- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Commissioning of Electrical Equipment

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 5 full-day course provides a comprehensive understanding of all the commissioning and start-up activities of all electrical equipment including transformers, switchgear, induction and synchronous motors, generators and auxiliaries. All commissioning activities are covered in detail in this course. This includes all the commissioning procedures and documents, purpose of commissioning, responsibilities, system description, documentation, testing and commissioning schedules, test reports, safety, certification, and plant completion report. The course provides also a thorough understanding of all the commissioning requirements for transformers, switchgear, induction and synchronous motors and, generator and auxiliaries including its switchgear equipment, switchgear, and transformers. All the stages of the commissioning procedure are covered in-depth in this course. This includes preparation - planning various activities, pre-commissioning checks and tests, typical commissioning schedule, detailed tests and commissioning procedures for every type of transformers, switchgear, induction and synchronous motors, and generators and auxiliary systems, instrumentation, trial run of the equipment, safety and precautions, commissioning of electrical systems, Safety Rules Clearance Certificates, procedure for the control and handling of defects, Commissioning Reports. This course is a MUST for anyone who is involved in the pre-commissioning or commissioning of any electrical equipment because it provides detailed pre-commissioning checks and tests and detailed tests and commissioning procedures for every electrical equipment. In addition, the course provides in-depth coverage of all preparation, planning activities, commissioning schedules, trial run of each electrical equipment, safety and precautions, Safety Rules Clearance Certificates, Procedures for handling defects, and Commissioning Reports. Training Objectives Pre-Commissioning Checks and Tests, Detailed Tests and Commissioning Procedures and Instructions for all Electrical Equipment: Gain a thorough understanding of all pre-commissioning checks and tests, and all commissioning procedures and instructions for all electrical equipment Commissioning Procedures, Documents, and Certification of Electrical Equipment: Discover the benefits of the Commissioning Management System of electrical equipment including all commissioning procedures and documents, purpose of commissioning, responsibilities, system description, documentation, testing and commissioning schedules, test reports, safety, equipment certification, and commissioning completion report Commissioning Procedures for Transformers: Learn about the commissioning procedures for transformers including functional checks, pre-commissioning tests, commissioning tests, and records. Commissioning Procedures for Switchgear Assemblies: Gain a thorough understanding of all the commissioning procedures for switchgear assemblies including substation commissioning, electrical testing, code requirements, safety rules, grounding and shorting, high power testing, NETA acceptance testing procedures, test values analysis, and commissioning forms Commissioning Procedures for Generator and Auxiliaries: Discover all the commissioning procedures for generator and auxiliaries including generator, seal oil system, hydrogen gas system, stator water system, rolling and payment of generator Commissioning Procedures and Instructions for Generator Electrical Equipment: Learn about all the commissioning procedures and instructions for generator electrical equipment including switchyard equipment, switchgear, transformers, and motors Code Requirements for Commissioning Electrical Equipment and Systems: Learn about the code requirements for commissioning transformers, switchgear, inductions and synchronous motors, and generators and auxiliaries Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Course Level Basic or Foundation Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: 'ELECTRICAL EQUIPMENT HANDBOOK' published by McGraw-Hill in 2003 (600 pages) ELECTRICAL EQUIPMENT COMMISSIONING MANUAL (includes practical information about all pre-commissioning checks and tests, typical commissioning schedule, detailed tests and commissioning procedures and instructions for all electrical equipment - 500 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

