- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

Central Heating Controls Wiring and Fault Finding

By Technique Learning Solutions

The Central Heating Controls Wiring and Fault Finding course is a two day-day short course aimed at anyone involved in the construction, commissioning, inspection & testing or maintenance of central heating electrical control systems. The Central Heating Controls Wiring and Fault Finding course covers all the commonly used control systems in use today and is focused on the ‘practical’ construction and commissioning along with the relevant fault finding techniques. The Central Heating Controls Wiring and Fault Finding course requires an understanding of electrical principles and cable termination skills. A requirement of this course is the successful completion of their Essential Electrics examination prior to sitting the central heating controls wiring & fault finding examinations. Please ring if clarification is needed on this point. There are two 20 minute open book examinations and the associated practical assessments. A third examination and associated assessment will be required for candidates not holding the Essential Electrics unit. The Central Heating Controls Wiring and Fault Finding course comprises of: Short theory sessions introducing the conventional wiring systems, ‘Y’ Plan, ‘S’ Plan, ‘C’ Plan, Etc. Detailed practical workshop sessions, undertaking the construction, testing and commissioning of systems Fault finding and maintenance tasks performed on working systems Examination and practical assessment preparation ready for the assessments Evaluation of the system control function (why and how it works) Each student will work on their own system, and will have plenty of time to absorb and understand how each systemworks. Advise will be given on suitable ‘tooling’ and test equipment. These are nationally recognizable qualifications which are fast becoming an essential requirement for this type of work. The course costs include comprehensive course notes and examination entry fees.

