- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Swim Skills / HIIT Refresher - CPD (no equipment)

By SWIMSANITY® AQUA HIIT INSTRUCTOR - Online Course Aqua Certification

A CPD course for certified Swimsanity Instructors to refresh their knowledge and skills, with additional swim skill lessons aimed at improving swimming ability & water confidence, through individual swim exercises for the body, legs and arms. About this course 63 lessons Course curriculum Intro Introduction Video This is Swimsanity Swim Skills The key facts: Swimsanity® Swim Skills Teaching Skills Refresher Teaching Skills Verbal instructions and teaching skills Visual teaching skills Safety and Effectiveness Progressions and adaptations Learning Assessment - Teaching HIIT refresher Using Equipment Introduction Video Paddle Setup Paddle preparation Paddle precautions Setup Introduction Video Say hello and meet the class Kick off the session with the health and safety briefing Start with a warm up Watch the participants Learning Assessment - The Start Paddle Drill Refresher Key benefits of paddle exercises Push out and in Sweeping side to side Punching forwards Punching side to side Long arm lift up and push down Biceps and triceps Albatrosses Learning Assessment - Paddle Exercises Swim Arm Drills Introduction Video Swim arms Front crawl arms Breaststroke arms Butterfly arms Leg Swim Drills Introduction Video Kicking Exercises Benefits of Kicking Exercises Front Crawl Legs Breaststroke Legs - What we want to see Butterfly Legs - What we want to see Body Swim Skills (non HIIT) Introduction Video Streamline Body Position - What we want to see Streamline against a wall Streamline Standing Streamline falling into a float Floating Drill 1 - Toe Touch Floating Drill 2 – Tuck Float Floating Drill 3 – Tuck to streamline to tuck Swim Breathing Drills Swimming breathing drill sequence to teach front crawl swimming Front Crawl breathing drill Breast stroke breathing drill Butterfly breathing drill Cool Down Introduction Cool Down Stretches Summary Bibliography Well done for competing the course

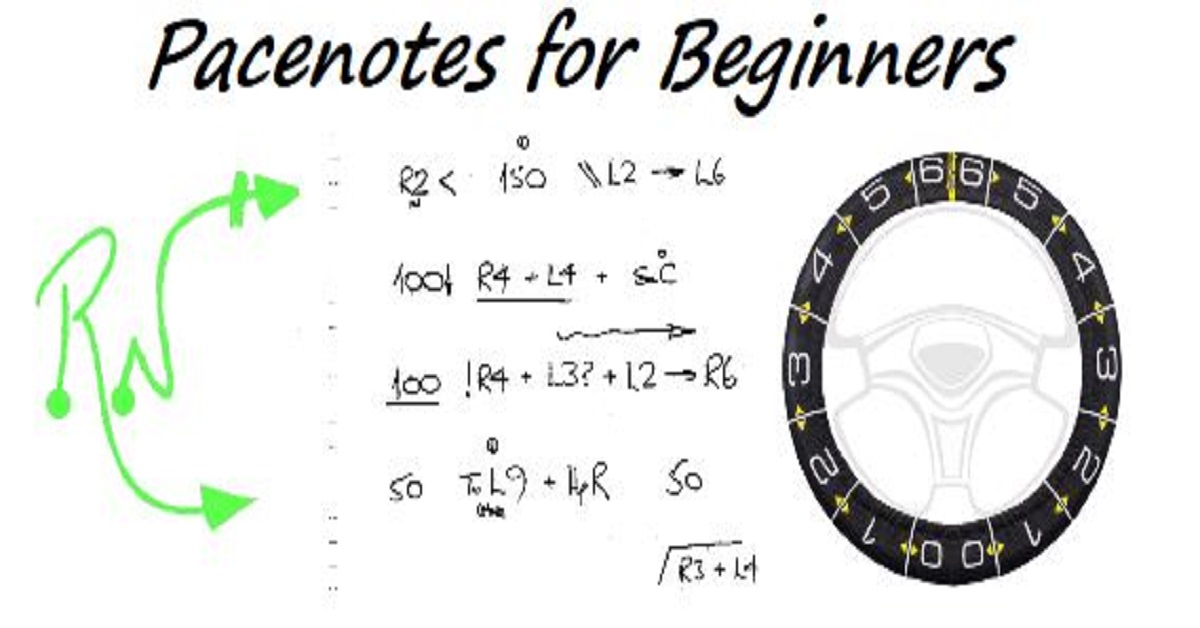

Rally Pacenote Writing for Beginners

By Rally Navigation Training Services

Rally training webinar covering making pace notes for special stage rallying.

