- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

3861 Courses in Cardiff delivered Live Online

LNG Terminal Operations & Safety

By EnergyEdge - Training for a Sustainable Energy Future

Elevate your expertise in LNG terminal operations safety through our classroom training course. Energyedge provides industry-leading expertise and guidance.

Project Stakeholder Relationship Skills: Virtual In-House Training

By IIL Europe Ltd

Project Stakeholder Relationship Skills: Virtual In-House Training This course is designed to provide project managers with the ability to: Analyze the complexities of major stakeholder relationship categories Apply the most appropriate interpersonal relationship skills to the different categories of relationships Align the dynamic needs of the stakeholders with a project's objective throughout the project life cycle What you Will Learn Examine traditional and non-traditional ways to identify and assess stakeholders Explain how competence, character, and trust lead to project success and strong relationships with stakeholders Utilize 'Embodied Leadership' skills to build stakeholder relationships Apply stakeholder engagement best practices to case study and real-life scenarios Getting Started Stakeholders and project success Stakeholder management research Managing stakeholder relationships Identifying Stakeholders Stakeholder categories Stakeholder relationships across the project life cycle Tools and techniques for identifying stakeholders Assessing Stakeholders Assessing stakeholder relationships Recognizing stakeholder attitudes toward the project Analyzing stakeholders Using other types of stakeholder assessments Building Stakeholder Relationships The importance of psychological safety Building trust and getting results The anatomy of trust Navigating Challenging Situations Dynamics of conflict Responding to conflict Managing difficult conversations

