- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

286 Courses delivered Online

CT12: How to Conduct Clinical Research Under the EU Clinical Trials Regulation

By Zenosis

This course describes the requirements that must be met by, and options available to, the sponsor during the conduct of an authorised clinical trial. It identifies the various interactions with MSCs that occur via the Clinical Trials Information System (CTIS), and it summarises and links to the extensive guidance available from the European Commission and the European Medicines Agency. Its companion course CT11 sets out the European legal and regulatory context for clinical trials and describes how to apply via the CTIS for authorisation to conduct trials. The two courses therefore provide an ideal foundation for understanding and complying with the new law.

MD01: An Introduction to the Regulation of Medical Devices

By Zenosis

This module provides an introduction to the basics of medical device regulation, especially the requirements that manufacturers must meet in order to market devices in Europe and the USA.

ICT02: Assuring Data Integrity in the Manufacture of Medicinal Products

By Zenosis

Pharmaceutical and biotechnology companies and researchers need to assure regulatory authorities of the reliability of the data that they generate or acquire during product development and manufacturing – that is, to demonstrate data integrity. Data integrity is assessed during regulatory inspections of manufacturing and research sites. Inadequacies of data integrity are frequently reported by inspectors and result in regulatory actions against the companies or individuals concerned. Practices that assure data integrity are required by law and/or expected by regulators in the fields of nonclinical and clinical research, manufacturing and distribution, and pharmacovigilance of medicinal products. This course explains the requirements and describes principles and practices that should be followed to assure regulators and contractual partners of data integrity in the manufacture of medicinal products.

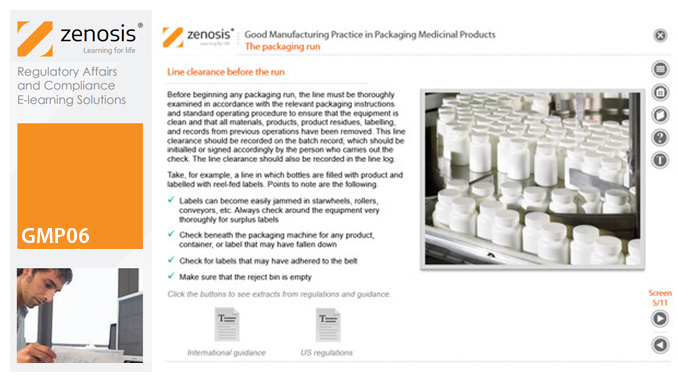

GMP06: Good Manufacturing Practice in Packaging Medicinal Products

By Zenosis

Packaging for medicinal products is subject to Good Manufacturing Practice rules similar to those for the products themselves. In this module we describe the functions that packaging must fulfil and the quality controls that are applied to packaging materials and operations. We set out the requirements for control of printed materials. We describe preparation, in-process control, and completion of a packaging run. Finally, we explain how to carry out reconciliation of packaging materials.

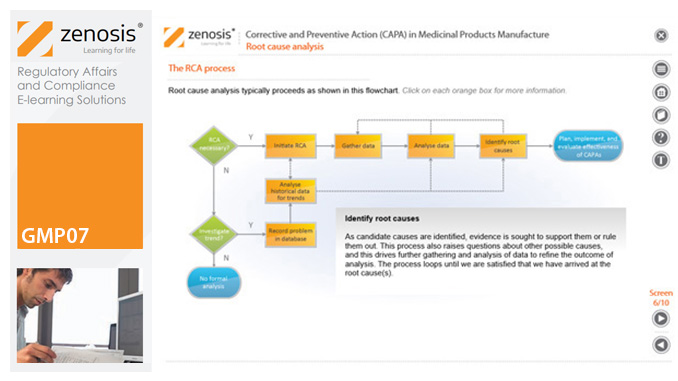

GMP07: Corrective and Preventive Action (CAPA) in Medicinal Products Manufacture

By Zenosis

A company’s Corrective and Preventive Action (CAPA ) system establishes how personnel should deal with manufacturing problems that have occurred or that may occur if not prevented. This module explains the principles of corrective and preventive action and describes typical CAPA procedure. It goes on to introduce root cause analysis and outline the role of progress tracking, escalating, and trending of CAPA procedures.

GMP03: Good Manufacturing Practice in Cleaning and Sanitation

By Zenosis

Cleaning and sanitation of premises and equipment are essential to efforts to prevent contamination of product, and they need to be done in compliance with Good Manufacturing Practice (GMP) regulatory requirements. This module shows why it is so important to do a good job, what to consider before and during each job, and how best to go about the work.