Essential GEPON training course description Designed to benefit those requiring an in depth knowledge of the principles and applications of the IEEE Ten Gigabit Ethernet and Gigabit Ethernet Passive Optical Networking and Fibre to the X in NG network applications and their associated equipment, its flexibility and function within a modern transmission network. Using an effective mix of instruction and correlation to theory based learning the delegate will gain a complete understanding of the equipment and the tasks to be undertaken in a real life situation. What will you learn Compare FTTx networks. Compare PON variants. Recognise the GEPON architecture. Explain how GEPON works. Recognise GEPON issues. Essential GEPON training course details Who will benefit: Anyone requiring GEPON knowledge. Prerequisites: Introduction to data communications and networking. Duration 2 days Essential GEPON training course contents FTTN, FTTC, FTTH Single Mode Fibre (SMF) and various types, Multimode Fibre (MMF), Fibre Safety and properties (Dispersion/attenuation), Fibre Reel cables and types, Fibre installation and air blown fibre, Transmitters and receivers - power budget/laser classes, Fibre to the home (FTTH), FTTC (Fibre to the Cabinet), FTTN (Fibre to the node), FTTD (Fibre to the Desk), FFTH Topologies and wavelengths, Active or Passive Optical Network (PON). WDM equipment and GPON OSP design Wavelength considerations, WDM/DWDM/CWDM EDFA optical amplification, AWG (Arrayed Waveguide Grating) splitters, Couplers (splitters) and losses, Optical splitters 1x2, 1x4, 1x8, 1x16, 1x32, 1x64, 2x64. IEEE PON variants Gigabit Ethernet Passive Optical Network (GEPON), Time Division PON (TDM-PON), Wave Division Multiplexing PON (WDM-PON), 1Gbps, 10Gbps, 40Ggps, 100Gbps, Strategies for TDM-PON to WDM-PON migration, Architecture of NG-PON (hybrid WDM/TDM PON), Additional services than triple play. GEPON design GEPON OSP centralized design, GEPON OSP distributed design, GEPON PON splitters x4 x8 x32, Fibre splice trays / fibre cassette trays / fibre enclosures, GEPON field testing /GEPON field installation verification, GEPON physical layer testing, Optical Time Domain Reflectometer (OTDR), Optical power source /Optical power meter, Optical Return Loss (ORL), APON/BPON/GPON/EPON/GEPON/10-GEPON comparison. IEEE 802.3ah GEPON: Ethernet in the first mile IEEE 802.3 options, Optical Ethernet options, Ethernet in the first mile, 1000BASE-LX, 1000BASE-SX, IEEE 802.1Q VLANs, Q-in-Q and MAC-in-MAC. QofS Ethernet TOS and priority methods PCP and DiffServe, Reference model / terminology / architecture, Example of ONT functional blocks, Example of OLT functional blocks, FTTx scenarios, The four switching arrangements for external access network backup. IEEE 802.3av 10-GEPON Physical layer, 10GBASE-SR, 10GBASE-LX4, 10GBASE-ER, 10GBASE-LR, 10GBASESW, 10GBASE-LW, 10GBASE-EW, Enhancement band, Bit rate and wavelengths, Compatibility, Forward error correction. IEEE 802.3ca 25G, 50G and 100G NG-EPON MAC frame structure, Downstream multiplexing / Upstream multiplexing, Media access control and ONU registration, Alarm messages. IEEE 802.3bk extended EPON Laser Types PRX40 and PR40, Reference model. GEPON issues and standards GEPON components OLT / GEPON ONT and examples GEPON management, RG (Residential Gateway), HPNA (Home Phone Network Alliance), Power Line Carrier (PLC), GPON DLNI, G.hn or G.9960 MOCA, FTTH Council certification, Standard for network certification, Qualify for use of the fibre-connected home badge, GEPON frame synchronization to network timing, Direct clock synchronization interface (BITS), Multiservice Access Platform (MSAP), Software planning tool. Superconnected cities / voucher scheme. Ethernet OAM Link monitoring, remote failure indication, Remote loopback.