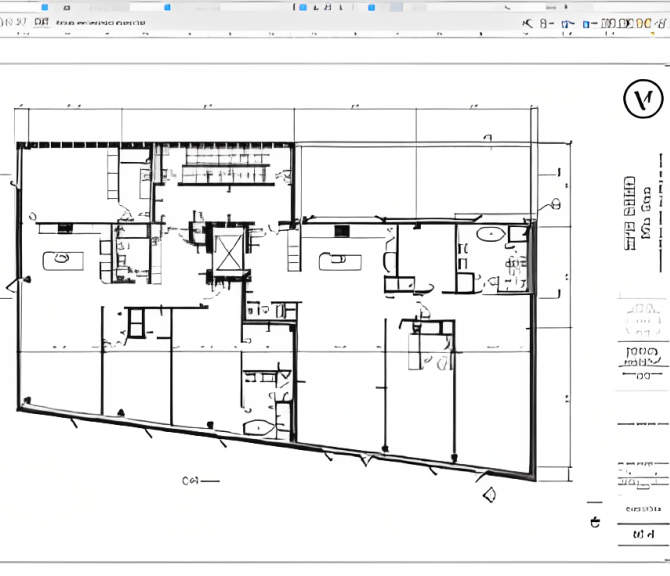

Vectorworks Evening Training

By London Design Training Courses

Why choose Vectorworks Evening Training Course? Course Link. This course led by certified expert, this course offers flexibility for evening learning. Choose in-person or live online sessions to master Vectorworks in architecture, interior design, and landscaping. Enroll now even after business hours! Duration: 10 hrs. Method: 1-on-1, Personalized attention. Schedule: Tailor your own schedule by pre-booking a convenient hour of your choice, available from Mon to Sat between 9 am and 7 pm. The Vectorworks course provides comprehensive training in computer-aided design (CAD) and Building Information Modeling (BIM) using the powerful Vectorworks software. This hands-on, instructor-led course covers 2D drafting, technical drawing, and 3D modeling, enabling participants to apply Vectorworks effectively in real-world projects. Key Features: Hands-on, instructor-led classroom training. Practical Vectorworks CAD projects for real-world application. Part-time evening or weekend options available. 1-2-1 Private learning experience. Module 1: Grasping CAD and Vectorworks Understanding the Role of CAD in Design Getting Acquainted with Vectorworks Software Module 2: Configuring Your Workspace Customizing Your Workspace Essential Options and Preferences Module 3: Mastering Foundational Drawing Skills Techniques for Drawing Object Selection Methods Module 4: Advanced Object Manipulation Merging Shapes Reflecting Objects Rotating Objects Grouping Elements Module 5: Precision Drawing and Scaling Techniques Working with Scale Setting Preferences for Accuracy Creating and Saving Templates Module 6: Achieving Accurate Object Placement Ensuring Drawing Precision Precise Object Movement Module 7: Advanced Editing Methods Utilizing Fillet Tool Applying Offset Function Module 8: Understanding Object Attributes and Groups Basic Attribute Management Editing Object Groups Module 9: Object Duplication Techniques Linear Duplicates Rectangular Duplicates Circular Duplicates Module 10: Crafting Room Plans Designing Walls Incorporating Windows and Doors Module 11: Development of Room Plans Methods for Room Plan Drawing Module 12: Exploring Additional Attributes Hatch Patterns Gradients Image Fills Module 13: Creating Elevation Drawings Elevation Drawing Techniques Effective Approaches Module 14: Importing Images for Graphic Use Graphic Illustration Integrating Images Module 15: Symbols and Resource Handling Symbol Creation Introduction to Resource Browser Module 16: Organizing Drawings Using Design Layers Optimizing Design Layer Utilization Module 17: Labeling Drawings and Title Blocks Drawing Labels Title Block Text Placement Module 18: Plotting and Printing Methods User Interface Navigation and Terminology Printing Approaches Module 19: Generating Drawing Sheets A1, A2, and A3 Sheet Formats Module 20: Utilizing Viewports Effectively Managing Multiple Views Module 21: Professional Model Presentation Techniques Paper Space Presentation Conversion to PDF Formats Module 22: File and Project Management Module 23: Object Display and Terminology Module 24: Objects and Data Management Module 25: Precise Object Placement Object Snapping Quick Selection Module 26: Dividing and Measuring Objects Module 27: Dimensioning and Annotations Module 28: Working with Text Elements Module 29: Customizing Tool Palettes Module 30: Organizing Tool Palettes Module 31: Efficient Tool Palette Usage Module 32: Standard Views and Drawing Techniques Module 33: Drawing Curved Shapes Arcs, Donuts, and Ellipses Drawing Module 34: Real-World Units and Measurements Module 35: Object Manipulation Adjusting Object Angles Module 36: File Handling and Management Saving, Exiting, and Opening Projects Module 37: Creating Mirrored Images Module 38: Introduction to 3D Modeling By the end of the Vectorworks Evening Training Course, participants will: Demonstrate proficiency in using the Vectorworks interface, tools, and navigation. Create and edit 2D drawings, including walls, doors, windows, floors, ceilings, stairs, and railings. Effectively manage layers, classes, and views for organized and controlled object placement. Create and edit dimensions and annotations for accurate measurements and documentation. Develop skills in creating, modifying, and utilizing symbols for increased efficiency. Generate and edit 3D geometry, apply textures, and create sections and elevations from 3D models. Create polished presentation drawings using viewports, annotations, and text for clarity. Summarize course content and confidently apply learned skills in Vectorworks projects. Utilize available resources for further learning and professional development.