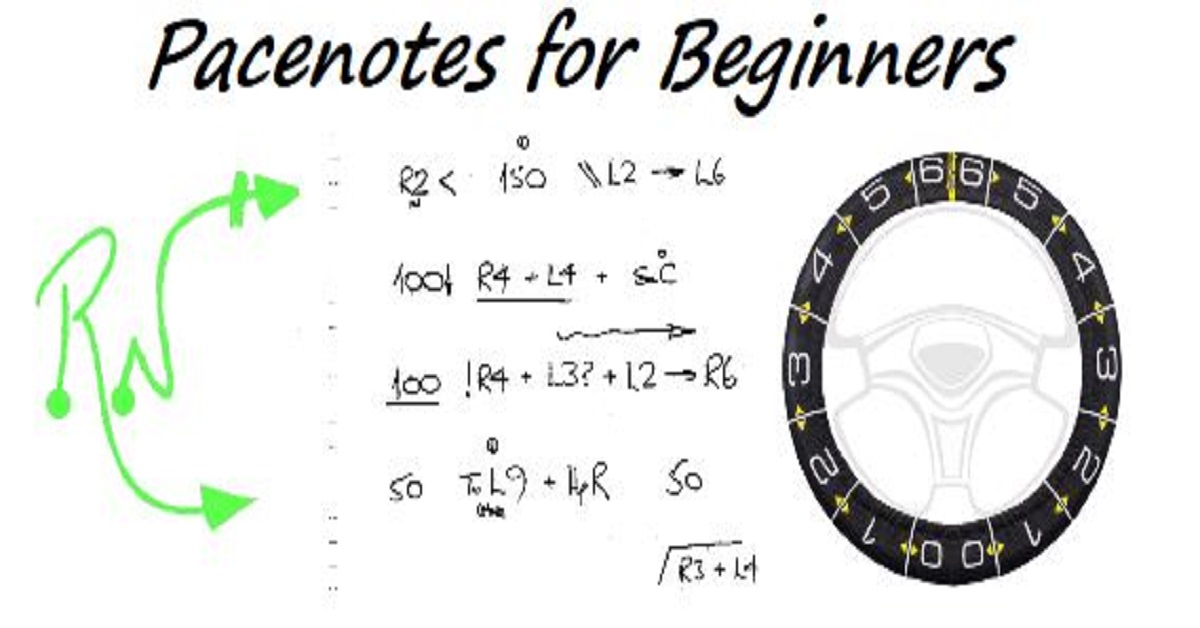

Rally Pacenote Writing for Beginners

By Rally Navigation Training Services

Rally training webinar covering making pace notes for special stage rallying.

Learn how to test portable electrical appliances with a qualification in Electrical Equipment Maintenance and Testing. Aimed at practicing electricians this qualification will help and progress individuals within the Electrotechnical industry. This qualification is aimed at those with responsibilities for the maintenance of electrical equipment and for those undertaking practical inspection and testing of electrical equipment. It allows those with the responsibility for the testing and inspection of electrical equipment to gain a qualification suitable to their job role. The qualification allows candidates to learn, develop and practise the skills required to inspect and test items of electrical equipment in line with the latest edition of the Code of Practice for In-Service Inspection and Testing of Electrical Equipment. If you already work as an electrician it will add another string to your bow and can help you move up in the industry. Learners completing the qualification will have the ability to carry out mandatory responsibilities within the workplace depending on their prior electrical knowledge This level will suit you if you are a practising electrician either involved in, or looking to become involved in, the inspection and testing of electrical equipment. To successfully complete the qualification learners will have to sit an Evolve on-line test comprising of a 50 MCQ and a practical assignment. The practical consists of 3 tasks which are: Task 1 is inspect and test Class I equipment, Task 2 is inspect and test Class II equipment (this will be either unearthed metal or without unearthed metal or Class II FE – Learners will not need to do all 3 of these, they only need to do one type), Task 3 is completing the record forms

VAL05: Equipment Cleaning Validation

By Zenosis

Manufacturers of medicines and healthcare products must establish, validate and maintain an equipment cleaning programme. This is a regulatory requirement because validated cleaning procedures contribute to the assurance of product purity and safety. This module provides a comprehensive account of equipment cleaning validation requirements and procedures. It follows the work of a pharmaceutical company's validation team as they establish and validate the cleaning program for a new production line.

Learn to craft top-notch videos for your business using your mobile phone in this interactive workshop. Enhance marketing, visibility, and attract more clients through video. All-in-one workshop for diving into the world of business videos. #VideoCreation #BusinessBoost

Assessing Display Screen Equipment IIRSM & CPD Approved

By BAB Business Group

Our display screen equipment courses are aimed at users of display screen equipment (DSE) and those responsible for assessing display screen equipment. A ‘user’, is anyone who regularly uses display screen equipment for a significant part of their normal work. In practice, if you use display screen equipment continuously for more than one hour a day, then you’re a ‘user’. So what do we mean by display screen equipment? The first thing most people think of is a computer monitor. But that’s not the only thing it refers to Display screen equipment could also mean laptops, tablet PCs, televisions, smartphones, CNC control pads, portable diagnostic screens or equipment containing cathode ray tubes, or CRTs. The Health and Safety (Display Screen Equipment) Regulations contain special directives covering DSE safety. Both employers and employee‐users have responsibilities under the legislation. This course fulfils your statutory training obligations and covers among other things, the correct way to set up and use your display screen equipment safely. Reducing the risk of work related conditions.