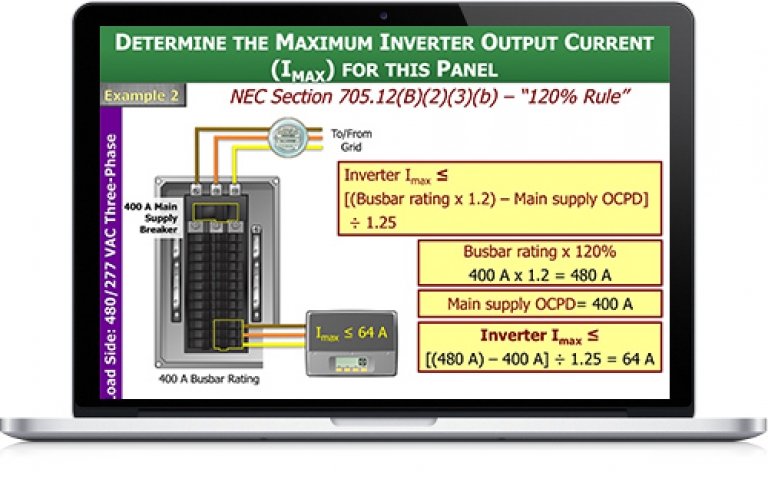

PV202: Solar Training - Advanced PV System Design and the NEC (Grid-Direct)

By Solar Energy International (SEI)

Students who complete PV202 will be able to: Define the purpose of the National Electrical Code (NEC®) and NEC® terminology for PV equipment Determine procedures for proper installation of equipment and conductors, including minimum requirements for working space Examine methods for PV wire management and determine where expansion fittings are required Describe and identify electrical services, including split-phase and three-phase Wye (Y) and Delta (â) Evaluate electrical service details to collect and record during solar site evaluation Identify options for NEC®-compliant PV system interconnection to the utility grid and determine whether a supply side, load side, or additional service connection is appropriate Identify code-compliant methods for connecting an inverter to an existing AC feeder Calculate PV module voltage based on temperature to ensure compatibility with system components and NEC® Section 690.7, and explore other options for maximum PV system DC voltage calculations Identify NEC® requirements and sizing of disconnects and overcurrent protection devices (OCPDs) in grid-direct PV systems Define inverter grounding configurations Evaluate inverter choices and system configurations, including string inverters, central inverters, and module level power electronics (MLPE) Identify requirements for equipment grounding, equipment grounding conductors (EGC), and grounding electrode conductors (GEC), and size the conductors according to the NEC® Identify common causes of ground-faults and arc-faults Describe ground-fault and arc-fault protection devices Describe benefits and appropriate locations of surge protection devices (SPD) Demonstrate the use of sun charts and perform calculations to determine row spacing and minimize inter-row shading Identify how Codes detailing access for first responders impact PV array roof layout Examine fire classifications that affect racking and module selection Detail NEC rapid shutdown requirements and options for implementation Identify load and structural considerations for low- and steep-slope roof-mounted PV systems Calculate wind uplift force and select appropriate lag bolts Review issues related to planning, design, and installation of ground-mount PV arrays Review PV system circuit terminology, definitions, and conductor types Calculate minimum overcurrent protection device (OCPD) size and conductor ampacity using appropriate adjustment and correction factors Calculate voltage drop and verify system operation within acceptable limits Examine requirements for PV system labeling Calculate the maximum and minimum number of modules per PV source circuit, and number of PV source circuits per inverter Determine size of residential grid-direct PV system based on site and customer-specific considerations including the number and wiring layout of modules, conductor and OCPD sizes, and the AC interconnections Determine the size of a large, multiple inverter, grid-direct PV system based on site and customer-specific considerations, including the quantity and layout of modules and inverters and the AC interconnection Define large-scale PV and review associated NEC® allowances and requirements Describe importance of Data Acquisition Systems (DAS) Identify common DAS equipment and hardware Review DAS design, installation, and commissioning processes and common problems associated with DAS Show how reports can be generated and utilized to remotely assess health of system

