- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Customer Service Excellence

By Elite Forums UK

Course Overview Outstanding customer service doesn’t happen by accident- it’s the result of clear communication, empathy, consistency, and a strong customer-focused mindset. This practical one-day course helps participants develop the mindset, skills and strategies needed to provide exceptional service and handle difficult situations with confidence and professionalism. Through real-world scenarios, role plays and interactive discussions, participants will learn how to build rapport, respond to customer needs, and create positive experiences that leave a lasting impression—whether communicating face-to-face, by phone, email, or online. Who Should Attend This course is ideal for: Frontline staff in retail, hospitality, healthcare, call centres, or public service Administration or reception staff Technical support or helpdesk officers Any team member who interacts with customers, clients or stakeholders No previous training in customer service is required. Learning Outcomes By the end of the course, participants will be able to: Understand what excellent customer service looks like and why it matters Communicate clearly, professionally and confidently in different situations Build rapport with a wide range of customers Show empathy and listen actively to understand customer needs Handle complaints, concerns and difficult conversations calmly and constructively Maintain a positive attitude, even under pressure Represent their organisation in a consistent and professional way Course Content 1. Foundations of Customer Service Excellence What is excellent customer service? First impressions and the customer journey Attitude, tone and mindset 2. Communicating with Confidence The power of words, tone and body language Active listening and questioning skills Managing expectations and saying "no" professionally 3. Creating Positive Connections Building rapport and trust quickly Adapting your style for different customers Service recovery: turning complaints into opportunities 4. Handling Difficult Situations Staying calm under pressure Responding to frustration, complaints or anger The LEAPS model for difficult conversations (Listen, Empathise, Apologise, Provide solution, Summarise) 5. Service Across Channels Delivering service via phone, email and online Professional email and message tone Tips for consistency across different platforms 6. Practical Application and Action Planning Real-life scenarios and role plays Personal action planning for immediate workplace impact Sharing service tips and best practices Delivery Method The course is delivered in an engaging, interactive format and includes: Short trainer-led discussions Scenario-based activities Role plays with coaching Group discussions and shared insights Available as a face-to-face or live virtual workshop. Inclusions Participant workbook and tools Practical checklists and communication templates Certificate of completion Access to optional post-course coaching support

Customer Service Excellence

By Elite Forums Events

Course Overview Outstanding customer service doesn’t happen by accident- it’s the result of clear communication, empathy, consistency, and a strong customer-focused mindset. This practical one-day course helps participants develop the mindset, skills and strategies needed to provide exceptional service and handle difficult situations with confidence and professionalism. Through real-world scenarios, role plays and interactive discussions, participants will learn how to build rapport, respond to customer needs, and create positive experiences that leave a lasting impression—whether communicating face-to-face, by phone, email, or online. Who Should Attend This course is ideal for: Frontline staff in retail, hospitality, healthcare, call centres, or public service Administration or reception staff Technical support or helpdesk officers Any team member who interacts with customers, clients or stakeholders No previous training in customer service is required. Learning Outcomes By the end of the course, participants will be able to: Understand what excellent customer service looks like and why it matters Communicate clearly, professionally and confidently in different situations Build rapport with a wide range of customers Show empathy and listen actively to understand customer needs Handle complaints, concerns and difficult conversations calmly and constructively Maintain a positive attitude, even under pressure Represent their organisation in a consistent and professional way Course Content 1. Foundations of Customer Service Excellence What is excellent customer service? First impressions and the customer journey Attitude, tone and mindset 2. Communicating with Confidence The power of words, tone and body language Active listening and questioning skills Managing expectations and saying "no" professionally 3. Creating Positive Connections Building rapport and trust quickly Adapting your style for different customers Service recovery: turning complaints into opportunities 4. Handling Difficult Situations Staying calm under pressure Responding to frustration, complaints or anger The LEAPS model for difficult conversations (Listen, Empathise, Apologise, Provide solution, Summarise) 5. Service Across Channels Delivering service via phone, email and online Professional email and message tone Tips for consistency across different platforms 6. Practical Application and Action Planning Real-life scenarios and role plays Personal action planning for immediate workplace impact Sharing service tips and best practices Delivery Method The course is delivered in an engaging, interactive format and includes: Short trainer-led discussions Scenario-based activities Role plays with coaching Group discussions and shared insights Available as a face-to-face or live virtual workshop. Inclusions Participant workbook and tools Practical checklists and communication templates Certificate of completion Access to optional post-course coaching support

