- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

409 Courses delivered Online

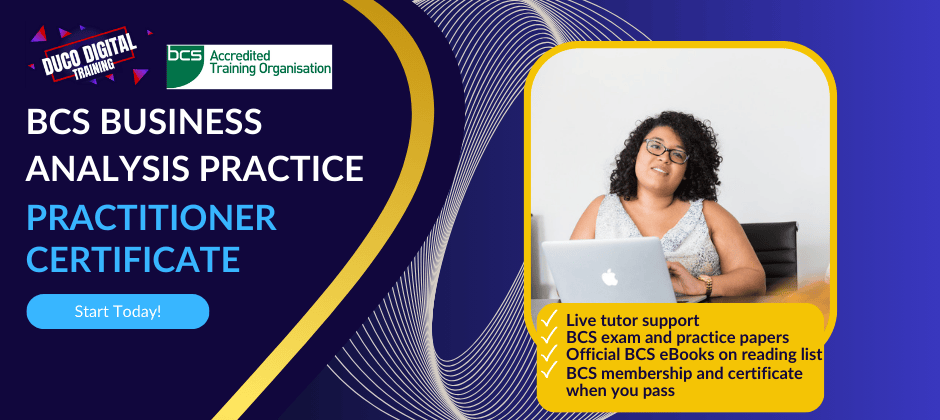

Thinking about a career in Business Analysis? The BCS Practitioner Certificate in Business Analysis has been designed to provide valuable learning for those in roles such as business analyst, business architect, business systems analyst, data analyst, enterprise analyst, management consultant, process analyst, product manager, product owner, project manager, and systems analyst.

Gain a solid foundation in business administration with our Business Administration Fundamentals Level 2 course. From understanding management principles to mastering business process management, this course prepares you for a successful career in business administration. Enrol now and take the first step towards achieving your professional goals!

Lean Six Sigma Yellow Belt Certification Program: Virtual In-House Training

By IIL Europe Ltd

Lean Six Sigma Yellow Belt Certification Program: Virtual In-House Training This course is designed to instill an in-depth understanding of Lean Six Sigma and a clear sense of what is required to define high-impact improvement projects, establish Lean Six Sigma measurements, and complete Lean Six Sigma projects using the systematic and proven Define, Measure, Analyze, Improve, and Control (DMAIC) methodology. This course is designed to instill an in-depth understanding of Lean Six Sigma and a clear sense of what is required to define high-impact improvement projects, establish Lean Six Sigma measurements, and complete Lean Six Sigma projects using the systematic and proven Define, Measure, Analyze, Improve, and Control (DMAIC) methodology. Participants will learn basic tools and techniques of Lean Six Sigma and those who pass a thirty-question exam (70% or above) will become a Certified Lean Six Sigma Yellow Belt. This course is delivered through four 3-hour online sessions. What you Will Learn You'll learn how to: Establish the structure that supports and sustains Lean Six Sigma Quality Identify and calculate key Lean Six Sigma Measurements (Sigma, DPMO, and Yield) Select successful, high-impact projects that match strategic objectives Document, measure, and improve key processes using the DMAIC (Define, Measure, Analyze, Improve, and Control) Methodology Utilize data-based thinking to make key business decisions Introduction to the Fundamentals and Vision of Lean Six Sigma Lean Six Sigma's focus on the customer, on quality, and on results The costs of poor quality Critical factors to consider when deploying Lean Six Sigma Lean Six Sigma as a process improvement methodology Lean Six Sigma metrics Why do it - ROI and payback for Lean Six Sigma Business Process Management Critical Lean Six Sigma roles and responsibilities Main aspects of managing the organizational change Project selection Metrics of Lean Six Sigma and the DMAIC Model How to strategically align business metrics and projects within an organization How to identify and measure quality characteristics which are critical to customers What does the customer (internal or external) really want from our products and services? Establishing appropriate teams and setting those teams up to be successful What defines a good measurement system? How are we doing (learning the secret to measuring the right things, right)? How to improve output measures by understanding and measuring the process Where are there defects (how to properly select and scope high-impact projects)? Where is the process broken (the Lean Six Sigma version of root cause analysis)? How to determine the process efficiency, or value add, of a process The appropriate use of quality tools Understanding the concept of variation and how to reduce knee-jerk reactions How to achieve breakthrough results for any key measure How can we ensure the identified improvements will be sustainable (the basics of process control)?