FPSO Operations Management & Safety

By EnergyEdge - Training for a Sustainable Energy Future

About this Training Course This five-day training course will cover aspects of FPSO operations with an emphasis on management of safety. A background of the methodology used to generate the various safety plans and codes used in the operational safety case will be covered. The course will also review general operational guidelines in the offshore environment to ensure that the operations are completed as designed. This will include offtake operations and maintenance processes for the plant and vessel as well as a session on subsea. Training Objectives To enable participants to obtain an in-depth understanding of FPSO operations, safety and maintenance: Provide a broad overview of how an FPSO operation is set up and established in the field Grasp the various methods used to moor the production units Analyse information and methods required to establish the operation according to local and international regulations. Assess the methods used to calculate the safety parameters and requirements to construct an approved valid safety case Explore conditions to monitor during operations with regards to safety and structure Inspect various types of hazards associated with production and produced materials Review regular and emergency operational maintenance requirements Examine cyclones and weather events causing disconnection Comprehend manning, training requirements and operations including cargo Case studies and Exercises: The training course uses real life examples and case studies to explain the setup, preparation, implementation and operational activities required to successfully complete FPSO operations from a safety and maintenance perspective. This will allow the application of participants' newly-acquired knowledge. Case studies also stimulate independent thinking and discussion among the participants. Case Studies The case studies proposed for this course will include: A group exercise to consider what is the minimum requirement for the production of a safety case Generic plan for the development of a maintenance management system using computer software systems (e.g. Amos) Construction of a UWILD plan to include scope and potential tendering requirements Quizzes The various quizzes can be expanded or arranged to suit the group/interests and topics covered but will generally include the following topics: Mooring types and location where they are primarily used Safety cases Safety management systems Process hazards and mitigation UWILD components and regulations Operations management Offtake operations Target Audience The course is generally aimed at personnel who are involved in FPSO operations as either offshore crew or onshore support team members. This course will also greatly benefit the following groups but not limited to: Process engineers Surveyors Facility engineers Naval architects Operations engineer Health, Safety, Environment (HSE) specialists and managers Maintenance engineers Course Level Intermediate Training Methods The training course is presented in an interactive workshop format that allows for discussion. The course will be delivered through analysis of case studies and running examples of problems. Course Duration: 5 days in total (35 hours) The training instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all the topics covered. The training comprises of information supplemented by visual activities including photographs from various operations and videos of operational and safety activities. Interaction verbally will be necessary to achieve the best learning outcome from the materials. Course timings and breaks 0830 - Registration 0900 - Start of training 1030 - Morning break 1045 - Training recommences 1230 - Lunch break 1330 - Training recommences 1515 - Afternoon break 1530 - Training recommences 1700 - End of training Trainer Your expert course leader has been involved in the Oil and Gas industry for over 28 years in several different roles commencing as a second deck officer on FPSO's and moving through the industry from deck officer to Master, OIM and Field Superintendent. He has also been in charge of semisubmersible and fixed production platforms as field superintendent before moving ashore into senior management roles. On completion of industry specific activities, he moved to teaching roles at South Tyneside Maritime College in the department of marine and simulation and presented live courses to maritime students from cadet to Master. Prior to returning to Perth in March 2019, he was training manager for a subsidiary of Gaz Transport and Technigaz of France. He has a Master Class 1 certificate with endorsements for hazardous cargoes and a Graduate Certificate in Business Administration as well as multiple course certificates required to operate FPSO's, platforms and semisubmersible facilities. He has been involved in the preparation of national standards for Safety Cases (Australia); Designing and structural setup of competency-based training systems in South East Asia. He was also involved in the development of minimum standards, competency profiles position based and preparation and implementation of training plans to ensure competency in the local staff in Asian operations. He was part of the development team for minimum standards of offshore safety in Australian offshore operations including the implementation of the Common Safety Training Program (CSTP). He was also involved in implementing training plans for both simulator and classroom based courses in LNG operations and cargo tank design and construction. Highlighted work experience: Premier Petroleum Myanmar Ltd Petronas Carigali Newfield Australia (Cartier) Pty Ltd: FPSO Jabiru Venture FPSO Challis Venture Onshore OIM Australian FPSO Management Pty. Ltd. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Gas Turbines, Co-Generation and Combined Cycle Power Plants