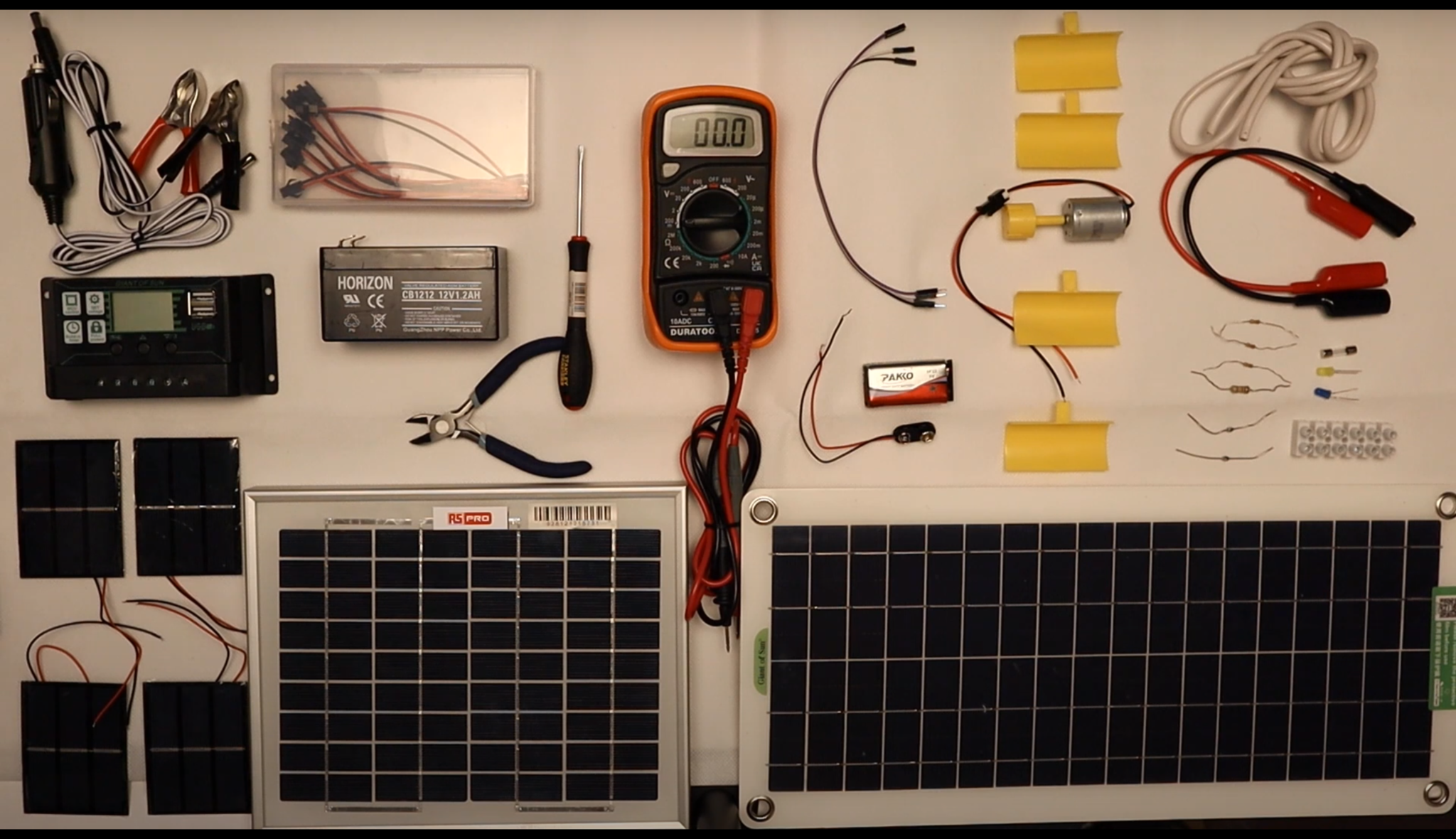

Alternative Energy Technology Course

By Hi-Tech Training

The Alternative Energy Technology Course is a practically based alternative energy course designed to give participants an understanding of alternative energy options and provide them with that practical knowledge and skills to build solar to electric and wind to electric systems at a foundation level. The course is designed to be of benefit to people either working or intending to work as:- Alternative Energy Installers or anyone just wishing to gain practical knowledge of Practical Alternative Energy Systems

PV201LW: Solar Training - Women's Solar Electric Lab Week (Grid-Direct)

By Solar Energy International (SEI)

Students who complete the PV201L workshop will be able to: Perform power and energy calculations Obtain and apply specifications for PV modules and determine their performance given various environmental and operating conditions Safely operate various types of digital multimeters Diagram and determine the power, current, and voltage characteristics of PV modules in different series and parallel configurations Install various mounting systems (ground, pole, roof, and trackers). Decipher balance-of-system equipment specification sheets to determine the critical information needed for system design Install a residential grid-direct system including the array, inverter, circuit conductors, and overcurrent protection Safely operate equipment grounding, system grounding, and components and conductors used for grounding Work with wires and components on schematics of residential grid-direct systems: disconnects, inverter, equipment grounding conductors, ungrounded conductors, grounded conductors, the grounding electrode(s), and the AC and DC system grounds Identify potential safety hazards and demonstrate the proper use of personal protective equipment for working on grid-direct PV systems List the order of installation, commissioning, and decommissioning of a grid-direct PV system Note: This class is a great complement to PV301L, the Solar Electric Lab Week (Battery-Based). This Women's Solar Electric Lab Week is powered by:

Subsea Control Systems & Umbilicals

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This course will provide detailed learning to the various aspects of the design, analysis and operation of subsea control systems for a variety of field development options to allow effective management of subsea facilities either from offshore structures or from shore bases. This will include power and telemetry focussing on electrical, hydraulic and electro-hydraulic systems, shut down systems, and application of intelligent monitoring and 'smart' fields. Training Objectives By attending this course, participants will be able to: To provide detailed knowledge and understanding of the requirements for, and design of, subsea electrical, electro-hydraulic, hydraulic and programmable control systems. Knowledge of the components and uses of a wide variety of subsea control systems the requirements for and design implications, of umbilicals and control lines (power and telemetry) Knowledge of, and ability to model, power requirements subsea and detailed understanding of the requirements and objectives of pre-commissioning, both at the factory and in situ. Knowledge of the standards involved in design of equipment, control and application of manual and automatic shut-down valves, and emergency response systems Introduction to design of redundancy and the role of spare capacity and to be able to put this knowledge to effect to contribute to detailed field design. An understanding of obsolescence management in subsea control systems Target Audience This course is intended for Offshore and Onshore Subsea Production Control Systems; Engineers, Technicians, Supervisors, Operators; Graduates; Apprentices; transfers from other industries, and existing staff with a limited exposure to Production Control and a need to understand the more technical aspects of the system. Companies not directly involved in the day-to-day support of the industry, but occasionally involved in supplying and supporting operators; manufacturers and suppliers of Oil and Gas equipment and services may also find this a useful course to understand how their equipment and technical expertise is integrated into the Offshore system. Trainer For most of his working life, your expert course leader has been in a role that has enabled him to pass on skills and knowledge to others. A full-time role in Training and Development came about in 1996 with the offer to take up a full-time teaching post at Aberdeen College. In 1998, he was recruited by Kvaerner Oilfield Products, an Oil & Gas industry company, specialising in Subsea Control Systems, to develop and implement a Training & Competence program acceptable for its staff of over 600 and their client companies - a challenge he could not resist. In 2003, he broadened his horizons and became an independent Training & Development consultant. Building a reputation for delivering training and development to the Oil & Gas industry to the highest standards, he later joined Jee Ltd, a leading subsea engineering and training company based in Aberdeen. He was tasked with a wide portfolio of training, coaching & mentoring to achieve high levels of competence for the client's staff and customers. He is also a Science and Engineering Ambassador (Scotland), promoting the need for engineers and technicians for Scotland's industries, a frequent consultant to the European Economic & Social Committee for standardising Vocational Skills training and competence throughout the EU. He holds memberships in the Society of Operations Engineers, Chartered Institute of Personnel & Development and Society of Underwater Technologies. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

HV & MV Power System Design, Protection & Coordination - Virtual Instructor-Led Training (VILT)

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your expertise in HV/MV power system design and protection coordination with EnergyEdge's virtual instructor-led training. Join now!

HV & MV Power System Design, Protection & Coordination - Virtual Instructor-Led Training (VILT)

By EnergyEdge - Training for a Sustainable Energy Future

Enhance your expertise in HV/MV power system design and protection coordination with EnergyEdge's virtual instructor-led training. Join now!

Gas Conditioning and Processing

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This 3 full-day course covers the design of systems for natural gas handling and treatment from the wellhead to the gas processing plant to achieve marketable products that meet desired product specifications. This course will emphasize on field handling equipment and separation systems, dehydration, fluid measurement, sampling and analysis as well as introduction into reciprocating and centrifugal compressors. It will comprise interactive presentations including exercises/quizzes. This course can also be offered through Virtual Instructor Led Training (VILT) format. Training Objectives At the end of the course, the participants will be able to describe and explain the following: Gas processing principles of dehydration (water removal) by absorption, adsorption, refrigeration and low temperature separation (JT effect) and basic associated equipment Gas processing in-depth by absorption using glycol and glycol proper (Pre- Cooling requirements, Dew Point control and related processes). Glycol regeneration including principles of stripping, DRIZO and Coldfinger. Process equipment involved for water removal by absorption. (Knock out drums; Contactor - absorber and internals, heat exchangers, re-boilers, pumps, filters and glycol storage). Principles of gas metering and types of meter (Measurement Units (MJ, BTU, nM3, scf and conversions). Typical gas contracts & sales specifications. Gas pipeline operations. Target Audience Production and processing personnel involved with natural gas and associated liquids to acquaint or reacquaint themselves with gas conditioning and processing unit operations. This course is for production operations engineers, operations field supervisors, facility engineers, process engineers, design engineers, operations personnel and others who select, design, install, evaluate or operate gas processing plants and related facilities. Course Level Intermediate Trainer Your expert course leader has more than 25 years of accumulated experience in the Oil & Gas Industry, particularly in LNG / Offshore LNG Industry as Project Manager (8 years) and Process Technology Design (12 years). From 2010 to 2012, he worked for TOTAL E&P as Manager of R&D activities related to LNG, FLNG, Gas Treatment and Safety Engineering. From 1992 to 2010, he worked for Technip, spending 12 years (1992 to 2004) in the Process and Technology Division, where he was the Principal Engineer on gas treatment and LNG projects such as Yemen LNG and Nigeria LNG. From 2004 to 2010, he was actively involved in the development of Technip Offshore LNG technologies as Project Manager - several patents filed, author or co-author of different publications on LNG transfer technologies. He has also been a member of: the Foreign Advisory Committee on the 2nd Trondheim Technology Gas Conference, Norway, 2-3 November 2011 the Steering Committee on the SPE Forum 'Economic and Sustainability Challenges in the Future Development of Sour Gas', Bali, Indonesia, 8-13 May 2011 The Technip 'Experts Network' as 'Main Expert - LNG' for several years He holds a 'summa cum laude' master's degree in Chemical Engineering from Rome University 'La apienza' (1992) and has been a member of the Italian Register of Engineers. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