Materials Management

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course Materials Management is an essential link in the Supply Chain process. It takes an even bigger significance in the Upstream industry when the cost of a rupture in equipment or stock can be tremendous, without even considering the cost of the equipment itself. The downside may result in the accumulation of out-of-commission materials which leads to business inefficiency. What does it take to maintain efficient Materials Management? This 3 full-day course will explain more in detail. This course can also be offered through Virtual Instructor Led Training (VILT) format. Training Objectives At the end of this course, participants will be able to: Understand the importance of an efficient Materials Management in the Supply Chain process Examine the control and validation of Stock processes Understand the role of the Duet and work within the Stock Duet in materials management Learn about the key factors in Stock optimisation Target Audience This course will benefit all personnel involved in Supply Chain including Stock Controllers, Cost Controllers, Buyers, Logisticians and those from the technical department such as Technical Administrators and members of the duet. Course Level Basic or Foundation Trainer Your expert course leader has 25 years of experience in management positions in Contracting, Procurement and Logistics, mainly in the Oil & Gas Industry. He was a Lecturer for IFP Training for 5 years. During his Oil & Gas industry experience, he has worked on major Oil and Gas development projects like the Yadana project in Myanmar, Akpo project in Nigeria and YLNG in Yemen. His international experience allows him to adapt very easily and integrate the multicultural specificities of the Oil & Gas industry in his teaching. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

PVOL202: Solar Training - Advanced PV System Design and the NEC (Grid-Direct) - Online

By Solar Energy International (SEI)

Students who complete PVOL202 will be able to: Define the purpose of the National Electrical Code (NEC®) and NEC® terminology for PV equipment Determine procedures for proper installation of equipment and conductors, including minimum requirements for working space Examine methods for PV wire management and determine where expansion fittings are required Describe and identify electrical services, including split-phase and three-phase Wye (Y) and Delta (â) Evaluate electrical service details to collect and record during solar site evaluation Identify options for NEC®-compliant PV system interconnection to the utility grid and determine whether a supply side, load side, or additional service connection is appropriate Identify code-compliant methods for connecting an inverter to an existing AC feeder Calculate PV module voltage based on temperature to ensure compatibility with system components and NEC® Section 690.7, and explore other options for maximum PV system DC voltage calculations Identify NEC® requirements and sizing of disconnects and overcurrent protection devices (OCPDs) in grid-direct PV systems Define inverter grounding configurations Evaluate inverter choices and system configurations, including string inverters, central inverters, and module level power electronics (MLPE) Identify requirements for equipment grounding, equipment grounding conductors (EGC), and grounding electrode conductors (GEC), and size the conductors according to the NEC® Identify common causes of ground-faults and arc-faults Describe ground-fault and arc-fault protection devices Describe benefits and appropriate locations of surge protection devices (SPD) Demonstrate the use of sun charts and perform calculations to determine row spacing and minimize inter-row shading Identify how Codes detailing access for first responders impact PV array roof layout Examine fire classifications that affect racking and module selection Detail NEC rapid shutdown requirements and options for implementation Identify load and structural considerations for low- and steep-slope roof-mounted PV systems Calculate wind uplift force and select appropriate lag bolts Review issues related to planning, design, and installation of ground-mount PV arrays Review PV system circuit terminology, definitions, and conductor types Calculate minimum overcurrent protection device (OCPD) size and conductor ampacity using appropriate adjustment and correction factors Calculate voltage drop and verify system operation within acceptable limits Examine requirements for PV system labeling Calculate the maximum and minimum number of modules per PV source circuit, and number of PV source circuits per inverter Determine size of residential grid-direct PV system based on site and customer-specific considerations including the number and wiring layout of modules, conductor and OCPD sizes, and the AC interconnections Determine the size of a large, multiple inverter, grid-direct PV system based on site and customer-specific considerations, including the quantity and layout of modules and inverters and the AC interconnection Define large-scale PV and review associated NEC® allowances and requirements Describe importance of Data Acquisition Systems (DAS) Identify common DAS equipment and hardware Review DAS design, installation, and commissioning processes and common problems associated with DAS Show how reports can be generated and utilized to remotely assess health of system

