- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

263 Courses in Birmingham

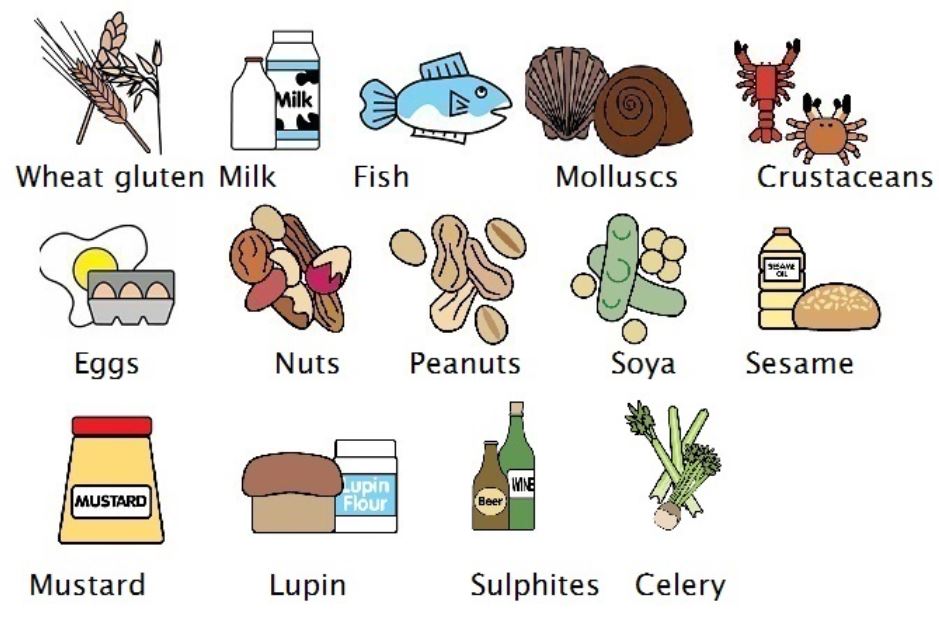

RSPH level 2 Identifying and Controlling Food Allergy Risks Training Course

By Kitchen Tonic Training Company and Food Safety Consultants

RSPH level 2 Identifying and Controlling Food Allergy Risks Training Course Do you need an allergy trainer to come to your food business and teach your staff face to face about food and drink allergens, their dangers and how to control them? Our allergy trainer can come to your business and deliver this course at your business premises. Although we are based in London, we are happy to travel and deliver this course at your business location. (Trainer travel fees may be applicable depending on your location). Staff will receive interactive training and coaching on allergens and intolerances with an experienced trainer. We can also tweak the training to include issues you would like to cover. See our website for more details. Special offer for on-site allergy training. £250 plus £20pp includes RSPH exam fees (usually £350 plus £30pp) This course is suitable for any catering business such as restaurants, pubs, hotels, cafes, catering companies, cooks, self employed, artisans, event caterers and more. This course is also important for staff who are Front of House, who take customer orders and relay the orders to cooks and chefs and other people who are preparing food for customers who have allergies and or intolerances. This is a short one day training course, typically 9am-3pm. Topics covered include- Allergens, Allergen Identification, Cross contact, Cross Contamination, Allergic Reactions, Food Intolerances, Coeliac, Anaphylaxis, Natasha's Law, UK Food Safety Regulations, Allergy Controls, Substituting ingredients, Customer Communication and what to do in an Emergency. Contact us to book training.

