- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

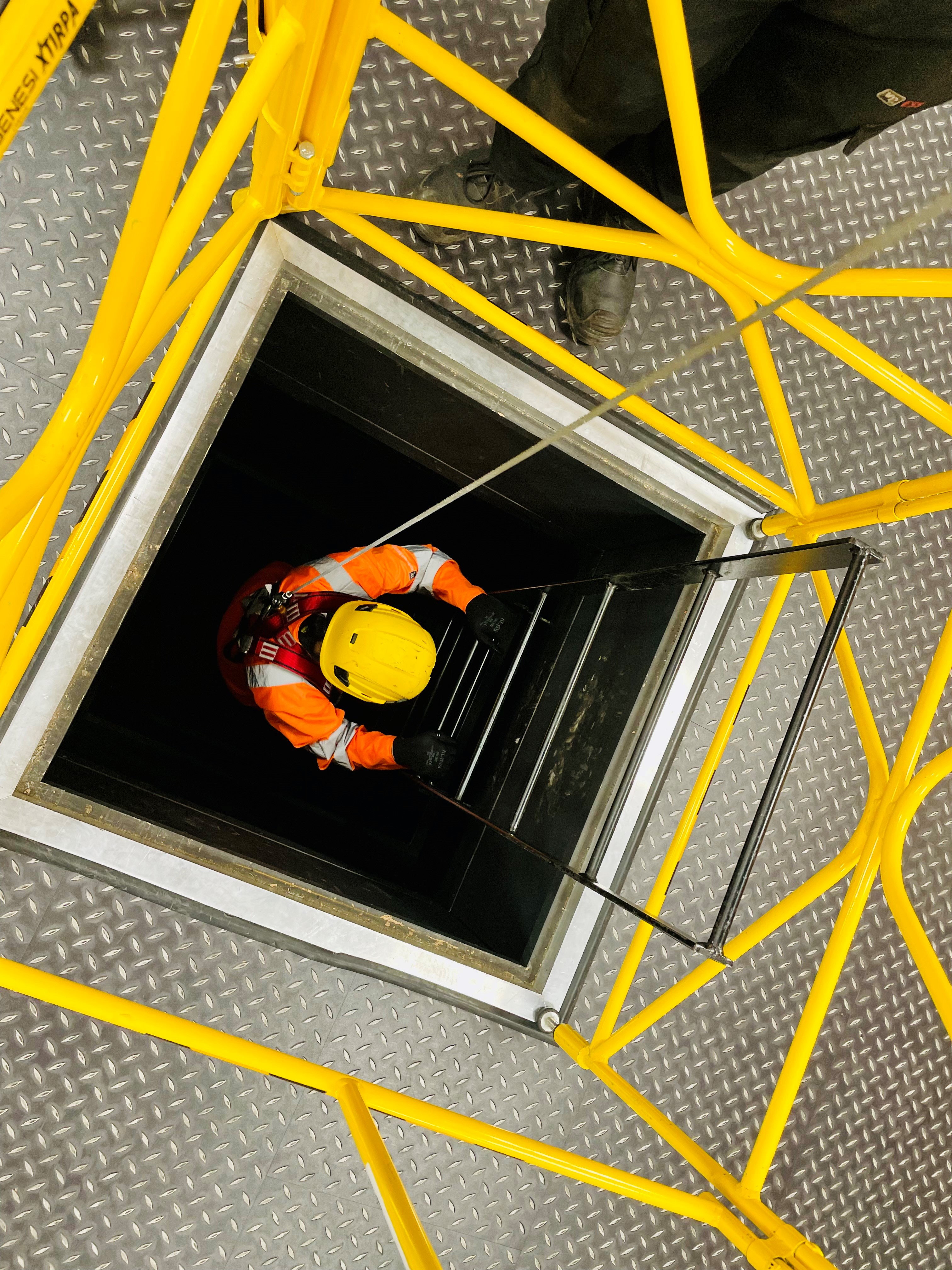

City & Guilds Level 3 Award in Direct Emergency Rescue and Recovery of Casualties from Confined Spaces - 6160-07

By Vp ESS Training

City & Guilds Level 3 Award in Direct Emergency Rescue and Recovery of Casualties from Confined Spaces - 6160-07 - This course is designed to introduce delegates to the basics of rescue and recovery of casualties from confined spaces. Understanding emergency arrangements as set by legislation and employers, some of the equipment required to rescue a casualty and safety of the rescue team. Note: A pre-requisite qualification is required to complete this course. Delegates must hold a valid 6160-08 qualification. Book via our website @ https://www.vp-ess.com/training/confined-spaces/6160-07-level-3-award-in-direct-emergency-rescue-and-recovery-of-casualties-from-cs/ or via email at: esstrainingsales@vpplc.com or phone on: 0800 000 346