By EnergyEdge - Training for a Sustainable Energy Future

About this training course This 5 full-day course will cover all aspects of gas turbines, co-generation and combined cycle power plants. It will cover in detail all the components of these types of power plants such as: compressors, gas and steam turbines, heat recovery steam generators, deaerators, condensers, lubricating systems, instrumentation, control systems, and economics. The design, selection considerations, operation, maintenance, pay-back period, economics of co-generation plants and combined cycles, as well as, emission limits, reliability, monitoring and governing systems are also covered in detail. This course will also provide up-dated information in respect to all the significant improvements that have been made to co-generation and combined cycles power plants, during the last two decades. The course will illustrate through sophisticated computer simulation how gas turbines, co-generation and combined cycle plants perform under steady-state and transient conditions. In addition, the participants will learn how to use the computer simulation program which provides the following benefits: Allow the operator to extend the gas turbine operating period by avoiding unnecessary outages and maintenance activities. Determination of essential gas turbine maintenance activities to reduce the duration of outages. Profit optimization of co-generation and combined cycle plants. Minimization of the environmental emissions of co-generation and combined cycle plants. Training Objectives Power Plant Computer simulation: Gain a thorough understanding of computer simulation of gas turbines, co-generation, and combined cycle plants. Power Plant Components and Systems: Learn about all components and subsystems of the various types of power plants such as gas turbines, co-generation and combined cycle plants Power Plants Economics: Examine the advantages, applications, performance and economics of power plants such as: gas turbines, co-generation, and combined cycle plants Power Plant Equipment: Learn about various power plant equipment including: compressors, turbines, governing systems, combustors, deaerators, feed water heaters, etc. Power Plant Maintenance: Learn all the maintenance activities required for power plants such as: gas turbines, co-generation plants and combined cycles to minimize their operating cost and maximize their efficiency, reliability, and longevity Power Plant Environmental Emissions: Learn about the monitoring and control of environmental emissions. Power Plant Instrumentation and Control Systems: Learn about the latest instrumentation and control systems of gas turbines, co-generation and combined cycles power plants Power Plant Reliability and Testing: Increase your knowledge of power plant predictive and preventive maintenance, reliability and testing. Power Plant Selection and Applications: Gain a detailed understanding of the selection considerations and applications of power plants such as: gas turbines, co-generation and combined-cycle power plants Power Plant Profitability: Learn about the reliability, life cycle cost, profitability, refurbishment, and life extension methods for gas turbines, co-generation and combined cycle power plants. Target Audience Engineers of all disciplines Managers Technicians Maintenance personnel Other technical individuals Course Level Basic or Foundation Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: 'POWER GENERATION HANDBOOK' second edition, published by McGraw-Hill in 2012 (800 pages) Practical manual (500 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Debian training course description This three day hands on course provides a comprehensive coverage of core Linux administration tasks on Debian Linux. What will you learn Administer & configure Linux systems. Maintain Linux by handling disk space and taking regular backups. Manage software packages. Perform basic troubleshooting. Maintain a secure Linux system. Describe the organisation and implementation of the filesystem. Debian training course details Who will benefit: System administrators. Network administrators. Prerequisites: Linux fundamentals Duration 3 days Debian training course contents Managing software Package Concepts, RPM, rpm Commands, Yum, Dependencies and Conflicts, Startup Script Problems, Shared Libraries, Library Management, Managing Processes, the Kernel: The First Process, Process Lists, Foreground & Background Processes, Process Priorities, Killing Processes. Configuring hardware Configuring Firmware and Hardware, IRQs, I/O Addresses, DMA Addresses, Boot Disks, Coldplug and Hotplug Devices, Configuring Expansion Cards and PCI Cards, Kernel Modules, USB Devices, Linux USB Drivers, Configuring Hard Disks, Partitioning Systems, LVM, Common Layouts, Creating Partitions and Filesystems, Maintaining Filesystem Health, Tuning, Journals, Checking Filesystems, Monitoring Disk Use, Mounting and Unmounting Filesystems. Managing files File Management Commands, File Naming and Wildcards, File Archiving, Links, Directory Commands, File Ownership and Group, File access control, Permissions, chmod, Defaults, File Attributes, Disk Quotas, Enabling and setting Quotas, Locating Files, The FHS. Booting Linux and editing files Installing Boot Loaders, GRUB Legacy, GRUB 2, Alternative Boot Loaders, the Boot Process, Boot Messages, Runlevels and the Initialization Process, Runlevel Functions, Runlevel Services, Alternative Boot Systems , Upstart, system. Administering the system Managing Users and Groups, Tuning User and System Environments, Using System Log Files, Understanding syslogd , Setting Logging Options, Manually Logging Data, Rotating Log Files, Reviewing Log File Contents, Maintaining the System Time, Linux Time Concepts, Manually Setting the Time, Using NTP, Running Jobs in the Future, Understanding the Role of cron, Creating System cron Jobs, Creating User cron Jobs, Using anacron, Using at. Configuring basic networking TCP/IP, Network Hardware, Network Addresses, Hostnames, Network Ports, Configuring Linux for a Local Network, Configuring with DHCP, Static IP Address, Configuring Routing, Using GUI Configuration Tools, ifup and ifdown, Diagnosing Network Connections, Testing Connectivity, Tracing a Route, Checking Network Status , Examining Network Traffic, Additional Tools. Securing your systems Administering Network Security, Super Server Restrictions, Disabling Unused Servers, Administering Local Security, Securing Passwords, Limiting root Access, Setting Login, Process, SUID/SGID Files, Configuring SSH, Using GPG, Generating, Importing and Revoking Keys, Encrypting and Decrypting Data, Signing Messages and Verifying Signatures.