NPORS Crusher Training The aim of the NPORS Crusher Training is to provide theoretical and practical training for operators of Mobile Crushing equipment in the workplace. This Crusher training Course Or Test is carried out on your site using your own equipment. Please contact us for a competitive quote The Crusher Training Course is designed to provide candidates with the skills and knowledge required in order to operate a crusher safely and competently in the workplace. NPORS is an approved CSCS Partner Card Scheme, providing evidence that individuals working on construction sites have the appropriate Crusher training and qualifications for the Crusher Operation. Furthermore, training criteria is based on the approved standards of the Construction Leadership Council. Most major contractors should accept the NPORS Crusher card when presented on-site, which displays the silver CSCS logo. This NPORS crusher training meets the statutory requirements of the Health & Safety at Work Act 1974 and other relevant statutory provisions and Approved Codes of Practice. NPORS Crusher Test For Experienced Operators Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Crusher Experienced Test Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Crusher Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Click for our terms and conditions Your skills, our commitment—always at the best price. NPORS Crusher Test is for operators who have received some form of training in the past or alternatively has been operating Crusher for a number of years. If you are unsure if you qualify to go down the test route please contact us to discuss this in more detail. Discounts are available for multiple bookings There are two parts to the Crusher Test, a theory section comprised of 25 questions and a practical session operating the Crusher, revision notes are available when booking. Crusher Course Content Crushers are essential equipment in mining, quarrying, and construction industries, tasked with breaking down large rocks and materials into smaller, more manageable sizes. Operating mobile crushers requires specialised skills and knowledge to ensure safety, efficiency, and optimal performance. In this comprehensive course overview, we will explore the essential content covered in a crusher training course, designed to equip participants with the expertise needed to operate crushers safely and effectively in the workplace. 1. Introduction to Crushers: Overview of crusher types: jaw crushers, cone crushers, impact crushers, etc. Understanding the components and operating principles of crushers Different configurations and applications for specific tasks 2. Crusher Safety Procedures: Importance of safety in crusher operation Pre-operational checks and inspections Understanding crusher capacities and limitations Personal protective equipment (PPE) requirements Emergency procedures: shutdown, lockout/tagout, and evacuation protocols 3. Crusher Operation Basics: Starting, stopping, and controlling the crusher, including emergency stops Familiarisation with crusher controls: power source, conveyor belts, feeders, etc. Monitoring and adjusting crusher settings for optimal performance Understanding crusher dynamics: feed size, speed, and throughput 4. Material Handling and Crushing Techniques: Proper assessment of materials: hardness, size, and moisture content Loading and feeding materials into the crusher safely and efficiently Adjusting crusher settings for different material types and sizes Maximising crusher efficiency and product quality 5. Site Safety and Hazard Awareness: Identifying potential hazards in the crusher area Working safely around moving parts, conveyor belts, and rotating equipment Recognising environmental hazards: dust, noise, and vibration Understanding site-specific safety rules and regulations 6. Maintenance and Inspections: Importance of regular maintenance for crusher performance and reliability Daily, pre-shift, and post-shift inspection procedures Lubrication points and maintenance schedules Identifying and reporting mechanical issues and wear parts replacement 7. Practical Hands-On Crusher Training: Moving the crusher in reverse and forwards through obstructions Loading and feeding materials into the crusher using excavator and loading shovels Adjusting crusher settings and monitoring performance for efficiency Emergency response drills: simulated scenarios to test response and decision-making skills 8. Assessment and Certification: Written examination to assess theoretical knowledge Practical assessment of crusher operation skills Certification upon successful completion of the course Conclusion: A crusher training course equips participants with the essential knowledge, skills, and confidence to operate crushers safely and efficiently in various work environments. By covering topics such as safety procedures, operation techniques, material handling, site safety awareness, best maintenance practices, and practical hands-on training, participants can enhance their proficiency and contribute to a safer and more productive workplace. Whether you’re a novice operator or an experienced professional, investing in crusher training with Vally Plant Training is essential for ensuring compliance, reducing risks, and maximising productivity in crushing operations. Frequently Asked Questions About Crusher Training What is Crusher Training, and why is it necessary? Crusher Training provides individuals with the skills and knowledge required to safely and effectively operate crushers, heavy machinery used in mining, construction, and recycling industries. It’s essential for ensuring operator safety, maximising productivity, and preventing accidents on job sites. Who should undergo Crusher Training? Crusher Training is essential for anyone involved in operating or working around crushers, including quarry workers, machine operators, maintenance personnel, and site supervisors. Proper training ensures that individuals understand equipment operation procedures and safety protocols. What topics are covered in Crusher Training programs? Crusher Training programs cover a range of topics, as above, including equipment familiarisation, safety precautions, preventive maintenance, operational techniques, troubleshooting, and emergency procedures. Participants learn how to operate crushers efficiently while prioritising safety and minimising risks. How long does Crusher Training take? The duration of Crusher Training programs varies depending on factors such as the complexity of the equipment and the depth of the curriculum. Basic training courses may last a couple of days, while more comprehensive programs could extend over 1 week to cover advanced concepts and practical applications. Is Crusher Training mandatory in certain industries? While Crusher Training may not be legally mandated in all areas, many employers in the mining, construction, and recycling industries require operators to undergo training as part of their occupational health and safety policies. Compliance with training requirements helps prevent accidents and ensures regulatory compliance along with productivity. Where can I find reputable Crusher Training courses? Reputable Crusher Training courses are offered by various institutions, including industry associations, equipment manufacturers, and specialised training providers like Vally Plant Training. It’s important to choose a program that offers accredited certification and covers relevant industry standards and best practices. Crusher Courses Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable Crusher instructors, who have a wealth of knowledge of crushers and the construction industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built practical training area to simulate an actual working environment, however, Crusher Training can only be conducted on your sites Our Crusher course and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS Crusher Tester to your site nationwide, to reduce the amount of time away from work and complete the crusher test Our more courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today.

Project appraisal and risk management (In-House)