Visual Analytics Best Practice

By Tableau Training Uk

This course is very much a discussion, so be prepared to present and critically analyse your own and class mates work. You will also need to bring a few examples of work you have done in the past. Learning and applying best practice visualisation principles will improve effective discussions amongst decision makers throughout your organisation. As a result more end-users of your dashboards will be able to make better decisions, more quickly. This 2 Day training course is aimed at analysts with good working knowledge of BI tools (we use Tableau to present, but attendees can use their own software such as Power BI or Qlik Sense). It is a great preparation for taking advanced certifications, such as Tableau Certified Professional. Contact us to discuss the Visual Analytics Best Practice course Email us if you are interested in an on-site course, or would be interested in different dates and locations This Tableau Desktop training intermediate course is designed for the professional who has a solid foundation with Tableau and is looking to take it to the next level. Attendees should have a good understanding of the fundamental concepts of building Tableau worksheets and dashboards typically achieved from having attended our Tableau Desktop Foundation Course. At the end of this course you will be able to communicate insights more effectively, enabling your organisation to make better decisions, quickly. The Tableau Desktop Analyst training course is aimed at people who are used to working with MS Excel or other Business Intelligence tools and who have preferably been using Tableau already for basic reporting. The course includes the following topics: WHAT IS VISUAL ANALYSIS? Visual Analytics Visual Analytics Process Advantages of Visual Analysis Exercise: Interpreting Visualisations HOW DO WE PROCESS VISUAL INFORMATION? Memory and Processing Types Exercise: Identifying Types of Processing Cognitive Load Exercise: Analysing Cognitive Load Focus and Guide the Viewer Remove Visual Distractions Organise Information into Chunks Design for Proximity Exercise: Reducing Cognitive Load SENSORY MEMORY Pre-attentive Attributes Quantitatively-Perceived Attributes Categorically-Perceived Attributes Exercise: Analysing Pre-attentive Attributes Form & Attributes Exercise: Using Form Effectively Colour & Attributes Exercise: Using Colour Effectively Position & Attributes Exercise: Using Position Effectively ENSURING VISUAL INTEGRITY Informing without Misleading Gestalt Principles Visual Area Axis & Scale Colour Detail Exercise: Informing without Misleading CHOOSING THE RIGHT VISUALISATION Comparing and Ranking Categories Comparing Measures Comparing Parts to Whole Viewing Data Over Time Charts Types for Mapping Viewing Correlation Viewing Distributions Viewing Specific Values DASHBOARDS AND STORIES Exercise: Picking the Chart Type Exercise: Brainstorming Visual Best Practice Development Process for Dashboards and Stories Plan the Visualisation Create the Visualisation Test the Visualisation Exercise: Designing Dashboards and Stories This training course includes over 20 hands-on exercises to help participants “learn by doing” and to assist group discussions around real-life use cases. Each attendee receives an extensive training manual which covers the theory, practical applications and use cases, exercises and solutions together with a USB with all the materials required for the training. The course starts at 09:30 on the first day and ends at 17:00. On the second day the course starts at 09:00 and ends at 17:00. Students must bring their own laptop with an active version of Tableau Desktop 10.5 (or later) pre-installed. What People Are Saying About This Course "Steve was willing to address questions arising from his content in a full and understandable way"Lisa L. "Really enjoyed the course and feel the subject and the way it was taught was very close to my needs"James G. "The course tutor Steve was incredibly helpful and taught the information very well while making the two days very enjoyable."Bradd P. "The host and his courses will give you the tools and confidence that you need to be comfortable with Tableau."Jack S. "Steve was fantastic with his knowledge and knowhow about the product. Where possible he made sure you could put demonstrations in to working practice, to give the audience a clear understanding."Tim H. "This was a very interesting and helpful course, which will definitely help me produce smarter, cleaner visualisations that will deliver more data-driven insights within our business."Richard A. "Steve is very open to questions and will go out of his way to answer any query. Thank you"Wasif N. "Steve was willing to address questions arising from his content in a full and understandable way"Lisa L. "Really enjoyed the course and feel the subject and the way it was taught was very close to my needs"James G.