Completion Design

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 5 full-day course is aimed at engineers and supervisors who already have a basic understanding of well construction methods but who would benefit from a more detailed knowledge of completion design. The course will concentrate on the important aspects of completion design and what makes a safe and efficient well. A common thread of practical examples will be used throughout the course in the form of a case study or 'red-thread' exercise. The case study is based around data all taken from a single field where those attending will work through all the basic issues of a completion design. The exercises associated with the case study is performed in the student's own time after each of the formal sessions. However, at the start of the next day, the case study is reviewed and discussed. The whole case study will continue through all sessions, with each element being reviewed at the start of the next session. There is no 'right' answer to the exercise - producing interesting discussions! The purpose of the course is not to go over specific equipment in detail. Teaching methods include presentations, videos, and animations and the case study. The course will cover: Types and configurations of completions The completion design process Inflow performance, skin and formation damage Perforating; selection, deployment and interface with rest of completion Stimulation and impact on completion and flow performance with coverage of modern horizontal multifrac tools Open hole, non-sand control completions including open hole packers and horizontal well clean up Sand control; when do you need it, basic types and selection guidelines. Includes standalone screens, ICDs, various gravel packing techniques, frac packs and expandable screens Tubing sizing, flow estimation and liquid loading Artificial lift; types and selection criteria, interface with drilling, reservoir and facilities. Design of gas lift and ESPs included Production chemistry impacts on completion, prevention and removal (scales, wax, asphaltene, hydrates, and souring) Metallurgy, corrosion, and erosion; metal types and selection of Elastomers and plastics; types and selection of Tubing stress analysis; picking the grade and weight of tubing, plus selection criteria for packers and expansion devices. Interface between tubing stress analysis and casing design Completion equipment; basic types of equipment, reliability and selection criteria for each (tree, safety valve, mandrel, packers, expansion devices etc) Completion installation; importance of wellbore clean-out, function and types of brines, pointers for efficient completion installation Non-conventional wells; types and when / where to use them (multilaterals, smart (intelligent) wells and also SAGD, CO2 sequestration, CBM, etc) Training Objectives By the end of this course, the participants should be able to: Have a good understanding of the completion design process and what makes a good completion design Understand the importance of the installation process (completion running) in the design process Have an appreciation of new and developing completion techniques (intelligent wells) Target Audience This course will benefit engineers and field-based personnel such as completion supervisors and production engineers. It is also suitable for completion vendors, specialists such as chemists and subsurface personnel including geologists, reservoir engineers and petrophysicists. Trainer Your expert course leader has 30 years of oil and gas industry experience. A first class degree in geophysics and a master degree in Petroleum Engineering was a prelude to seven years with BP as a petroleum engineer. He left BP and following a short spell in Camco, jointly founded ICE Energy. After six years of completions and petroleum engineering consultancy and training, ICE Energy merged with TRACS International, where he continued with petroleum and completion engineering studies, leading integrated teams, and developing / delivering training courses for a variety of different clients in diverse world-wide locations. In the last five years, he is independent again - focusing on technical consulting and course delivery. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