Display Screen Equipment Awareness IIRSM & IOSH Approved

By BAB Business Group

Our display screen equipment courses are aimed at users of display screen equipment (DSE) and those responsible for assessing display screen equipment. A ‘user’, is anyone who regularly uses display screen equipment for a significant part of their normal work. In practice, if you use display screen equipment continuously for more than one hour a day, then you’re a ‘user’. So what do we mean by display screen equipment? The first thing most people think of is a computer monitor. But that’s not the only thing it refers to Display screen equipment could also mean laptops, tablet PCs, televisions, smartphones, CNC control pads, portable diagnostic screens or equipment containing cathode ray tubes, or CRTs. The Health and Safety (Display Screen Equipment) Regulations contain special directives covering DSE safety. Both employers and employee‐users have responsibilities under the legislation. This course fulfils your statutory training obligations and covers among other things,,, the correct way to set up and use your display screen equipment safely. Reducing the risk of work related conditions.

Maintenance, Inspection, Diagnostics, Testing, Troubleshooting, Refurbishment, & Protective Systems For All Key Electrical Equipment

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 5 full-day course provides a comprehensive understanding of all the maintenance, inspection, diagnostics, testing, troubleshooting, refurbishment, and protective systems of all key electrical equipment including: transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries. It will cover in detail all the inspection methods and tests required to identify faults and deficiencies in electrical equipment, as well as, the repair techniques and available refurbishment methods. The course will also cover the activities required to commission this equipment and it will also cover all protective systems associated with this equipment. The objective of the seminar is to maximize the efficiency, reliability, and longevity of this type of equipment by providing an understanding of the common problems and repair techniques, preventive and predictive maintenance. Training Objectives Electrical Equipment Testing and Maintenance: Gain a thorough understanding of all the testing and maintenance required for all key electrical equipment including transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Electrical Equipment Inspection and Diagnostics: Learn about the inspection and diagnostics required for all the components of transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Electrical Equipment Troubleshooting: Determine all the troubleshooting activities required to minimize the downtime and operating cost of transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Electrical Equipment Online Condition Monitoring: Learn about online condition monitoring of transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Electrical Equipment Repair and Refurbishment: Obtain a detailed understanding of the various methods used to repair and refurbish transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Efficiency, Reliability, and Longevity: Learn the various methods used to maximize the efficiency, reliability, and longevity of transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Rotating Equipment Vibration Analysis and Balancing Methods: Learn about vibration analysis and balancing methods of motors and generators. Electrical Equipment Codes and Standards: Learn all the codes and standards applicable for transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Equipment Causes and Modes of Failure: Understand the causes and modes of failure of transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Generator Upgrades and Rewinds: Learn the various methods used to upgrade and rewind a generator Protective Systems: Obtain a detailed understanding of all protective systems required for transformers, inverters, rectifiers, switchgear and circuit breakers, relays and protective devices, cables and accessories, motors, variable frequency drives, uninterruptible power systems, generators, fuses, and industrial batteries Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals (this course is suitable for individuals who do not have an electrical background) Course Level Basic or Foundation Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: The relevant material of the 'ELECTRICAL EQUIPMENT HANDBOOK' published by McGraw-Hill in 2003 (600 pages) Electrical Equipment Maintenance, inspection, diagnostics, testing, troubleshooting, refurbishment, and protective systems Manual (500 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Voice Equipment