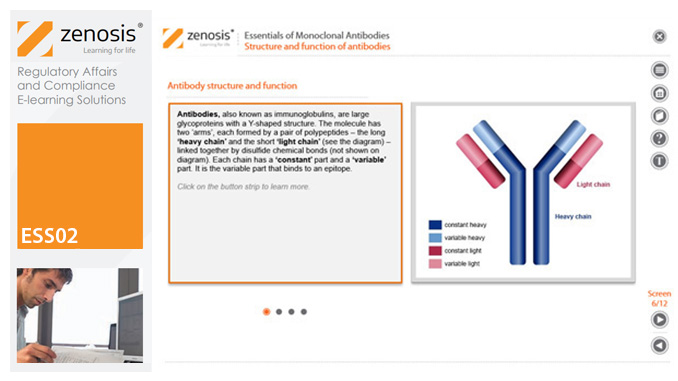

ESS02: Essentials of Monoclonal Antibodies

By Zenosis

This module will introduce you to monoclonal antibodies, explaining how they work, how they are made, and the many uses to which they are put.

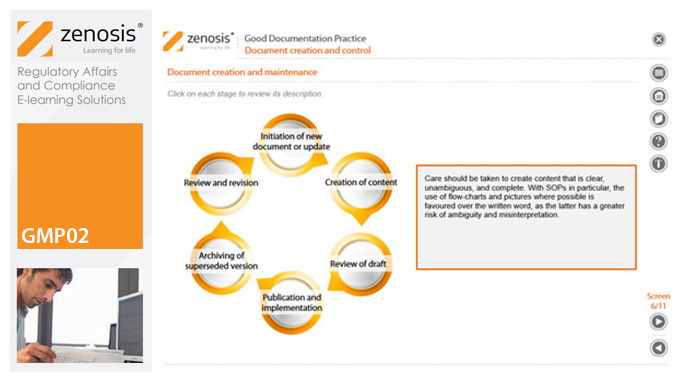

GMP02: Good Documentation Practice

By Zenosis

Good Manufacturing Practice (GMP) for medicinal products relies on documentation. Good Documentation Practice (GDocP) is that part of GMP that applies to the creation, maintenance, use, and retention of documents to provide assurance of the quality of products.

GMP05: Good Manufacturing Practice in Processing Medicinal Products

By Zenosis

Operations in the dispensary and on processing lines are at the heart of medicinal product manufacturing. This module describes how to carry out such operations in compliance with the requirements of Good Manufacturing Practice.

