- Professional Development

- Medicine & Nursing

- Arts & Crafts

- Health & Wellbeing

- Personal Development

NPORS Plant Mover Training Provide candidates with the training and knowledge to enable them to carry out the movement of plant equipment safely. NPORS Plant Mover Training course is aimed at people who are responsible for moving the machinery around the site, this could be maintenance staff or drivers who deliver the machinery to site. All staff should be trained in the safe operation of plant or machinery. NPORS is an approved CSCS Partner Card Scheme, providing evidence that individuals working on construction sites have the appropriate training and qualifications for safe movement of construction machinery. Furthermore, Plant Mover training criteria is based on the approved standards of the Construction Leadership Council. Book with Confidence at Vally Plant Training At Vally Plant Training, we guarantee unbeatable value with our Price Match Promise. When you choose us, you can book with confidence, knowing that we will not be beaten on price. If you find a lower price for the same NPORS Experienced Worker Test, we’ll match it—ensuring you receive top-quality training at the best possible rate. Your skills, our commitment—always at the best price. Course Content Have a basic understanding of the industry, the dangers of working in the industry and their responsibilities as an operator. Have a working knowledge of the manufacturer‘s handbook for each machine. Be able to locate and identify the major components of the machine and explain their functions. Be able to locate and identify all controls and operate the machine safely. Conduct all pre-operational checks in accordance with the manufacturer‘s recommendations. Use the correct PPE for Plant Movers. Prepare machinery for movement and operate machinery safely in forward and reverse gears over varying terrain. Conduct all necessary safety checks in the working area. Correct Storage and transportation of machinery attachments (buckets, forks, breakers etc). Carry out all end of shift and shut down procedures. Variations: Lifting equipment Earthmoving equipment Accessing Equipment Plant Mover Training Available 7 days a week to suit your business requirements. VPT have a team of friendly and approachable instructors, who have a wealth of knowledge of plant movers and the construction industry We have our own training centre conveniently located close to the M5 junction 9, In Tewkesbury. With its own purpose-built practical training area to simulate an actual working environment for the movement of plant Our Plant Mover training and test packages are priced to be competitive. Discounts are available for multiple bookings We can send a fully qualified NPORS Plant Mover Tester to your site nationwide, to reduce the amount of time away from work Frequently Asked Questions 1. What qualifications do I need to enroll in the Plant Mover Training course? The course is intended for individuals who have some prior training or extensive experience with plant moving. If unsure, it’s advised to contact the training center for specific eligibility requirements. 2. What does the Plant Mover Training include? The training covers industry basics, safety responsibilities, machine operations, pre-operational checks, and correct use of personal protective equipment. It includes both theoretical and practical sessions to ensure comprehensive learning. 3. How long does the course last, and what are the class sizes? The course duration varies: 2 days for novices with a maximum of 6 candidates, and 1 day for experienced workers with a maximum of 8 candidates. 4. Are there any certifications provided after completing the course? Yes, successful candidates receive an NPORS card, which is a recognized certification for operating plant machinery safely. The type of card (traditional or with CSCS logo) depends on the specific requirements met during the course. 5. Can I take this course at my workplace? Yes, the training center offers options to conduct training at your site nationwide, though additional charges for mileage and accommodation may apply. 6. Is there funding available for this training? CITB funding might be available for eligible candidates, which can help cover the cost of the training. More courses: Polish your abilities with our dedicated Lift Supervision Training, Slinger Signaller Training, Telehandler Training, Cat & Genny Training, Plant Loader Securer, Ride-On Road Roller, Abrasive Wheel Training, Lorry Loader Training and Scissor Lift Training sessions. Learn the safe and effective operation of these vital machines, crucial for construction and maintenance tasks. Elevate your skills and career prospects by enrolling in our comprehensive courses today. For those looking for a “NPORS Scissor Lift Training near me,” our widespread operations make it convenient for you to access Vally Plant Trainings top-quality training no matter where you are in the UK

Overview Explore trading and hedging applications of barrier options across interest rate, FX, and equity markets. Who the course is for Executives of listed companies who want to enhance their knowledge and skills in ESG and sustainability. Corporate professionals who want to integrate ESG initiatives into their organizations and improve their ESG programs. ESG professionals who want to gain a deep understanding of ESG frameworks, reporting standards, and best practices Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