By IOMH - Institute of Mental Health

Overview of Voice Equipment Course The UK voice-over industry is growing fast, with its value expected to reach £550 million by 2026. More people are listening to audiobooks, which saw a 43% increase last year, and over 15 million people in the UK now listen to podcasts regularly. Because of this rise in audio content, learning about voice equipment is becoming more important than ever. This Voice Equipment Course helps you understand everything you need to record high-quality voice content. You will learn how to choose the right microphone, set up your home recording space, and understand acoustic treatment. The course also shows you how to work with voice equipment, set it up correctly, and keep it in good condition. You’ll also get hands-on practice with editing your recordings using voice-over software used by professionals. Whether you’re just starting your home studio or looking to improve what you already have, this Voice Equipment Course is designed to guide you at every stage. The voice equipment knowledge you gain here is useful in many industries, such as advertising, gaming, animation, and business presentations. With clear lessons and practical advice, the Voice Equipment Course helps you build the skills needed to create clear and professional voice recordings that meet today's industry standards. This Voice Equipment course will help you to learn: Know the main tools and equipment needed for voice over work Pick the right microphone for different voice over jobs Set up headphones and speakers for clear voice recording Connect and use audio interfaces and preamps for better sound Set up your room with sound treatment for better voice quality Use editing software to clean up and improve your voice recordings Who is this course for? New voice-over artists who want to set up their first home studio Content creators who want better sound for podcasts, videos, or online content Audio workers who want to focus on voice recording and equipment People moving from simple setups to more professional voice equipment Home studio owners who want to fix sound problems and improve their current setup Process of Evaluation After studying the course, an MCQ exam or assignment will test your skills and knowledge. You have to get a score of 60% to pass the test and get your certificate. Certificate of Achievement Certificate of Completion - Digital/PDF Certificate After completing the Voice Equipment course, you can order your CPD-accredited Digital/PDF Certificate for £5.99. Certificate of Completion - Hard copy Certificate You can get the CPD Accredited Hard Copy Certificate for £12.99. (Each) Shipping Charges: Inside the UK: £3.99 International: £10.99 Requirements There is no prerequisite to enrol in this course. Career Path This Voice Equipment Course will help the learners to pursue a variety of careers. Such as: Voice Over Artist – £25,000 to £45,000 a year Podcast Producer – £22,000 to £38,000 a year Audio Engineer (Voice Specialist) – £28,000 to £52,000 a year Voice Director – £35,000 to £60,000 a year Studio Technical Consultant – £32,000 to £55,000 a year Course Curriculum Module 1: Introduction to Voice Over Equipment Introduction to Voice Over Equipment 00:17:00 Module 2: Microphones for Voice Over Microphones for Voice Over 00:21:00 Module 3: Headphones and Monitoring Headphones and Monitoring 00:22:00 Module 4: Audio Interfaces and Preamps Audio Interfaces and Preamps 00:23:00 Module 5: Acoustic Treatment and Studio Setup Acoustic Treatment and Studio Setup 00:23:00 Module 6: Voice Over Software and Editing Tools Voice Over Software and Editing Tools 00:22:00 Module 7: Equipment Maintenance and Troubleshooting Equipment Maintenance and Troubleshooting 00:22:00