Overview The objective of this course is to equip professionals with comprehensive knowledge and practical skills in WEB 3 technologies and crypto assets. Participants will gain a deep understanding of the underlying principles of blockchain, the operational mechanics of cryptocurrencies, the potential impact of these technologies on the banking sector and the latest trends. Who the course is for Consultants Analysts Managers C-Level executives People in need of knowledge to develop a blockchain strategy People working with blockchain projects Regulators Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

Overview 2 day applied course with comprehensive case studies covering both Standardized Approach (SA) and Internal Models Approach (IMA). This course is for anyone interested in understanding practical examples of how the sensitivities-based method is applied and how internal models for SES and DRC are built. Who the course is for Traders and heads of trading desks Market risk management and quant staff Regulators Capital management staff within ALM function Internal audit and finance staff Bank investors – shareholders and creditors Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

Tableau Desktop Training - Analyst

By Tableau Training Uk

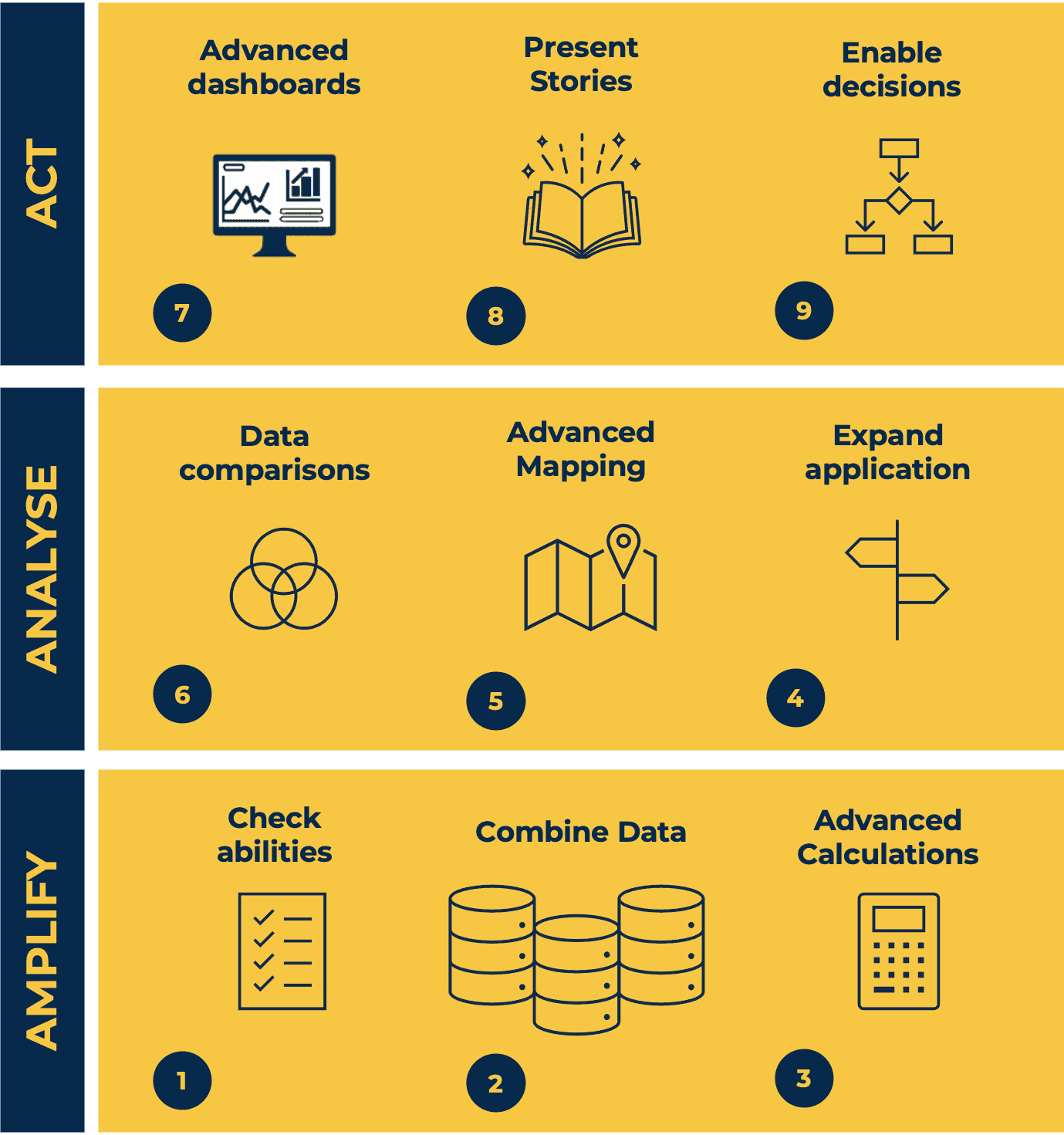

This Tableau Desktop Training intermediate course is designed for the professional who has a solid foundation with Tableau and is looking to take it to the next level. For Private options, online or in-person, please send us details of your requirements: This Tableau Desktop training intermediate course is designed for the professional who has a solid foundation with Tableau and is looking to take it to the next level. Attendees should have a good understanding of the fundamental concepts of building Tableau worksheets and dashboards typically achieved from having attended our Tableau Desktop Foundation Course. At the end of this course you will be able to communicate insights more effectively, enabling your organisation to make better decisions, quickly. The Tableau Desktop Analyst training course is aimed at people who are used to working with MS Excel or other Business Intelligence tools and who have preferably been using Tableau already for basic reporting. The course is split into 3 phases and 9 modules: Phase 1: AMPLIFY MODULE 1: CHECK ABILITIES Revision – What I Should Know What is possibleHow does Tableau deal with dataKnow your way aroundHow do we format chartsHow Tableau deals with datesCharts that compare multiple measuresCreating Tables MODULE 2: COMBINE DATA Relationships Joining Tables – Join Types, Joining tables within the same database, cross database joins, join calculations Blending – How to create a blend with common fields, Custom defined Field relationships and mismatched element names, Calculated fields in blended data sources Unions – Manual Unions and mismatched columns, Wildcard unions Data Extracts – Creating & Editing Data extracts MODULE 3: ADVANCED CALCULATIONS Row Level v Aggregations Aggregating dimensions in calculations Changing the Level of Detail (LOD) of calculations – What, Why, How Adding Table Calculations Phase 