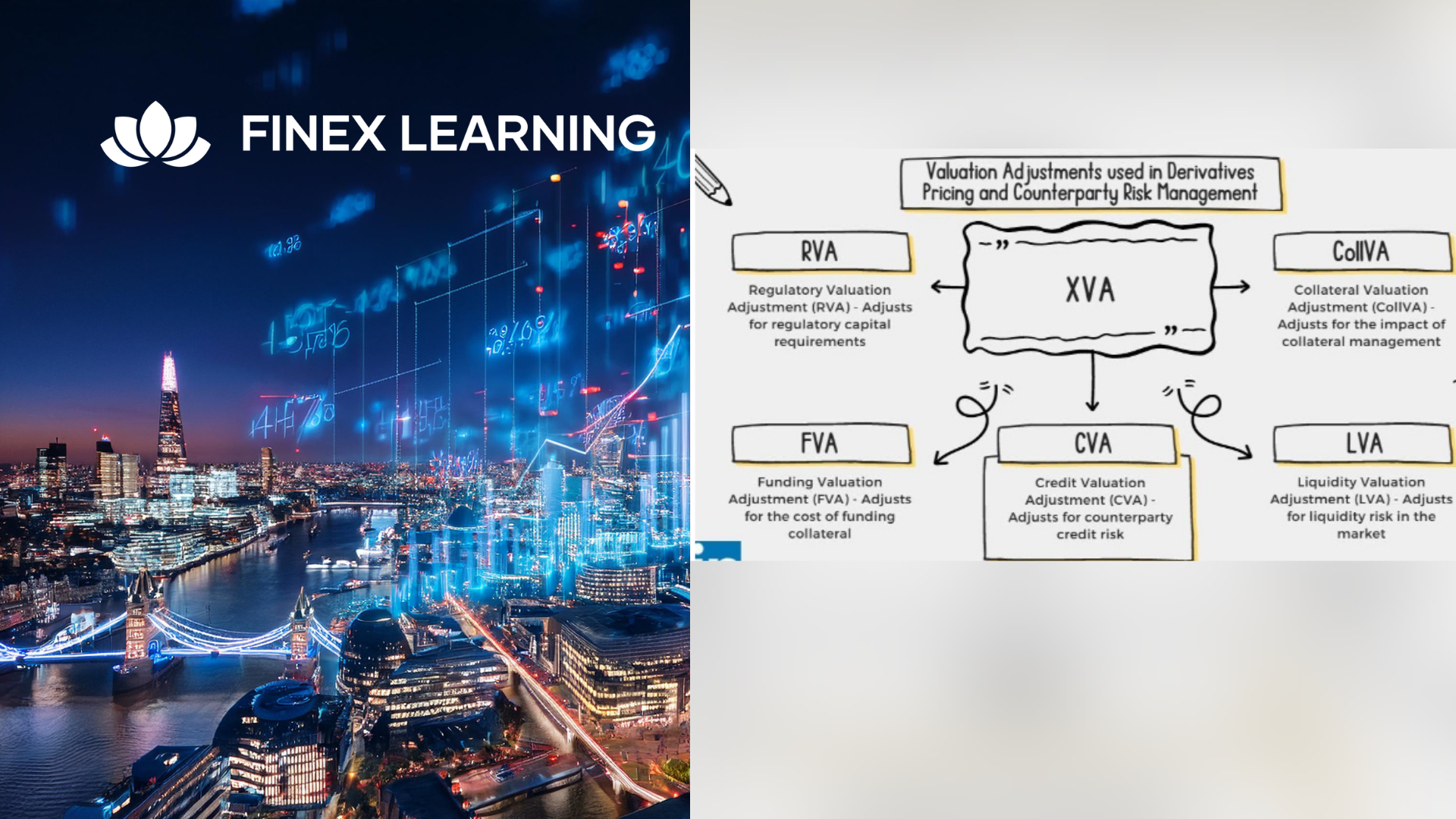

Overview This is a 2 day applied course on XVA for anyone interested in going beyond merely a conceptual understanding of XVA and wants practical examples of Monte Carlo simulation of market risk factors to create exposure distributions and profiles for derivatives used for XVA pricing Learn how to do Monte Carlo simulation of key market risk factors across major asset classes to create exposure distributions and profiles (with and without collateral) for derivatives used for XVA pricing. Learn how to calculate each XVA. Learn sensitivities of each XVA and how XVA desks manage these. Learn regulatory capital treatment of counterparty credit risk (both for CCR and CVA volatility) and how to stress test this within ICAAP or system-wide external, supervisor-led capital stress test. Who the course is for Anyone involved in OTC derivatives XVA traders XVA quants Derivatives traders and salespeople Risk management Treasury staff Internal audit and finance Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

Overview A 1-day course on inflation-linked bonds and derivatives, focusing on the UK market in particular. We examine how inflation is defined and quantified, the choice of index (RPI vs. CPI), and the most common cash flow structures for index-linked securities. We look in detail at Index-linked Gilts, distinguishing between the old-style and new-style quotation conventions, and how to calculate the implied breakeven rate. Corporate bond market in the UK, and in particular the role of LPI in driving pension fund activity. Inflation swaps and other derivatives, looking at the mechanics, applications and pricing of inflation swaps and caps/floors. The convexity adjustment for Y-o-Y swaps is derived intuitively. Who the course is for Front-office sales Product control Research Traders Risk managers Fund managers Project finance and structured finance practitioners Accountants, auditors, consultants Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

Overview This course covers distressed debt analysis and investing, focusing primarily on corporates but also including financial institutions and sovereign debt as special topics. The programme begins with the foundations of the distressed debt market, causes of and early warning signals, possible outcomes and how to evaluate the probability of outcomes in different scenarios. Restructuring is reviewed in detail, as well as estimation of sustainable debt levels, business valuation and the importance of capital and group structure. Differences between active control and passive non-control investments are highlighted, including stakeholder tactics and due diligence. Case studies cover a variety of companies across sectors and geographies, challenging delegates