Follow your dreams by enrolling on the Laboratory Equipment and Solutions course today and develop the experience, skills and knowledge you need to enhance your professional development. Laboratory Equipment and Solutions will help you arm yourself with the qualities you need to work towards your dream job. Study the Laboratory Equipment and Solutions training course online with Janets through our online learning platform and take the first steps towards a successful long-term career. The Laboratory Equipment and Solutions course will allow you to enhance your CV, impress potential employers, and stand out from the crowd. This Laboratory Equipment and Solutions course consists of a number of easy to digest, in-depth modules, designed to provide you with a detailed, expert level of knowledge. Study the Laboratory Equipment and Solutions course through a mixture of instructional video lessons and online study materials. Receive online tutor support as you study the Laboratory Equipment and Solutions course, to ensure you are supported every step of the way. Get a digital certificate as proof of your Laboratory Equipment and Solutions course completion. Janets is one of the top online training course providers in the UK, and we want to make education accessible to everyone! Learn the essential skills you need to succeed and build a better future for yourself with the Laboratory Equipment and Solutions course. The Laboratory Equipment and Solutions course is designed by industry experts and is tailored to help you learn new skills with ease. The Laboratory Equipment and Solutions is incredibly great value and allows you to study at your own pace. With full course access for one year, you can complete the Laboratory Equipment and Solutions when it suits you. Access the Laboratory Equipment and Solutions course modules from any internet-enabled device, including computers, tablets, and smartphones. The Laboratory Equipment and Solutions course is designed to increase your employability and equip you with everything you need to be a success. Enrol on the Laboratory Equipment and Solutions now and start learning instantly! What You Get Out Of Studying Laboratory Equipment and Solutions With Janets Free PDF certificate upon successful completion of the Laboratory Equipment and Solutions Full one-year access to Laboratory Equipment and Solutions Course materials Instant assessment results with the Laboratory Equipment and Solutions No hidden fees with the Laboratory Equipment and Solutions Full tutor support available from Monday to Friday with the Laboratory Equipment and Solutions Study the Laboratory Equipment and Solutions at your own pace Benefit from instant feedback through mock exams and multiple-choice assessments Gain a complete understanding of Laboratory Equipment and Solutions Accessible, informative modules taught by expert instructors Get 24/7 help or advice from our email and live chat teams with the Laboratory Equipment and Solutions Study the Laboratory Equipment and Solutions in your own time through your computer, tablet or mobile device Improve your chance of gaining professional skills and better earning potential by completing the Laboratory Equipment and Solutions Description The Laboratory Equipment and Solutions training course is delivered through Janets' online learning platform. Access the Laboratory Equipment and Solutions content from any internet-enabled device whenever or wherever you want to. The Laboratory Equipment and Solutions course has no formal teaching deadlines, meaning you are free to complete the course at your own pace. Method of Assessment To successfully complete the Laboratory Equipment and Solutions course, students will have to take an automated multiple-choice exam. This exam will be online and you will need to score 60% or above to pass the Laboratory Equipment and Solutions course. After successfully passing the Laboratory Equipment and Solutions course exam, you will be able to apply for a CPD-accredited certificate as proof of your Laboratory Equipment and Solutions qualification. Certification All students who successfully complete the Laboratory Equipment and Solutions course can instantly download their digital certificate. You can also purchase a hard copy of the Laboratory Equipment and Solutions course certificate, which will be delivered by post for £9.99. Who Is This Course For: The Laboratory Equipment and Solutions is ideal for those who already work in this sector or are an aspiring professional. This Laboratory Equipment and Solutions course is designed to enhance your expertise and boost your CV. Learn key skills and gain a professional qualification to prove your newly-acquired knowledge. Requirements: The Laboratory Equipment and Solutions is open to all students and has no formal entry requirements. To study the Laboratory Equipment and Solutions course, all your need is a passion for learning, a good understanding of English, numeracy, and IT skills. You must also be over the age of 16. Career Path: The Laboratory Equipment and Solutions is ideal for anyone who wants to pursue their dream career in a relevant industry. Learn the skills you need to boost your CV and go after the job you want. Complete the Laboratory Equipment and Solutions and gain an industry-recognised qualification that will help you excel in finding your ideal job. Course Content Laboratory Equipment and Solutions Module 01: Laboratory Equipment (Part-01) Laboratory Equipments (Part-01) 00:27:00 Module 02: Laboratory Equipment (Part-02) Laboratory Equipments (Part-02) 00:16:00 Module 03: Microscope and How to Use it Microscope and How to Use It 00:18:00 Module 04: Solutions Used in Clinical/Medical Laboratory Solutions Used in Clinical/Medical Laboratory 00:18:00 Mock Exam Mock Exam - Laboratory Equipment and Solutions 00:20:00 Final Exam Final Exam - Laboratory Equipment and Solutions 00:20:00 Frequently Asked Questions Are there any prerequisites for taking the course? There are no specific prerequisites for this course, nor are there any formal entry requirements. All you need is an internet connection, a good understanding of English and a passion for learning for this course. Can I access the course at any time, or is there a set schedule? You have the flexibility to access the course at any time that suits your schedule. Our courses are self-paced, allowing you to study at your own pace and convenience. How long will I have access to the course? For this course, you will have access to the course materials for 1 year only. This means you can review the content as often as you like within the year, even after you've completed the course. However, if you buy Lifetime Access for the course, you will be able to access the course for a lifetime. Is there a certificate of completion provided after completing the course? Yes, upon successfully completing the course, you will receive a certificate of completion. This certificate can be a valuable addition to your professional portfolio and can be shared on your various social networks. Can I switch courses or get a refund if I'm not satisfied with the course? We want you to have a positive learning experience. If you're not satisfied with the course, you can request a course transfer or refund within 14 days of the initial purchase. How do I track my progress in the course? Our platform provides tracking tools and progress indicators for each course. You can monitor your progress, completed lessons, and assessments through your learner dashboard for the course. What if I have technical issues or difficulties with the course? If you encounter technical issues or content-related difficulties with the course, our support team is available to assist you. You can reach out to them for prompt resolution.