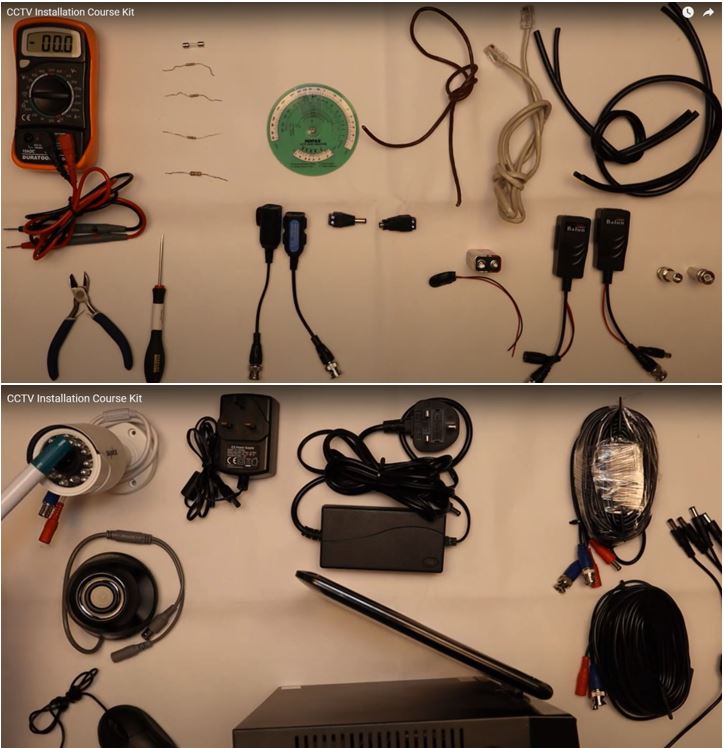

CCTV Installation Course

By Hi-Tech Training

Hi-Tech Training Closed Circuit Television (CCTV) Installation Course is designed to give participants a practical knowledge of the operation and installation of CCTV systems at a foundation level.

Certified Data Centre Facilities Operations Specialist (CDFOS)

By Nexus Human

Duration 3 Days 18 CPD hours This course is intended for The primary audience for this course is anyone who works in and around IT, facilities or data centre operations and needs to understand and improve the daily operations including important processes such as lock-out/tag-out, the right process for installing/de-installing equipment, safety procedures, capacity management and much more. Overview The old believe that a fully redundant data centre facility will save the day is no longer true as many research outcomes have revealed that the majority of downtime is caused by the human factor. Policies, processes, procedures and work instructions should be carefully developed, ideally following relevant standards, to ensure an effcient and effective data centre operations which are also compliant to the required regulations. The CDFOS© (Certified Data Centre Facilities Operations Specialist) course is a three-day course which will enable participants to fully understand the requirements of running the day-to-day operations of a mission critical data centre. Participants will gain all the required competences for running the daily operations, understand which processes should be in place, and the critical elements of those processes and how to execute them. The course is fully aligned with the DCOS© (Data Centre Operations Standard). Data centre facilities operations management have proven to be the key differentiator between a data centre that is performing well or badly. Service Level Management Service Level Management Needs analysis Capability assessment Service portfolio and catalogue Service Level Agreements Reporting - Complaint procedure Customer satisfaction Service Improvement Process (SIP) Safety and Crisis Management Most common type of accidents and why they often happen The roles and responsibilities of appointed safety staff The importance of the OH&S or WHS manual Calibration of measurement and test equipment Proper lock-out/tag-out procedures Emergency response plan requirement for various potential emergencies The importance of Permit To Work Physical Security Standard Operating Procedures (SOP) for security Security risk assessment Security zones Physical inspections / security patrols Delivery of goods / holding area Entry control of individuals Badges and key management Security monitoring Security incident reporting Facilities Maintenance The importance of maintenance Maintenance definitions Maintenance operations procedures (MOP) Service reports Spare management Tools Housekeeping Data Centre Operations Shift handover Walk around duties Service management Release management Configuration management Floor management Equipment life cycle management Monitoring/Reporting/Control Monitoring requirements Facilities monitoring matrix Sensor / alarm point testing and calibration Notification matrix Escalation requirements Reporting Project Management Project management Project organization Project manager Initiation Planning Execution Monitor and control Closing Evaluation / lessons learnt Environmental Sustainability The importance of sustainability Environmental standards Power efficiency indicators Energy saving best practises Water management Sustainable energy usage Governance and Compliance The importance of document management The siz sub-processes of document management Asset management Requirements or asset recording Exam: Certified Data Centre Facilities Operations Specialist (CDFOS©) Certification exams are administered at the end of the course. The exam is a 90-minute closed book exam, with 60 multiple-choice questions. The candidate requires a minimum of 42 correct answers to pass the exam. Online exam results are known immediately and paper-based exam results will be known within one week. Additional course details: Nexus Humans Certified Data Centre Facilities Operations Specialist (CDFOS) training program is a workshop that presents an invigorating mix of sessions, lessons, and masterclasses meticulously crafted to propel your learning expedition forward. This immersive bootcamp-style experience boasts interactive lectures, hands-on labs, and collaborative hackathons, all strategically designed to fortify fundamental concepts. Guided by seasoned coaches, each session offers priceless insights and practical skills crucial for honing your expertise. Whether you're stepping into the realm of professional skills or a seasoned professional, this comprehensive course ensures you're equipped with the knowledge and prowess necessary for success. While we feel this is the best course for the Certified Data Centre Facilities Operations Specialist (CDFOS) course and one of our Top 10 we encourage you to read the course outline to make sure it is the right content for you. Additionally, private sessions, closed classes or dedicated events are available both live online and at our training centres in Dublin and London, as well as at your offices anywhere in the UK, Ireland or across EMEA.