City & Guilds Level 3 Award in Supervising Teams Undertaking Work in Confined Spaces - 6160-05

By Vp ESS Training

City & Guilds Level 3 Award in Supervising Teams Undertaking Work in Confined Spaces - 6160-05 - This course is designed to provide delegates with enough understanding of Safe Systems of Work to be able to authorise works and issue permits. It identifies the employer’s responsibilities within their own policies to allocate duties to competent employees. To achieve this qualification the delegate must hold the level 2 qualification relevant to their own work environment including the use confined space equipment. Book via our website @ https://www.vp-ess.com/training/confined-spaces/6160-05-city-guilds-level-3-award-in-supervising-teams-undertaking-work-in-confined-spaces/ or via email at: esstrainingsales@vpplc.com or phone on: 0800 000 346

EVI Training Course Wales

By Cenex (Centre of Excellence for Low Carbon & Fuel Cell Technologies)

The EVI Training course is a Welsh Government-funded initiative designed for local authority officers involved in the planning, coordination and delivery of public electric vehicle infrastructure. This course is for Welsh local authorities and public sector workers only and is not open to the public. This comprehensive course delves into the crucial facets of electric vehicle infrastructure (EVI), equipping participants with indispensable insights and expertise essential for navigating the dynamic landscape of electric vehicle infrastructure. Across the ten weeks, learners will cover electric vehicles (EVs) and charging technology, stakeholders, strategy, procurement, deployment and operations, empowering participants to facilitate effective EV infrastructure rollout. Participants will gain essential knowledge and skills for EVI deployment, fostering consistency and knowledge sharing across local authorities, ultimately supporting the transition to EV. / Learner Testimonial: The EVI Training course has been invaluable in improving my knowledge and confidence in EVI deployment. The course structure takes the learner through the whole process, from understanding the reasons why it’s needed, to planning, development and installation. The content has been engaging and interactive, and I’m already using what I have learnt on the course in my role at the Council. Important Information Transport for Wales have pre-funded at least one seat per Welsh local authority. Should you wish to send more than one officer, additional pre-funded seats will be considered and offered at the discretion of Transport for Wales. Each seat has a value of £2000 plus VAT. Funded seats are primarily for any local authority officer involved in EV infrastructure (EVI) delivery, with a specific focus on EVI Officers. Associated departments such as Energy, Climate Change, Procurement etc. can benefit but will only receive a pre-funded seat at the discretion of Transport for Wales. Disclaimers: Name changes can be facilitated, but once this seat has been used and the course started, it cannot be reassigned. Cancellation, Refund, & Change Policy: Cancellation Deadline: You can cancel your seat at no cost up to 2 weeks before the course start date. Seats can be deferred, subject to availability, if communicated 2 weeks before the course start date. Names can be changed if communicated a minimum of 3 working days before the course start date. Refund Policy. Transport for Wales will be subject to costs if you: If you cancel after the 2-week deadline but before 3 working days prior to the start date, a 50% refund can be offered. No refunds are eligible for cancellations made less than 3 working days before the course start date. This course is CPD accredited.

Confined Space Risk Management and Permits

By Vp ESS Training

Confined Space Risk Management and Permits - This course includes a basic level of confined space knowledge with the opportunity to use confined space equipment in a simulated environment and a team exercise of creating and reviewing a safe system of work. Note: A pre-requisite qualification is required to complete this course. Day 1 is a CS1 course and the Confined Space Risk Management (CSRM) can be completed as a 1 Day add-on. Any of following courses can be completed as a pre-requisite within 12 weeks of the CSRM; CS1, CS2, 6160-09. Book via our website @ https://www.vp-ess.com/training/confined-spaces/confined-space-risk-management-and-permits/ or via email at: esstrainingsales@vpplc.com or phone on: 0800 000 346

This ilm recognised programme builds on the coaching fundamentals to focus on enhancing the coach’s self-awareness and coaching techniques, refining both practice and skill to develop a coaching style of leadership.