Nursing and Midwifery With Complete Career Guide Course Overview Nursing and midwifery are two of the most respected and rewarding professions in healthcare. This course offers a detailed guide to help you understand the essentials of these vital roles, from the basics of patient care to the complexities of supporting women during pregnancy and childbirth. Whether you’re aiming to pursue a career in nursing or midwifery, or simply wish to broaden your understanding of the field, this course provides valuable insights. As healthcare evolves, the need for skilled professionals in these fields continues to rise, with many exciting opportunities available both in the UK and internationally. This course is designed to offer you a complete overview of nursing and midwifery, covering key topics such as patient care principles, medical ethics, and the role of midwives in modern healthcare systems. By the end of the course, you'll have a strong foundation in both disciplines, preparing you for various career opportunities. Whether you aspire to work in hospitals, clinics, or community settings, this course will equip you with the knowledge you need to confidently navigate the nursing and midwifery sectors, while also understanding the latest trends and challenges within the healthcare industry. ________________________________________________________________________ Key Features: CPD Certified Nursing and Midwifery With Complete Career Guide 10 Instant e-certificate and hard copy dispatch by next working day Fully online, interactive course with audio voiceover Developed by qualified professionals in the field Self-paced learning and laptop, tablet, smartphone-friendly 24/7 Learning Assistance Discounts on bulk purchases Course Curriculum: Nursing Module 01: Introduction to Nursing Module 02: Working in Different Healthcare Settings Module 03: Legal, Standards and Professional Aspects of Ethical Practice: Part - 1 Module 04: Legal, Standards and Professional Aspects of Ethical Practice: Part - 2 Module 05: Effective Communication in Nursing Module 06: Health and Safety in Nursing Module 07: Hygiene in Nursing Module 08: Infection Control Module 09: Asepsis in Nursing Module 10: Medication Administration in Nursing Module 11: Understanding the Immune System in Nursing Module 12: Rest and Sleep Management in Nursing Module 13: Mobility and Immobility Issues of Patients in Nursing Module 14: Pain Management for Nurses Module 15: Nutrition in Nursing Module 16: Fluid and Electrolyte Balance Module 17: Assisting with Elimination Module 18: Oxygenation in Nursing Midwifery Module 01: Definition and Origin of Midwifery Module 02: Midwifery as a Career Option Module 03: Midwifery Management and Education Module 04: Midwives' Role in Health and Inequality Module 05: Social, Cultural and Spiritual Context of Childbearing Module 06: Antenatal Care and Screening Module 07: Midwifery Support in Labour: Intrapartum Care Module 08: Induction of labour Module 09: Postnatal Care as a Midwife Module 10: Nurture and Nature: The Healthy Newborn Module 11: Stillbirth, Neonatal Death and Bereavement Module 12: Infant feeding Module 13: Newborn Infection Module 14: Home Birth Module 15: Complementary and Alternative Medicines Applied to Maternity Care Module 16: Pharmacology and Medicines Management Module 17: Bleeding in Pregnancy Module 18: Medical Disorders of Pregnancy Module 19: Pre-term Labour Module 20: Twins and higher-order births Module 21: Care During the Third Stage of Labour Module 22: Terminology and Abbreviations for Midwifery Module 23: Perinatal mental health Module 24: Supporting a Healthy Pregnancy Module 25: Contraception and family planning Module 26: Effective Communication for Midwifery Module 27: Ethics in Midwifery ________________________________________________________________________ Complete Career Guide for Nursing and Midwifery (A to Z) This isn't just a course; it's your ticket to thriving in the sector and your roadmap to the Nursing. In addition to mastering the essentials of Nursing, you'll also gain valuable skills in CV writing, job searching, communication, leadership, and project management. These 9 complementary courses are designed to empower you at every stage of your journey. Stand out in your career, from crafting a winning CV to excelling in interviews. Develop the leadership skills to inspire your team and efficiently manage projects. This holistic approach ensures you're not just job-ready but career-ready. Enrol today, and let's build your success story together in Nursing. Your dream career starts here! List of career guide courses included in Nursing and Midwifery With Complete Career Guide: Course 01: Professional CV Writing and Job Searching Course 02: Communication Skills Training Course 03: Career Development Training Course 04: Time Management Course 05: Returning to Work Training Course 06: Level 3 Diploma in Project Management Course 07: Leadership Skills Course 08: Body Language Course 09: Interview and Recruitment ________________________________________________________________________ Learning Outcomes: Gain foundational knowledge in nursing, including legal and ethical aspects. Develop effective communication skills essential for nursing practice. Acquire expertise in health and safety, infection control, and asepsis. Master medication administration, pain management, and patient mobility techniques. Understand midwifery principles, from antenatal care to postnatal support. Demonstrate proficiency in addressing perinatal mental health and effective communication. ________________________________________________________________________ Accreditation All of our courses, including this Course, are fully accredited, providing you with up-to-date skills and knowledge and helping you to become more competent and effective in your chosen field. Certification Once you've successfully completed your Course, you will immediately be sent your digital certificates. Also, you can have your printed certificate delivered by post (shipping cost £3.99). Our certifications have no expiry dates, although we recommend renewing them every 12 months. Assessment At the end of the courses, there will be an online assessment, which you will need to pass to complete the course. Answers are marked instantly and automatically, allowing you to know straight away whether you have passed. If you haven't, there's no limit on the number of times you can take the final exam. All this is included in the one-time fee you paid for the course itself. CPD 110 CPD hours / points Accredited by CPD Quality Standards Who is this course for? Aspiring nurses and midwives seeking comprehensive theoretical understanding. Healthcare professionals aiming to enhance their knowledge and skills. Individuals considering a career change to nursing or midwifery. Students interested in the healthcare sector without specific practical training. Career path Mental Health Nurse - £24K to 40K/year. Midwife - £25K to 45K/year. Neonatal Nurse - £24K to 38K/year. Healthcare Educator - £28K to 50K/year. Nursing Home Manager - £30K to 50K/year. Certificates 11 CPD Accredited e-Certificates Digital certificate - Included 11 CPD Accredited Hard Copy Certificates Hard copy certificate - Included