2: ANALYSE MODULE 4: EXPAND APPLICATION Making things dynamic with parameters Sets Trend Lines How do we format charts Forecasting MODULE 5: ADVANCED MAPPING Using your own images for spatial analysis Mapping with Spatial files MODULE 6: DATA COMPARISONS Advanced Charts Bar in Bar charts Bullet graphs Creating Bins and Histograms Creating a Box & Whisker plot Phase 3: ACT MODULE 7: ADVANCED DASHBOARDS Using the dashboard interface and Device layout Dashboard Actions and Viz In tooltips Horizontal & Vertical containers Navigate between dashboards MODULE 8: PRESENT STORIES Telling data driven stories MODULE 9: ENABLE DECISIONS What is Tableau Server Publishing & Permissions How can your users engage with content This training course includes over 25 hands-on exercises and quizzes to help participants “learn by doing” and to assist group discussions around real-life use cases. Each attendee receives a login to our extensive training portal which covers the theory, practical applications and use cases, exercises, solutions and quizzes in both written and video format. Students must bring their own laptop with an active version of Tableau Desktop 2018.2 (or later) pre-installed. What People Are Saying About This Course “Course was fantastic, and completely relevant to the work I am doing with Tableau. I particularly liked Steve’s method of teaching and how he applied the course material to ‘real-life’ use-cases.”Richard W., Dashboard Consulting Ltd “This course was extremely useful and excellent value. It helped me formalise my learning and I have taken a lot of useful tips away which will help me in everyday work.” Lauren M., Baillie Gifford “I would definitely recommend taking this course if you have a working knowledge of Tableau. Even the little tips Steve explains will make using Tableau a lot easier. Looking forward to putting what I’ve learned into practice.”Aron F., Grove & Dean “Steve is an excellent teacher and has a vast knowledge of Tableau. I learned a huge amount over the two days that I can immediately apply at work.”John B., Mporium “Steve not only provided a comprehensive explanation of the content of the course, but also allowed time for discussing particular business issues that participants may be facing. That was really useful as part of my learning process.”Juan C., Financial Conduct Authority “Course was fantastic, and completely relevant to the work I am doing with Tableau. I particularly liked Steve’s method of teaching and how he applied the course material to ‘real-life’ use-cases.”Richard W., Dashboard Consulting Ltd “This course was extremely useful and excellent value. It helped me formalise my learning and I have taken a lot of useful tips away which will help me in everyday work.” Lauren M., Baillie Gifford “I would definitely recommend taking this course if you have a working knowledge of Tableau. Even the little tips Steve explains will make using Tableau a lot easier. Looking forward to putting what I’ve learned into practice.”Aron F., Grove & Dean “Steve is an excellent teacher and has a vast knowledge of Tableau. I learned a huge amount over the two days that I can immediately apply at work.”John B., Mporium