In a world focused on digital media, 24-hour news channels and social channels, it’s really important to communicate with your audience – there are lots of opportunities to do this if you are interviewed by journalists. There’s the chance to deliver expert comments or take part in in-depth features or give a quote about your business or organisation. The media wants to stay relevant and engaged with its audience and you can play a part in that and talk to your audience. In our Broadcast Media Training Courses, we will teach you the best ways to share your story, how to answer those difficult questions and present yourself with confidence and style. This means you will capitalise on every opportunity. Our broadcast media and media interview training courses include: Exploiting the opportunity The world of digital media means there are lots of opportunities to appear online, on radio or on TV, as an expert or commentator and gain invaluable exposure for your business and organisation. You may meet journalists at industry events or be contacted for a comment on an issue. You may also need media training because you have to protect your business’ reputation by reacting proactively if you become involved in a news story. Media training will help you handle interviews with journalists, content creators and other media professionals. You need to communicate positively and effectively and make sure your message reaches the audience. It means speaking consistently, and with style and confidence. You’ll also need to know how to handle challenging questions and make sure you positively manage your reputation. Contemporary Media Training Our media training is interactive, engaging and importantly, carried out by experienced journalist trainers. Our team has worked at the highest levels of journalism and broadcasting and will give you an invaluable insight into how to maximise the opportunity of a media appearance. We will take you through the background of what journalists want and need, and give you a clear understanding of how to prepare and deliver your messages and ideas. We will then carry out a number of media style interviews which our technical team will record and playback so you can see and hear yourself. We will then support you with practical, inclusive and useful feedback for you to put into practice for the next interview. We provide copies of all your recordings and useful notes after the training. Locations that suit you We deliver training at our facilities in Birmingham or London or at your location, bringing our technical equipment and cameras with us. You can have a half day training session for up to 4 people or a full day training for a larger group. We also deliver training online for small groups which can be useful when teams are spread around the country. Expert Journalist Trainers We pride ourselves on two things at Coherent Comms – delivering contemporary media training and our supportive inclusive feedback. We know there are lots of media training companies out there but our clients tell us they work with us because we listen. We don’t tell you what training you need or hark back to the old days. We take on board your communication needs and deliver bespoke training. Our associates are working in digital communications, carrying out interviews for news online sites and our contacts are producing digital content for a 21st century audience. We’ll talk to you about TV and radio but we understand the wider media landscape and how to navigate it. And we’re really proud of our feedback – we want to take you from good to great and believe confidence building with tips and ideas that will work for you is the best way to develop your skills. We will help you design the course you want All our media training is bespoke and designed to exactly suit your needs. We have lots of ideas of how it might work but we want to hear from you and what you want! So get in touch with our friendly team by phone on 0754 533 4269 or fill in our contact form and we will get back to you. We’d love to hear how you hope to improve your media and communication skills.

Course Outline: What is “Diversity and Inclusion”? The Cultural Contact Lens - understanding different people's experiences The Social Ecological Model - understanding how individual elements sit within and impact upon social change Finding your ‘why’, and the Business Case for D&I Going above and beyond the Law - the Equality Act (2010) and protected characteristics Becoming comfortable with feeling uncomfortable Privilege, power, and the Cycle of Oppression An introduction to allyship Summary and questions

Utility Tracing Including use of Precision Locators

By Vp ESS Training

Focussing on utility tracing products and established safe systems of works the course aims to provide delegates with sufficient information, knowledge and confidence to conduct a utility survey and mark up. CITB grant may be available for organisations registered with the Construction Industry Training Board Book via our website @ https://www.vp-ess.com/training/utility-detection/utility-tracing-including-use-of-precision-locators/ or via email at: esstrainingsales@vpplc.com or phone on: 0800 000 346

Connections That Count: Fostering Resilience in Primary Schools - Self Esteem Workshop for Primary School Staff

By The Private Therapy Practice

Unlock the potential of your primary school students with our exclusive workshop in Essex, UK. Join us for a full-day training on 'Empowering Young Minds: Cultivating Healthy Self-Esteem in Children.' Equip your staff with practical strategies to recognize and address self-esteem challenges, fostering a positive and affirming school environment. Contact us now to book your date and invest in the well-being of your students and staff.

Level 2 Award in Fire Safety (RQF)

By NR Medical Training

The QA Level 2 Award in Fire Safety (RQF) qualification is ideal for businesses that have assigned personnel with specific fire safety responsibilities such as fire wardens or fire marshals in the workplace.

Search By Location

- EQ Courses in London

- EQ Courses in Birmingham

- EQ Courses in Glasgow

- EQ Courses in Liverpool

- EQ Courses in Bristol

- EQ Courses in Manchester

- EQ Courses in Sheffield

- EQ Courses in Leeds

- EQ Courses in Edinburgh

- EQ Courses in Leicester

- EQ Courses in Coventry

- EQ Courses in Bradford

- EQ Courses in Cardiff

- EQ Courses in Belfast

- EQ Courses in Nottingham