Lean Six Sigma Yellow Belt Certification Program: In-House Training

By IIL Europe Ltd

Lean Six Sigma Yellow Belt Certification Program: In-House Training This course is designed to instill an in-depth understanding of Lean Six Sigma and a clear sense of what is required to define high-impact improvement projects, establish Lean Six Sigma measurements, and complete Lean Six Sigma projects using the systematic and proven Define, Measure, Analyze, Improve, and Control (DMAIC) methodology. This course is designed to instill an in-depth understanding of Lean Six Sigma and a clear sense of what is required to define high-impact improvement projects, establish Lean Six Sigma measurements, and complete Lean Six Sigma projects using the systematic and proven Define, Measure, Analyze, Improve, and Control (DMAIC) methodology. Participants will learn basic tools and techniques of Lean Six Sigma and those who pass a thirty-question exam (70% or above) will become a Certified Lean Six Sigma Yellow Belt. This course is delivered through four 3-hour online sessions. What you Will Learn You'll learn how to: Establish the structure that supports and sustains Lean Six Sigma Quality Identify and calculate key Lean Six Sigma Measurements (Sigma, DPMO, and Yield) Select successful, high-impact projects that match strategic objectives Document, measure, and improve key processes using the DMAIC (Define, Measure, Analyze, Improve, and Control) Methodology Utilize data-based thinking to make key business decisions Introduction to the Fundamentals and Vision of Lean Six Sigma Lean Six Sigma's focus on the customer, on quality, and on results The costs of poor quality Critical factors to consider when deploying Lean Six Sigma Lean Six Sigma as a process improvement methodology Lean Six Sigma metrics Why do it - ROI and payback for Lean Six Sigma Business Process Management Critical Lean Six Sigma roles and responsibilities Main aspects of managing the organizational change Project selection Metrics of Lean Six Sigma and the DMAIC Model How to strategically align business metrics and projects within an organization How to identify and measure quality characteristics which are critical to customers What does the customer (internal or external) really want from our products and services? Establishing appropriate teams and setting those teams up to be successful What defines a good measurement system? How are we doing (learning the secret to measuring the right things, right)? How to improve output measures by understanding and measuring the process Where are there defects (how to properly select and scope high-impact projects)? Where is the process broken (the Lean Six Sigma version of root cause analysis)? How to determine the process efficiency, or value add, of a process The appropriate use of quality tools Understanding the concept of variation and how to reduce knee-jerk reactions How to achieve breakthrough results for any key measure How can we ensure the identified improvements will be sustainable (the basics of process control)?

Business Continuity Planning

By IIL Europe Ltd

Business Continuity Planning This presentation looks at a framework for defining a workable Business Continuity Plan (BCP) and the nuances required to test and maintain such a plan. This and other IIL Learning in Minutes presentations qualify for PDUs. Some titles, such as Agile-related topics may qualify for other continuing education credits such as SEUs, or CEUs. Each professional development activity yields one PDU for one hour spent engaged in the activity. Some limitations apply and can be found in the Ways to Earn PDUs section that discusses PDU activities and associated policies. Fractions of PDUs may also be reported. The smallest increment of a PDU that can be reported is 0.25. This means that if you spent 15 minutes participating in a qualifying PDU activity, you may report 0.25 PDU. If you spend 30 minutes in a qualifying PDU activity, you may report 0.50 PDU.

Business Continuity Planning

By IIL Europe Ltd

Business Continuity Planning This presentation looks at a framework for defining a workable Business Continuity Plan (BCP) and the nuances required to test and maintain such a plan. This and other IIL Learning in Minutes presentations qualify for PDUs. Some titles, such as Agile-related topics may qualify for other continuing education credits such as SEUs, or CEUs. Each professional development activity yields one PDU for one hour spent engaged in the activity. Some limitations apply and can be found in the Ways to Earn PDUs section that discusses PDU activities and associated policies. Fractions of PDUs may also be reported. The smallest increment of a PDU that can be reported is 0.25. This means that if you spent 15 minutes participating in a qualifying PDU activity, you may report 0.25 PDU. If you spend 30 minutes in a qualifying PDU activity, you may report 0.50 PDU.

Leadership and Management: Part 1 (Fundamentals)

By iStudy UK

Course Description Deepen your understanding of leadership and management from the Leadership and Management: Part 1 (Fundamentals) course. Here you will comprehend the core concept of management and leadership. The course will introduce you to leadership theories. You will pick up the strategies to improve your leadership performance. The course will show you how to build high performing teams. You will also learn about business process management from the course. The Leadership and Management: Part 1 (Fundamentals) course is a golden opportunity to grasp some valuable skills; enrol today! Learning outcome Understand the fundamentals of leadership and management Familiarise with the leadership theories Learn how to improve your leadership and management skills Deepen your knowledge about business process management How Much Do Leaders Earn? Senior - £44,000(Appx.) Average - £26,000(Appx.) Starting - £19,000(Appx.) Requirement Our Leadership and Management: Part 1 (Fundamentals) is fully compatible with any kind of device. Whether you are using Windows computer, Mac, smartphones or tablets, you will get the same experience while learning. Besides that, you will be able to access the course with any kind of internet connection from anywhere at any time without any kind of limitation. Leadership and Management: Part 1 (Fundamentals) Module 01: Understanding Management and Leadership 00:40:00 Module 02: Leadership Theories 00:25:00 Module 03: Improving Management and Leadership Performance 00:15:00 Module 04: High Performance Teams 00:32:00 Module 05: Business Process Management 00:28:00 Assignment Assignment - Leadership and Management: Part 1 (Fundamentals) 00:00:00