Certified Data Center Facilities Operations Manager (CDFOM)

By Nexus Human

Duration 3 Days 18 CPD hours This course is intended for The primary audience for this course is someone who works, or has ambition to work, in a leadership role in data center operations such as a data center facilities manager, data center operations manager, who has the responsibility to achieve and improve the high-availability and manageability of the data center operations. Overview After completion of the course the participant will be able to: Perform the needs analysis translating business requirements to data center services Set-up and manage the data center operations team Implement and monitor safety- and security practices Identify a suitable maintenance program for the data center facility and its equipment Select the appropriate policies and procedures required for data center operations Monitor the data center availability, capacity and capability Manage and implement basic data center projects Set-up and implement an environmental sustainability program Select an appropriate back-up site to support organizational resilience Identify and respond to risk in the data center Manage and support the document life cycle Create a basic budget proposal Select and manage vendors and measure their performance Manage data center assets Managing the facilities of today?s high-end and high-availability data centers is an extremely demanding and complex task which is often underestimated. There is often very little appreciation and understanding of the complexities of managing today's mission-critical data centers where downtime is not an option, especially since many of the data centers are operating at, or near, their design limits. Operations management at the facilities layer makes all the difference. Even a data center designed to the highest redundancy level as per the ANSI/TIA-942 standard could still experience many unscheduled downtime events due to poor planning, operations, maintenance and management processes. Service Level Management Service Level Management Needs analysis Capability assessment Service portfolio Service catalogue Service Level Agreements (SLAs) Availability measurement Data points in SLA Service reporting Complaint procedure Customer satisfaction measurement Service Improvement Process (SIP) SLA content The Data Center Organization Operational issues Organization chart Roles and responsibilities Skills matrix Contingency / backup roles Shift management Performance management Career development Training and assessment Job rotation Succession planning Disciplinary program Managing Safety & Statutory Requirements Safety policies and regulations Occupational Health and Safety (OH&S) Safety awareness training Permit to Work (PTW) Lock-out / Tag-out Personal Protective Equipment (PPE) Testing and tagging of equipment Emergency preparedness and response Reporting of safety issues Reviews / internal audit / external audit Managing Physical Security Security policies and procedures Security standards and guidelines Security staff Security awareness Security incident management Disciplinary program Reviews, internal and external audits Facilities Management Maintenance policies and procedures Various maintenance programs Outsourcing of maintenance activities Maintenance contract options Warranty Maintenance schedule Service situations Spart part management Contamination control Data Center Operations Policies and procedures for data center operations Service operations and the daily data center operations Monitoring / Reporting / Control Monitoring requirements Escalation procedures Reporting Trend analysis Reviews Project Management Project management Project organization Project manager Project phases Environment Sustainability The importance of sustainability Sustainability policies Environmental management Power efficiency indicators - Waste management - Water management ICT utilisation management Environmental performance measurements Renewable energy factor (REF) Organizational Resilience Business continuity Data center facility options Business Impact Analysis Type of facility Human resources Facility, equipment and consumables Governance, Risk and Compliance Management commitment Coordination, collaboration and integration Compliance Risk management Document management Financial management Vendor management Asset management Additional course details: Nexus Humans Certified Data Center Facilities Operations Manager (CDFOM) training program is a workshop that presents an invigorating mix of sessions, lessons, and masterclasses meticulously crafted to propel your learning expedition forward. This immersive bootcamp-style experience boasts interactive lectures, hands-on labs, and collaborative hackathons, all strategically designed to fortify fundamental concepts. Guided by seasoned coaches, each session offers priceless insights and practical skills crucial for honing your expertise. Whether you're stepping into the realm of professional skills or a seasoned professional, this comprehensive course ensures you're equipped with the knowledge and prowess necessary for success. While we feel this is the best course for the Certified Data Center Facilities Operations Manager (CDFOM) course and one of our Top 10 we encourage you to read the course outline to make sure it is the right content for you. Additionally, private sessions, closed classes or dedicated events are available both live online and at our training centres in Dublin and London, as well as at your offices anywhere in the UK, Ireland or across EMEA.

