- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

71 Courses in Cardiff delivered Live Online

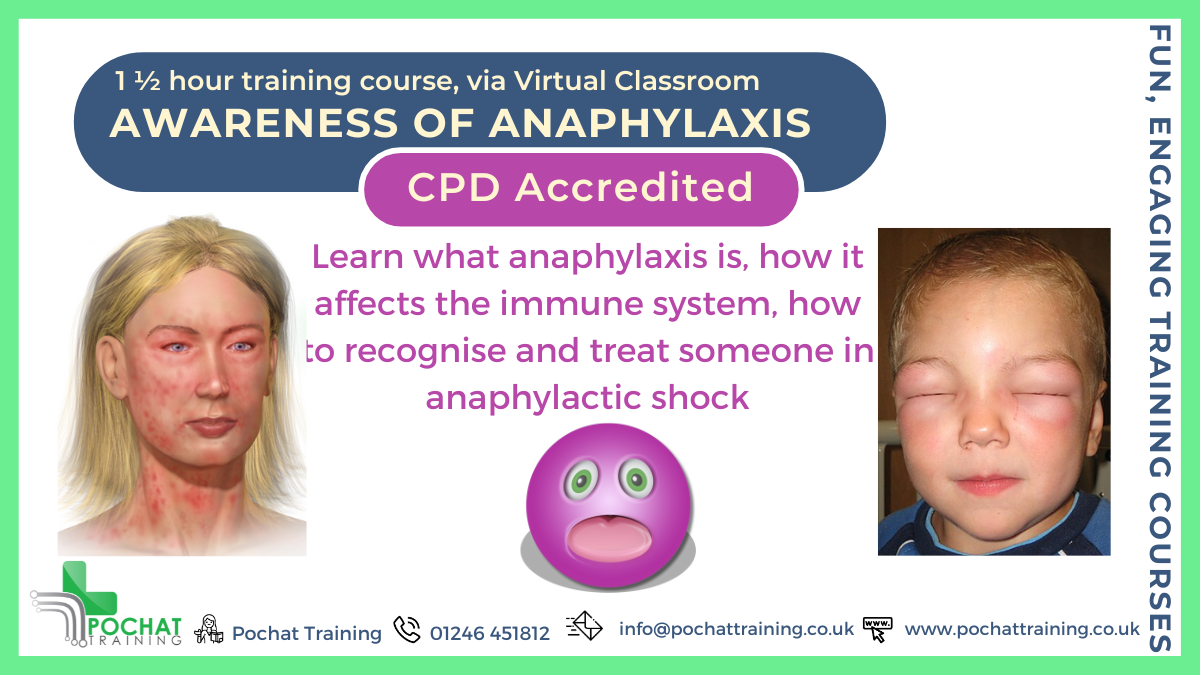

CPD Accredited, Interactive Short Course 1½ hr session Would you know how to save someone's life if they were to go into anaphylactic shock? Learn how to do so from the comfort of your own home or workplace Course Contents: What is anaphylaxis The causes of anaphylaxis The immune system How to recognise someone in anaphylactic shock How to treat someone in anaphylactic shock Benefits of this Short Course: Allergy is the most common chronic disease in Europe The UK has some of the highest prevalence rates of allergic conditions in the world, with over 20% of the population affected by one or more allergic disorder A staggering 44% of British adults now suffer from at least one allergy and the number of sufferers is on the rise Up to 20% of patients with allergies struggle daily with the fear of a possible asthma attack, anaphylactic shock, or even death from an allergic reaction Almost a third of allergy sufferers have had to chance their lifestyles to reduce their allergic reactions In 2014, 19.2% of emergency admissions were for anaphylactic reactions and 19.2% were for ‘Other’ allergic reactions With the knowledge you'll pick up from this course, you could potentially save someone's life! Your browser does not support HTML5 video.

Online Communication Monitoring

By Technique Learning Solutions

This course explains what a Health, Safety and Environment Management System (HSEMS) is, and why it is important. It also introduces Safety Culture and discusses the basic fundamentals of incident investigation and analysis. The course analyses what is meant by communication and consultation, explains why and how HSE performance monitoring is carried out and finally, describes what a Safety Case is, the potential benefits of developing a Safety Case, how to put one together and how to make good use of it.