360 Excavator Training Courses From The objective of the NPORS 360 Excavator Training courses is to deliver comprehensive theoretical and practical training, ensuring the safe utilisation of excavators. This course covers the proficient operation of both wheeled or tracked excavators, catering to potential Digger operators. Upon successfully completing the NPORS Excavator Training Course, participants will be awarded the red trained operator card or the NPORS Traditional card, signifying their competence in completing the 360 excavator courses. Book direct with Vally Plant Training Today. This Novice 360 Excavator courses span five days and provides personalised 1 on 1 training, offering participants a focused and tailored learning experience to enhance their skills in excavator operation. Our price is structured to 1 on 1 training helping you to gain the Digger Driver Ticket 360 Excavator courses or testing can be carried out on your site Nationwide or our site in Gloucestershire NPORS Excavator Test Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Excavator Experienced Test Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Excavator Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Click for our terms and conditions Your skills, our commitment—always at the best price. NPORS Excavator Test is for operators who have been using the excavators in the workplace for a few years or that they have had some form of in-formal training in the past. If you are unsure if you qualify to go down the test route please contact our team to discuss this in more detail. If you book this route with us you will receive revision notes for the 25 questions. Discounts are available for multiple bookings NPORS Lifting Operations, Excavator As A Crane is an add on to the excavator operator card to enable the operator to safely pick and carry underslung loads, you can add the excavator as a crane at the same time as your 360 Excavator Training Turn your Excavator red card to blue with our hassle free Excavator NVQ, for more information EXCAVATOR NVQ 360 Excavator Training Course: Mastering Operation, Safety, and Maintenance 360 Excavators are versatile and powerful pieces of machinery widely used in the construction industry for various tasks, from digging trenches to lifting heavy loads with the use of Quick Hitches and Tilt Rotators. However, operating an excavator requires more than just basic knowledge of its controls; it demands proficiency, safety consciousness, and a comprehensive understanding of its capabilities. In this detailed course outline, Vally Plant Training will delve into the essential content covered in an 360 Excavator training course, designed to equip participants with the skills and knowledge needed to operate, maintain, and safely manoeuvre excavators on construction sites. If you’re keen on mastering the art of manoeuvring those heavy-duty machines, the 360 digger training at Vally Plant Training is just what you need. This course is designed to transform you into a pro at operating 360-degree excavators, making you adept at a variety of tasks, from digging to precision handling. The program is tailored to cater to both beginners and experienced operators, ensuring that everyone walks away with valuable skills. For newcomers, there’s an extensive 5-day hands-on 360 digger training where you’ll be immersed in learning the ins and outs of these massive machines, ensuring you get ample time to practice and perfect your technique. The 360 excavator courses for a Novice are 1 on 1 training, this will give you 100% of available time on the excavator learning more than the basics to enable you to pass the NPORS 360 excavator training course first time. Introduction to 360 Excavator Training All Health and safety legislations covered Overview of excavator types and configurations Components and anatomy of an excavator Understanding hydraulic systems and controls 360 Excavator courses Safety Procedures Importance of safety in excavator operation Pre-operation inspection checklist Safe entry and exit procedures Personal protective equipment (PPE) requirements Emergency shutdown procedures 360 Excavator Operation Basics Starting and shutting down procedures Familiarisation with controls: joysticks, pedals, and switches Basic manoeuvres: moving forward, backward, turning, and slewing Operating the boom, arm, and bucket controls Operate Quick Hitches and Tilt Rotators if fitted Understanding machine stability and centre of gravity Excavation Techniques Digging trenches and excavating foundations Sloping and benching techniques for safe excavation Loading dumper trucks and stockpiling materials Precision excavation for utilities and pipelines Lifting and Rigging: Excavator as a crane Overview of Excavator lifting capacities and load charts Selecting appropriate lifting attachments Rigging techniques: using hooks, slings, and chains Safe lifting practices and procedures Excavator Maintenance Importance of regular maintenance for optimal performance Daily, weekly, and monthly maintenance checks Lubrication and greasing points Troubleshooting common issues and repairs Site Safety and Hazard Awareness Identifying and mitigating hazards on construction sites Understanding underground utilities and potential hazards Working safely near power lines and other overhead obstructions Site-specific safety protocols and regulations Practical Hands-On Training Practical exercises in operating an excavator under supervision Manoeuvring in various terrain conditions Excavation tasks: digging trenches, loading trucks, etc. Lifting and rigging exercises with simulated loads NPORS Assessment and Certification Written examination to assess theoretical knowledge Practical assessment of excavator operation skills Certification upon successful completion of the Excavator Course Excavator Variations Micro Excavator up to 1Tons: Excavator Below 10T Excavator above and below 10T Wheeled Or Tracked 180 excavator (3CX) Lifting Operations (additional) Quick Hitch Training Frequently Asked Questions 1. What is 360 excavator operator training, and why is it necessary? 