STATUTORY SURVEYOR AND FLAG STATE INSPECTOR

By Lloyd's Maritime Institute

CLASS SURVEYOR ADVANCED CERTIFICATE PROGRAM is CPD ACCREDITED ✔️- The course content is aimed at providing newly appointed surveyors and those as yet limited practical experience with solid technical knowledge about classification and statutory matters and thus allows participants to obtain "work-ready" knowledge. The training program is specifically structured for those looking to taking up the role of a Non-exclusive surveyor enabling them to properly undertake the duty imposed under the relevant Classification rules, it is intended to facilitate access to the knowledge and skills demanded by increasingly sophisticated maritime technology while meeting the requirements of: - Mandatory parts of the code for Recognized Organizations (IMO RO Code) and IMO Resolution A.1120(30), - IACS Proc Req. 2009/Rev.2 2019, - ISO 9001:2015, - ISO/IEC 17020:2012 standards.

CPRI training course description This course is designed to give the delegate a technical overview of the CPRI protocols and link setup. We will explain the industry cooperation to define the key internal interface between the radio equipment control (REC) and the radio equipment (RE). Also explained will be the SAP that the CPRI link supports for IQ Interface, frame synchronisation, link control and management and the master and slave ports. We will investigate the CPRI block diagram and together with the data formats and sample mapping solutions. The CPRI frame hierarchy and hyperframe construction will be detailed during this three day overview course. What will you learn Explain the CPRI Block diagram. Understand hyperframing capabilities. Explain the CPRI frame format. Understand how the synchronisation is compliant with 3GPP & WiMAX requirements. Understand the two electrical characteristics of CPRI standard. Understand the CPRI standards structure. Understand the CPRI system & Interface definitions. List the four standard bit rates of the CPRI specification. Understand the CPRI Protocol stacks. CPRI training course details Who will benefit: Anyone looking for a technical overview of the CPRI protocols and link set up. Prerequisites: None. Duration 3 days CPRI training course contents System Description Subsystems. Nodes. Protocol layers. Protocol data planes. User data planes. Antenna carriers. Service Access Points (SAP). Link. Passive Link. Hop. Multi-hop Connection. Logical Connection. Master Port & Slave Port. System Architecture Basic System Architecture & Common Public Radio Interface Definition. System Architecture with a link between Res. Reference configurations: Chain topology, Tree topology, Ring topology. RECs & REs in both chain & tree topology Functional description Radio Functionality. Functional Decomposition between REC and RE: For UTRA FDD, For WiMAX & E-UTRA, For GSM. CPRI Control Functionality. Interface Baseline Interface Specification. Protocol Overview. IQ Data. Synchronisation. L1 Inband Protocol. C & M Data. Protocol Extensions. Vendor Specific Information. Physical Layer Specifications Line Bit Rate. Physical Layer Modes. Electrical Interface. Optical Interface. Line Coding. Bit Error Correction/Detection. Frame Structure. Mapping Methods. Container Blocks. Hyperframes. GSM, UMTS & WiMAX Timing. Link Delay Accuracy & Cable Delay Calibration. Link Maintenance Data Link Layer (Layer 2) Specification Layer 2 Framing for Fast & Slow C & M Channels. Medium Access Control/Data Mapping. Flow Control. Start-up Sequence General. Layer 1 Start-up Timer. State Description. Transition Description. Interoperability Reserved Bandwidth. Version Numbers. Supplementary Specification Details Delay Calibration Example. Reference Test Points. List of Abbreviations & Gloss