Pumps, Compressors, Turbines & Troubleshooting

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This intermediate to advanced level 3 full-day training course has been designed to provide participants with a detailed and up-to-date overview of the fluid mechanic fundamentals and operating practice of pumps, compressors and gas and steam turbines. Upon the successful completion of this course, participants will have acquired the practical knowledge to enable them not only to choose the correct device for a particular application but also be in a position to resolve many commonly occurring operating problems. Troubleshooting is an important part of this course and will cover the important topics of Machinery Root Cause Failure Analysis (RCFA) together with Vibration Analysis. This course is ideal for those personnel in the oil, gas, petrochemical, chemical, power and other process industries who require a wider and deeper appreciation of pumps, compressors and turbines, including their design, performance and operation. The participants will be taken through an intensive primer of turbo-machinery principles, using the minimum of mathematics, and will learn how to solve the many and varied practical industrial problems that are encountered. The course makes use of an extensive collection of VIDEO material together with case studies and numerical exercises. Training Objectives Upon the successful completion of this course, each participant will be able to: Apply a comprehensive knowledge of pumps, compressors & turbines and troubleshoot rotating equipment in a professional manner Identify the different types of turbomachinery including basic design aspects and highlighted problem areas Minimise compressor work by understanding the processes involved and identifying their efficiency Understand the flow through turbomachines and the corresponding velocity triangles including torque and power calculations Analyse the different types of centrifugal machines including their design, installation, operation, maintenance, re-rate/retrofit, troubleshooting and control Recognise the various beneficial design aspects of turbomachines and understand the crucial process of cavitation Carry out proper methods of device installation, operation, maintenance and troubleshooting Understand and apply the powerful methods of Machinery Root Cause Failure Analysis Understand the various methods of vibration analysis applied to device diagnostics Target Audience This course provides an overview of all significant aspects and considerations of pumps, compressors and turbines for those who are involved in the design, selection, maintenance or troubleshooting of such equipment. This includes maintenance, reliability, integrity, engineering, production and operations managers, engineers and other technical staff. Course Level Intermediate Advanced Trainer Your expert course leader is a Senior Mechanical & Instrumentation Engineer (UK, B. Sc., M.Eng., Ph D) with over 45 years of industrial experience in Process Control & Instrumentation, Pumps, Compressors, Turbines and Control Valve Technology. He is currently a Senior Independent Consultant to various petrochemical industries in the UK, USA, Oman, Kuwait and KSA where he provides consultancy services on both the application and operational constraints of process equipment in the oil & gas industries. During his early career, he held key positions in Rolls Royce (UK) where he was involved in the design of turbine blading for jet engines, subject to pre-specified distributions of pressure. During this period and since, he has also been closely involved in various aspects of Turbomachinery, Thermodynamics and Fluid Mechanics where he has become a recognised authority in these areas. Later, he joined the academic staff of University of Liverpool in the UK as a Professor in Mechanical Engineering Courses. A substantial part of his work has been concerned with detailed aspects of Flowmetering - both of single & multiphase flows. He has supervised doctoral research students in this area in collaboration with various European flowmeter manufacturers. He joined Haward Technology Middle East in 2002 and was later appointed as European Manager (a post which has since lapsed) and has delivered over 150 training courses in Flowmeasurement (single- and multi-phase), Control, Heat Exchangers, Pumps, Turbines, Compressors, Valve and Valve Selection as well as other topics throughout the UK, USA, Oman and Kuwait. During the last two years, he has delivered courses with other training companies operating in the Far and Middle East. He has published about 150 papers in various Engineering Journals and International Conferences and has contributed to textbooks on the topics listed above. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations