) Option Evaluation Matrix (A.5) Plan the Study (A.6) Recording Idea Selection (A.7) Reporting Study outputs (A.8) Scoping the Study (A.9) Study or Workshop Handbook (A.10) Value-Improvement Proposal Forms (A.11) Value Improvement Tracking Report (A.12) MoV toolbox MoV health check and maturity model P3M3 Maturity Model MoV Maturity Model (aligned with P3M3)

RF fundamentals training course description Radio Frequency engineering is an important yet often overlooked area in today's wireless world. This course provides a grounding in RF theory and practice for wireless, cellular and microwave systems. What will you learn Explain the basics of RF. Describe RF propagation and antenna principles. Calculate propagation losses and link budgets. Test RF systems. RF fundamentals training course details Who will benefit: Those working with wireless, cellular and microwave systems. Prerequisites: None. Duration 2 days RF fundamentals training course contents What is RF? Definition of RF, RF wave characteristics: Frequency, wavelength, power, phase, impedance, RF history, radio signals, frequency bands, safety issues, legal issues. RF systems Microwaves, cellular/mobile RF, WLANs, other fixed wireless networks, basic RF components. Hands on Building a basic WLAN network. RF system components Transmitters: Antennas: Isotropic, Dipole, how antennas achieve gain. Modulation Schemes, bandwidth, AM, FM, FSK, PSK, QAM, QPSK, interference, performance. Hands on Interference and performance. Multiple access schemes FDMA, CDMA, TDMA, CSMA/CA. Wireless systems Cellular (GSM, UMTS), Wifi, WiMax, others: GPS, DBS, RFID, radar, Bluetooth. Hands on cellular. Spread Spectrum technologies Spread spectrum benefits and disadvantages, how it works, Direct Sequence, Frequency Hopping, hybrids. RF propagation Models, link budget, Smith chart, RF matching with the Smith chart. cell capacity, tradeoffs: power vs. bandwidth, free space, reflection, diffraction, multipath cancellation, propagation prediction and measurement tools. Hands on Smith charts. RF testing Why power rather than voltage/current, units of power, dB and dBm power conversions. Test equipment: signal generators, power meters, network analysers, spectrum analysers. RF test setups: return loss, insertion loss. Hands on RF testing.

Refining Blending

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Growing global competitiveness in the refining products' market requires an in-depth knowledge of fuel technology processes, global quality standards and quality monitoring procedures. As the global market turns to cleaner fuels with more stringent specifications, the market in which refiners operate in, is getting more sophisticated and challenging. Training Objectives Upon completion of this course, participants will be able to: Get a clear overview of processing background and how white products are produced and blended Understand the blending impact on product quality and how to deal with quality giveaways, stability of blends and specification margins Get a clear overview of fuel blending operations, blending principles, specifics and operations Understand the role of additives and how additives are selected and used to meet the specification for different products and different markets Realize the importance of specifications, their limitations and how to ensure that the product is fit for purpose Be able to correctly interpret the laboratory results Target Audience The course is intended for individuals who are interested in the field of refining blending. The following personnel will benefit from the knowledge shared in this course: Plant operative planning and scheduling specialists Oil products trading and blending personnel Laboratory supervisors and technical personnel Sales, marketing and product trading personnel Refinery market and research analysts Process and chemical Engineers Personnel from the oil, fuel, biofuel, additive and auto industries Regulatory and policy-makers personnel Course Level Basic or Foundation Trainer Your expert course leader is an experienced manager with more than 25 years of operational experience in the downstream Oil & Gas industry. She is a recognised expert in conventional, biofuels and alternative fuels with extensive experience in the crude selection process and formulation of finished products including product portfolio strategy, product quality road mapping and benchmarking. She is a long-time laboratory manager with comprehensive experience in laboratory processes, including financing, benchmarking, efficiency improvement and total quality management processes. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Energy Insurance and Risk Management

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Energy insurance is a type of insurance designed to protect businesses that work in the energy industry. This type of insurance covers a wide range of risks that are unique to the energy industry, such as damage to oil rigs, power plants, pipelines, or other energy infrastructure, as well as accidents, explosions, fires, and environmental damage. Energy insurance can also provide coverage for business interruption caused by unforeseen events that can disrupt energy production or supply, such as natural disasters, equipment breakdown, and cyber-attacks. It may also include coverage for liability and loss of income resulting from lawsuits and legal claims. Training Objectives Upon completion of this course, participants will be able to: Understand the risk sharing between oil companies and contractors Know how this is dealt within the insurance products available Understand insurer's perception of risk Create awareness of how market insurance products meet industry needs Be familiar with insurer's pricing methodologies Better understanding of the broker interface Understand technical evaluation of the coverage wordings Putting technical knowledge into practice with claims workshop Target Audience The course is intended for individuals who work in the energy industry, particularly those who are involved in managing risk or making decisions related to insurance coverage. The following personnel will benefit from the knowledge shared in this course: Insurers Brokers Adjusters Lawyers Risk Managers Treasury Contracts Legals Contract Adjustor Project Managers Course Level Basic or Foundation Trainer Your expert course leader has worked in the insurance sector for 59 years. He has worked as a broker for reputable firms, such as Marsh, where he served as the managing director of Energy Construction. He has also participated in peer review for different Lloyds Syndicates. He also served as a broker for Sedgwick, AAA, and Miller in the offshore energy sector. He has helped businesses including Shell, BP, Chevron, ConocoPhillips, Petrofina, Woodside, ENI, and Brunei Shell for their policy reviews during his career. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Search By Location

- course Courses in London

- course Courses in Birmingham

- course Courses in Glasgow

- course Courses in Liverpool

- course Courses in Bristol

- course Courses in Manchester

- course Courses in Sheffield

- course Courses in Leeds

- course Courses in Edinburgh

- course Courses in Leicester

- course Courses in Coventry

- course Courses in Bradford

- course Courses in Cardiff

- course Courses in Belfast

- course Courses in Nottingham