By The In House Training Company

Where should management effort be directed? In controlling costs and ensuring proper engineering in live projects? - yes, of course, but true cost control comes by understanding, eliminating and minimising risk prior to a business committing any funds. This course studies the stages required for practical financial and business appraisals of projects and capital expenditure. This course has two primary objectives: To impart the knowledge and skills required to ensure as risk-free as possible expenditure of that scarce resource, cash - the investors', governments' or shareholders' money must not be squandered To improve the quality of the appraisal process in the widest sense - demonstrating how the process of project and capital expenditure appraisal can be used to dramatically improve cost control and deliver as risk-free as possible expenditure As a result of the course, participants will be able to: Understand the economics of appraisal Be in control of their projects from the start Understand the economics of their projects - and devise the most appropriate mode Carry out sensitivity analysis and identify risk Improve their methods of appraisal and approach Focus on the risk areas and take out risk and control costs before they over-run The benefits of attending this course will be demonstrable from day one. Thorough appraisals and risk assessment follow through to success in project management and detailed cost control and project management. 1 Introduction Why appraise? Taking risk out of investment The short- and long-term results of not appraising business expenditure 2 Developing an appraisal process The process - overall and stage-by-stage objectives Understand business and technical risks Manage resources and time Do you invest enough time and effort at this stage? Take out the risks - control costs before you are committed to contracts and action Checklists 3 Appraisal arithmetic Review of the arithmetic of appraisalThe time value of moneyThe effects of different interest or required ratesThe effects of inflation (or deflation) in prices and costs Understanding the economics of appraisal is essential 4 Appraisal measures Meaning and use of appraisal measures Identifying the most appropriate measures for your particular business Payback Discounted cash flow measures - NPV and IRR Other measures - FW, AW, Profitability Index The meaning of the measures and their application in practice 5 Cost benefit analysis The effect on decision-making of more intangible benefits Cost benefit analysis Ensuring costs are genuine Measuring intangible benefits Environmental issues Consideration of intangible benefits in the appraisal decision-making process 6 Developing appropriate models Developing models - examples of spreadsheet models and measures for many different situations Modelling investment opportunities - summarising outcomes Sensitivity analysis - identifying, quantifying and taking out risk 7 Developing an appraisal process The process - managing risk from the outset Using the process in risk management, negotiating and project management Take out risk by thoroughly knowing your project - developing your own process

Anaphylaxis Awareness

By Prima Cura Training

Severe allergic reactions (anaphylaxis) can kill without immediate first aid. The UK is one of the top countries in the world for incidence of allergies. This course covers the management of anaphylaxis and the use of auto-injectors for the initial treatment of anaphylaxis.

Food Safety Trainer - Level 2 Food Safety and Hygiene Course - On-site Training - Nationwide

By Kitchen Tonic Training Company and Food Safety Consultants

Level 2 Food Safety and Hygiene in Catering Course

Combined Level 3 EFAW and Emergency Paediatric First Aid

By NR Medical Training

The Combined Emergency First Aid at Work and Emergency Paediatric First Aid course has been specifically designed to avoid the duplication of topics encountered in attending separate Emergency First Aid at Work and Emergency Paediatric First Aid courses. It is tailored for those who work in environments that require both First Aiders and Peadiatric First Aiders, such as schools, sports clubs or childcare facilities. This streamlined approach maximises efficiency and saves time for those seeking both certifications.

Risk Assessing

By Prima Cura Training

This course is designed to enable learners to increase their understanding of risk assessment and risk management in Health and Social Care settings.

Person-Cenred Care

By Prima Cura Training

Person-centred approaches are a core skills framework that articulates what it means to be person-centred and how to develop and support the workforce to work in this way. Developed in partnership with Skills for Health and Skills for Care, the Framework aims to distil best practices and to set out core, transferable behaviours, knowledge and skills. It is applicable across services and sectors and across different types of organisations. Person-centred approaches underpins existing dementia, learning disabilities, mental health and end of life care core skills frameworks. This subject forms standard 5 in The Care Certificate.

Managing Safely - IOSH Award (In-House)

By The In House Training Company

This is a very popular, comprehensive, practical and experiential programme, covering: Assessing risks: Defines and demystifies risk and risk assessment. Risk assessments and a simple scoring system are introduced, and participants carry out assessments. Controlling risks: Cutting risks down, concentrating on the best techniques to control key risks and how to choose the right methods. Understanding your responsibilities: The legal framework; health & safety management systems. Identifying hazards: The main issues any organisation has to deal with: entrances and exits, work traffic, fire, chemicals, electricity, physical and verbal abuse, bullying, stress, noise, housekeeping and the working environment, slips, trips and falls, working at height, computers and manual handling. Investigating accidents and incidents: Why accidents should be investigated, why things go wrong and how to carry out an investigation when they do. Measuring performance: How checking performance can help to improve health & safety. How to develop basic performance indicators. Auditing and proactive and reactive measuring. Protecting the environment: Introduction to waste and pollution. How organisations and individual managers can get involved in cutting down their environmental impacts. The programme enables participants to: Assess and control risks and hazards Understand their own responsibilities for safety and health Investigate incidents Measure their own performance Reflect on good practice and plan how to ensure the safety of the staff for whom they are responsible

Search By Location

- Safety Compliance Courses in London

- Safety Compliance Courses in Birmingham

- Safety Compliance Courses in Glasgow

- Safety Compliance Courses in Liverpool

- Safety Compliance Courses in Bristol

- Safety Compliance Courses in Manchester

- Safety Compliance Courses in Sheffield

- Safety Compliance Courses in Leeds

- Safety Compliance Courses in Edinburgh

- Safety Compliance Courses in Leicester

- Safety Compliance Courses in Coventry

- Safety Compliance Courses in Bradford

- Safety Compliance Courses in Cardiff

- Safety Compliance Courses in Belfast

- Safety Compliance Courses in Nottingham