Care Home Legionella Responsible Person Course (3 to 4h CPD)

By The First Principle Group Ltd

SEO Description: Elevate the standard of health and safety in your care home with our comprehensive 3-hour CPD Care Home Legionella Management Course. Specifically crafted for care home professionals, this online course empowers facility managers, maintenance teams, and health and safety officers with essential skills and knowledge to manage legionella risks effectively. Aligned with HSE ACOP L8 guidelines, the course offers in-depth learning about prevention, assessment, and control of legionella in care environments. Gain a CPD Certificate upon completion, showcasing your commitment to upholding the highest standards in care home safety. Join our expert-led live sessions for a practical and engaging learning experience, ensuring your care home remains a safe and compliant haven for residents and staff.

COSHH & RIDDOR

By Prima Cura Training

This course aims to provide a more in depth understanding of COSHH & RIDDOR.

Root Cause Analysis (RCA) is used to analyse the root causes of focus events with both positive and negative outcomes, but it is most commonly used for the analysis of failures and incidents. Causes for such events can be varied in nature, including design processes and techniques, organizational characteristics, human aspects and external events. RCA can be used for investigating the causes of non-conformances in quality (and other) management systems as well as for failure analysis, for example in maintenance or equipment testing.

COSHH & RIDDOR

By Prima Cura Training

This course is designed to provide delegates with awareness in the Control of Substances Hazardous to Health (COSHH) and how it may affect them, their colleagues, and their employer.

QA Level 2 Award In Health And Safety In The Workplace (RQF) Health and Safety Training Courses QA Level 2 Award In Health And Safety In The Workplace (RQF) Course Contents: Roles and responsibilities of employers and employees Health and safety laws Risk assessments and risk control hierarchy Identifying and controlling risks from common workplace hazards, including: Slips, Trips and Falls Manual Handling Fire Working from Height Electricity Hazardous Substances Workplace conditions Ergonomics Equipment Noise and vibration Transport and vehicles Violence Smoking, alcohol and drugs Stress Procedures for responding to accidents and incidents Recording incidents, accidents and ill health Benefits of this course: In 2023/24, 1.7 million people suffered from a work-related illness 600,000 sustained a non-fatal injury 138 People lost their lives 776,000 Workers suffered from work-related stress, depression or anxiety The estimated cost of injuries and ill health last year was £21.6 billion 33.7 million working days, or 140,417 working years, were lost due to work-related illnesses and injuries It is an employer's duty to protect the health, safety and welfare of their employees and other people who might be affected by their business. This includes providing sufficient information, instruction and training of employees, so they can work in a way that does not put themselves or others at risk This QA Level 2 Award in Health and Safety in the Workplace (RQF) course helps employees gain an understanding of health and safety issues and their own role within that Accredited, Ofqual regulated qualification: This Health and Safety Training Course is a nationally recognised, Ofqual regulated qualification accredited by Qualsafe Awards. This means that you can be rest assured that your Health and Safety Certificate fulfils the legal requirements and is an excellent way to make sure you and your employees are trained in Health and Safety. The Ofqual Register number for this course is 603/2687/6

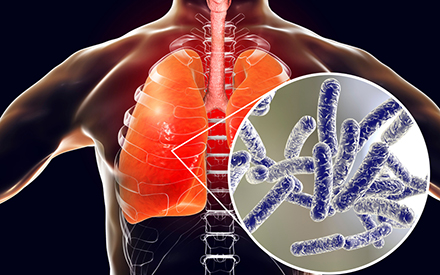

Legionella Responsible Person Course

By Airborne Environmental Consultants Ltd

Legionella Responsible Person is suitable for any persons wanting to gain an understanding of Legionella and how to prevent or control the risk of exposure to Legionella bacteria.

Legionella Responsible Person Course Online

By Airborne Environmental Consultants Ltd

Legionella Responsible Person Online is suitable for any persons wanting to gain an understanding of Legionella and how to prevent or control the risk of exposure to Legionella bacteria.