Ubuntu training course description This three day hands on course provides a comprehensive coverage of core Linux administration tasks on Ubuntu Linux. What will you learn Administer & configure Linux systems. Maintain Linux by handling disk space and taking regular backups. Manage software packages. Perform basic troubleshooting. Maintain a secure Linux system. Describe the organisation and implementation of the filesystem. Ubuntu training course details Who will benefit: System administrators. Network administrators. Prerequisites: Linux fundamentals Duration 3 days Ubuntu training course contents Managing software Package Concepts, RPM, rpm Commands, Yum, Dependencies and Conflicts, Startup Script Problems, Shared Libraries, Library Management, Managing Processes, the Kernel: The First Process, Process Lists, Foreground & Background Processes, Process Priorities, Killing Processes. Configuring hardware Configuring Firmware and Hardware, IRQs, I/O Addresses, DMA Addresses, Boot Disks, Coldplug and Hotplug Devices, Configuring Expansion Cards and PCI Cards, Kernel Modules, USB Devices, Linux USB Drivers, Configuring Hard Disks, Partitioning Systems, LVM, Common Layouts, Creating Partitions and Filesystems, Maintaining Filesystem Health, Tuning, Journals, Checking Filesystems, Monitoring Disk Use, Mounting and Unmounting Filesystems. Managing files File Management Commands, File Naming and Wildcards, File Archiving, Links, Directory Commands, File Ownership and Group, File access control, Permissions, chmod, Defaults, File Attributes, Disk Quotas, Enabling and setting Quotas, Locating Files, The FHS. Booting Linux and editing files Installing Boot Loaders, GRUB Legacy, GRUB 2, Alternative Boot Loaders, the Boot Process, Boot Messages, Runlevels and the Initialization Process, Runlevel Functions, Runlevel Services, Alternative Boot Systems , Upstart, system. Administering the system Managing Users and Groups, Tuning User and System Environments, Using System Log Files, Understanding syslogd , Setting Logging Options, Manually Logging Data, Rotating Log Files, Reviewing Log File Contents, Maintaining the System Time, Linux Time Concepts, Manually Setting the Time, Using NTP, Running Jobs in the Future, Understanding the Role of cron, Creating System cron Jobs, Creating User cron Jobs, Using anacron, Using at. Configuring basic networking TCP/IP, Network Hardware, Network Addresses, Hostnames, Network Ports, Configuring Linux for a Local Network, Configuring with DHCP, Static IP Address, Configuring Routing, Using GUI Configuration Tools, ifup and ifdown, Diagnosing Network Connections, Testing Connectivity, Tracing a Route, Checking Network Status , Examining Network Traffic, Additional Tools. Securing your systems Administering Network Security, Super Server Restrictions, Disabling Unused Servers, Administering Local Security, Securing Passwords, Limiting root Access, Setting Login, Process, SUID/SGID Files, Configuring SSH, Using GPG, Generating, Importing and Revoking Keys, Encrypting and Decrypting Data, Signing Messages and Verifying Signatures.

Suse training course description This three day hands on course provides a comprehensive coverage of core Linux administration tasks on Suse Linux. What will you learn Administer & configure Linux systems. Maintain Linux by handling disk space and taking regular backups. Manage software packages. Perform basic troubleshooting. Maintain a secure Linux system. Describe the organisation and implementation of the filesystem. Suse training course details Who will benefit: System administrators. Network administrators. Prerequisites: Linux fundamentals Duration 3 days Suse training course contents Managing software Package Concepts, RPM, rpm Commands, Yum, Dependencies and Conflicts, Startup Script Problems, Shared Libraries, Library Management, Managing Processes, the Kernel: The First Process, Process Lists, Foreground & Background Processes, Process Priorities, Killing Processes. Configuring hardware Configuring Firmware and Hardware, IRQs, I/O Addresses, DMA Addresses, Boot Disks, Coldplug and Hotplug Devices, Configuring Expansion Cards and PCI Cards, Kernel Modules, USB Devices, Linux USB Drivers, Configuring Hard Disks, Partitioning Systems, LVM, Common Layouts, Creating Partitions and Filesystems, Maintaining Filesystem Health, Tuning, Journals, Checking Filesystems, Monitoring Disk Use, Mounting and Unmounting Filesystems. Managing files File Management Commands, File Naming and Wildcards, File Archiving, Links, Directory Commands, File Ownership and Group, File access control, Permissions, chmod, Defaults, File Attributes, Disk Quotas, Enabling and setting Quotas, Locating Files, The FHS. Booting Linux and editing files Installing Boot Loaders, GRUB Legacy, GRUB 2, Alternative Boot Loaders, the Boot Process, Boot Messages, Runlevels and the Initialization Process, Runlevel Functions, Runlevel Services, Alternative Boot Systems , Upstart, system. Administering the system Managing Users and Groups, Tuning User and System Environments, Using System Log Files, Understanding syslogd , Setting Logging Options, Manually Logging Data, Rotating Log Files, Reviewing Log File Contents, Maintaining the System Time, Linux Time Concepts, Manually Setting the Time, Using NTP, Running Jobs in the Future, Understanding the Role of cron, Creating System cron Jobs, Creating User cron Jobs, Using anacron, Using at. Configuring basic networking TCP/IP, Network Hardware, Network Addresses, Hostnames, Network Ports, Configuring Linux for a Local Network, Configuring with DHCP, Static IP Address, Configuring Routing, Using GUI Configuration Tools, ifup and ifdown, Diagnosing Network Connections, Testing Connectivity, Tracing a Route, Checking Network Status , Examining Network Traffic, Additional Tools. Securing your systems Administering Network Security, Super Server Restrictions, Disabling Unused Servers, Administering Local Security, Securing Passwords, Limiting root Access, Setting Login, Process, SUID/SGID Files, Configuring SSH, Using GPG, Generating, Importing and Revoking Keys, Encrypting and Decrypting Data, Signing Messages and Verifying Signatures.