360 Excavator training provides individuals with the skills and knowledge needed to safely and efficiently operate excavators, heavy machinery used in construction, mining, and other industries. It’s essential for ensuring the safety of operators, preventing accidents, and maximising productivity on job sites. All Vally Plant Trainings Excavator Novice courses are 1 on 1 training helping you to gain the digger driver ticket 2. Who should undergo 360 excavator operator training? Anyone who operates or intends to operate excavators should undergo proper excavator training. This includes construction workers, heavy equipment operators, site supervisors, and contractors. Training is also valuable for individuals seeking employment in industries where excavators are commonly used. 3. What topics are covered in excavator 360 course programs? Excavator training programs typically cover a range of topics, including equipment familiarisation, safety procedures, pre-operation inspection, proper operation techniques, trenching and excavation techniques, site hazards identification, and emergency procedures. Our Training programs include hands-on practical training. 4. How long does excavator 360 course take? The duration of excavator training programs can vary depending on factors such as the level of experience of the participants and the depth of the curriculum. Basic training courses may last anywhere from a few days to 2 weeks. Vally Plant Training can also offer shorter refresher courses for experienced Excavator operators. Contact Vally Plant Training For more information 5. Is 360 excavator training Courses mandatory? While excavator training may not be legally mandated,, many employers require operators to undergo 360 Excavator Training as part of their occupational health and safety policies. Additionally, regulatory bodies and industry associations often recommend or require training certification for operating heavy machinery like excavators on site. 6. Where can I find reputable excavator training courses? Reputable 360 excavator training courses are offered by a variety of sources, including vocational schools, community colleges, private training providers, and equipment manufacturers. It’s important to choose a program that is accredited, led by experienced instructors, and covers relevant industry standards and regulations. Additionally, employers may offer in-house training or provide recommendations for external training providers. Call Vally Plant Training for all reputable training including 360 excavator training. How much does a 360 excavator driver earn?A 360 excavator driver earns Approximately between £24,000 and £40,000 pa. This will depend on things like competence, qualifications, skills, and the amount of work you have completed over the years. holding the NPORS Excavator Operator card will give you a better chance of work.How To Apply For 360 Excavator TrainingIf you want to apply for the 360 excavator Training courses in Gloucestershire then please use our contact form to enquire about our excavator courses. Contact us to find more about the other courses that we offer, and any special offers we have running each month. Please give us as much information as possible about the course, like, is this the first time on the machine or have you had previous certification on the plant.. 360 Excavator Training Courses Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who have a wealth of knowledge of the excavator and the Construction & Agricultural industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built Excavator practical training area to simulate an actual working environment. Our 360 Excavator Training Courses and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS Excavator assessor to your site nationwide, to reduce the amount of time away from work to complete the 360 Excavator Training or travel to Vally Plant Training’s Facility in Gloucestershire. Our more courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today. Ever wondered what it feels like to take control of a 13-tonne excavator? Now’s your chance to find out with this thrilling 13T Excavator Digger Driving Experience. For a full two hours, you’ll be in the driver’s seat, operating one of these colossal machines just like the professionals you’ve seen on motorways and construction sites across the country. Under the expert guidance of the UK’s Number 1 accredited training organisation, you’ll learn how to manoeuvre this massive piece of machinery with skill and precision. From loading dumpers and moving dirt around to digging impressive holes, you’ll experience the raw power and versatility of a 13-tonne excavator first-hand. For those looking for a “NPORS Excavator Training near me,” our widespread operations make it convenient for you to access Vally Plant Trainings top-quality training no matter where you are in the UK

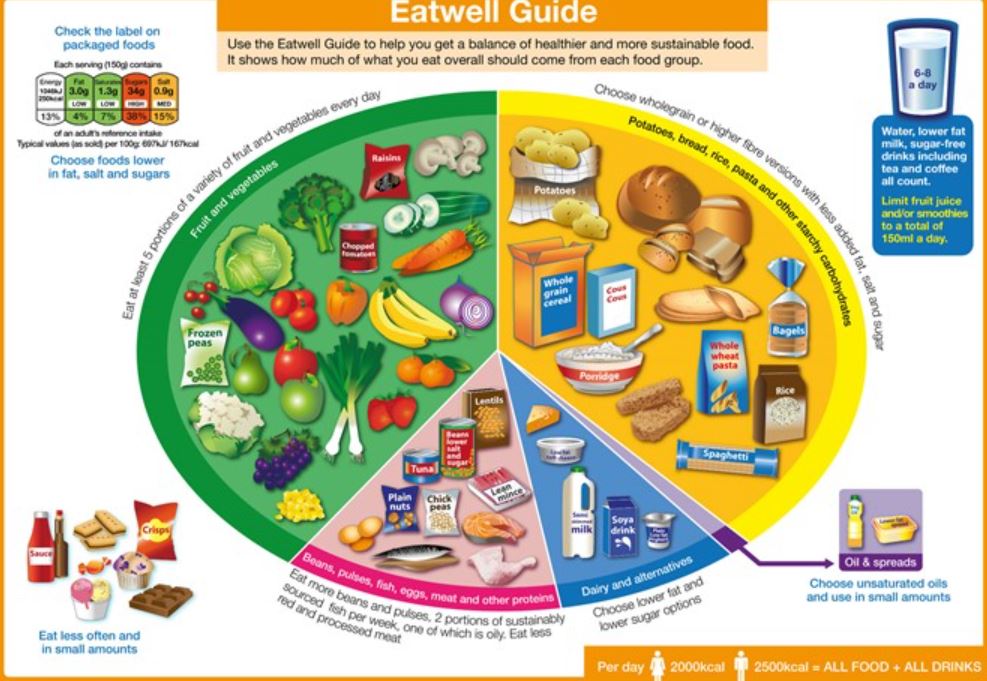

Nutrition Trainer - On-site Training - Nationwide - Level 2 Nutrition and Health Course