CentOS training course description This three day hands on course provides a comprehensive coverage of core Linux administration tasks on CentOS Linux. What will you learn Administer & configure Linux systems. Maintain Linux by handling disk space and taking regular backups. Manage software packages. Perform basic troubleshooting. Maintain a secure Linux system. Describe the organisation and implementation of the filesystem. CentOS training course details Who will benefit: System administrators. Network administrators. Prerequisites: Linux fundamentals Duration 3 days CentOS training course contents Managing software Package Concepts, RPM, rpm Commands, Yum, Dependencies and Conflicts, Startup Script Problems, Shared Libraries, Library Management, Managing Processes, the Kernel: The First Process, Process Lists, Foreground & Background Processes, Process Priorities, Killing Processes. Configuring hardware Configuring Firmware and Hardware, IRQs, I/O Addresses, DMA Addresses, Boot Disks, Coldplug and Hotplug Devices, Configuring Expansion Cards and PCI Cards, Kernel Modules, USB Devices, Linux USB Drivers, Configuring Hard Disks, Partitioning Systems, LVM, Common Layouts, Creating Partitions and Filesystems, Maintaining Filesystem Health, Tuning, Journals, Checking Filesystems, Monitoring Disk Use, Mounting and Unmounting Filesystems. Managing files File Management Commands, File Naming and Wildcards, File Archiving, Links, Directory Commands, File Ownership and Group, File access control, Permissions, chmod, Defaults, File Attributes, Disk Quotas, Enabling and setting Quotas, Locating Files, The FHS. Booting Linux and editing files Installing Boot Loaders, GRUB Legacy, GRUB 2, Alternative Boot Loaders, the Boot Process, Boot Messages, Runlevels and the Initialization Process, Runlevel Functions, Runlevel Services, Alternative Boot Systems , Upstart, system. Administering the system Managing Users and Groups, Tuning User and System Environments, Using System Log Files, Understanding syslogd , Setting Logging Options, Manually Logging Data, Rotating Log Files, Reviewing Log File Contents, Maintaining the System Time, Linux Time Concepts, Manually Setting the Time, Using NTP, Running Jobs in the Future, Understanding the Role of cron, Creating System cron Jobs, Creating User cron Jobs, Using anacron, Using at. Configuring basic networking TCP/IP, Network Hardware, Network Addresses, Hostnames, Network Ports, Configuring Linux for a Local Network, Configuring with DHCP, Static IP Address, Configuring Routing, Using GUI Configuration Tools, ifup and ifdown, Diagnosing Network Connections, Testing Connectivity, Tracing a Route, Checking Network Status , Examining Network Traffic, Additional Tools. Securing your systems Administering Network Security, Super Server Restrictions, Disabling Unused Servers, Administering Local Security, Securing Passwords, Limiting root Access, Setting Login, Process, SUID/SGID Files, Configuring SSH, Using GPG, Generating, Importing and Revoking Keys, Encrypting and Decrypting Data, Signing Messages and Verifying Signatures.