By Kitchen Tonic Training Company and Food Safety Consultants

Nutrition and Health Training Courses

Coaching and Mentoring

By Elite Forums UK

Course Objectives By the end of this course, participants will be able to: Differentiate between coaching and mentoring and understand their unique purposes. Apply effective communication and active listening skills in developmental conversations. Use coaching models to guide structured conversations. Build trust and psychological safety in coaching and mentoring relationships. Create actionable development plans and track progress. Understand ethical boundaries and confidentiality. Course Outline Day 1: Foundations of Coaching and Mentoring Session 1: Introduction and Context What is coaching? What is mentoring? Key differences and when to use each Benefits to individuals and organisations Session 2: Core Skills for Effective Coaching and Mentoring Active listening Powerful questioning Giving and receiving feedback Empathy and emotional intelligence Session 3: Building Trust and Creating Psychological Safety Establishing rapport Confidentiality and ethical guidelines Setting boundaries and expectations Session 4: Coaching Models and Frameworks GROW Model (Goal, Reality, Options, Will) OSKAR and CLEAR frameworks Practical application and role play Day 2: Practising and Embedding Coaching and Mentoring Session 5: The Coaching and Mentoring Conversation Structuring conversations Using real-life workplace examples Practice with feedback Session 6: Setting Goals and Development Plans SMART and CLEAR goal setting Creating growth-focused action plans Monitoring progress and accountability Session 7: Mentoring for Career and Leadership Development Mentor roles and responsibilities Supporting long-term growth and resilience Reverse mentoring and cross-generational partnerships Session 8: Embedding a Coaching and Mentoring Culture How to support coaching within your team or organisation Integrating into performance conversations Sustaining development through peer coaching and communities of practice Assessment and Evaluation Participation in discussions and practical activities Feedback on peer coaching/mentoring exercises Optional personal development plan submission Course Materials Provided Participant workbook Coaching and mentoring toolkit (templates, models, guides) Suggested reading and resource list

Coaching and Mentoring

By Elite Forums Events

Course Objectives By the end of this course, participants will be able to: Differentiate between coaching and mentoring and understand their unique purposes. Apply effective communication and active listening skills in developmental conversations. Use coaching models to guide structured conversations. Build trust and psychological safety in coaching and mentoring relationships. Create actionable development plans and track progress. Understand ethical boundaries and confidentiality. Course Outline Day 1: Foundations of Coaching and Mentoring Session 1: Introduction and Context What is coaching? What is mentoring? Key differences and when to use each Benefits to individuals and organisations Session 2: Core Skills for Effective Coaching and Mentoring Active listening Powerful questioning Giving and receiving feedback Empathy and emotional intelligence Session 3: Building Trust and Creating Psychological Safety Establishing rapport Confidentiality and ethical guidelines Setting boundaries and expectations Session 4: Coaching Models and Frameworks GROW Model (Goal, Reality, Options, Will) OSKAR and CLEAR frameworks Practical application and role play Day 2: Practising and Embedding Coaching and Mentoring Session 5: The Coaching and Mentoring Conversation Structuring conversations Using real-life workplace examples Practice with feedback Session 6: Setting Goals and Development Plans SMART and CLEAR goal setting Creating growth-focused action plans Monitoring progress and accountability Session 7: Mentoring for Career and Leadership Development Mentor roles and responsibilities Supporting long-term growth and resilience Reverse mentoring and cross-generational partnerships Session 8: Embedding a Coaching and Mentoring Culture How to support coaching within your team or organisation Integrating into performance conversations Sustaining development through peer coaching and communities of practice Assessment and Evaluation Participation in discussions and practical activities Feedback on peer coaching/mentoring exercises Optional personal development plan submission Course Materials Provided Participant workbook Coaching and mentoring toolkit (templates, models, guides) Suggested reading and resource list

Search By Location

- Practical Courses in London

- Practical Courses in Birmingham

- Practical Courses in Glasgow

- Practical Courses in Liverpool

- Practical Courses in Bristol

- Practical Courses in Manchester

- Practical Courses in Sheffield

- Practical Courses in Leeds

- Practical Courses in Edinburgh

- Practical Courses in Leicester

- Practical Courses in Coventry

- Practical Courses in Bradford

- Practical Courses in Cardiff

- Practical Courses in Belfast

- Practical Courses in Nottingham