to make investment decisions on real distressed debt situations. Who the course is for Distressed debt investors, Loan portfolio managers and Private equity investors Hedge fund managers High yield credit analysts and Equity analysts High yield asset managers and Mergers and acquisitions bankers Debt capital markets/leveraged finance bankers Business turnaround/restructuring accountants/corporate finance professionals Lawyers Strategy consultants Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

Smartphone video production

By Rough House Media

Do you use video as a tool to promote your charity, business, organisation or campaigns? And if you don’t, do you feel as if you ought to? Videos account for more than 80% of all consumer internet traffic. So the pressure to use video as a marketing and PR tool has increased enormously. But the cost can be prohibitive. Using a video production company, such as ours, might be ideal, but for many it is out of reach – particularly if, like many of our clients, you’re a charity. However, there is an alternative, which more and more organisations are choosing, especially those which need to produce regular digital content. That is to produce the video yourself. Nowadays, you do not even need to invest in a video camera. All you need is your smart phone, some simple equipment you can buy on Amazon for as little as £80, plus your laptop or PC. This is why we have developed a new smartphone video training course, Smart Video. Our smartphone video training course covers: Equipment – including setting up your phone, microphones, tripods and editing programmes Planning your video Techniques to give your films broadcast-quality polish Getting the perfect shot – including shot sizes, positioning the camera, framing, lighting, sound, sequences and backgrounds Filming interviews An introduction to editing Producing videos for social media Bespoke training The course can be tailored to the type of videos you need to make. If most of your videos will be interviews, we’ll focus on presenting your interviewee in the best possible light – literally. If, on the other hand, you need to film buildings, events or products, we’ll tailor the course accordingly. If your video needs a script, we’ll give you tips and techniques on how to “write to pictures”, so your messages comes across well. And on all our courses, we’ll give you a guide to the best equipment and apps to use to enhance your filming and editing. The smartphone video course will be led by Paul Curran who has many years experience producing, filming and editing films and videos, for the BBC and corporate clients.

Overview This is a 2 day course on understanding credit markets converting credit derivatives, from plain vanilla credit default swaps through to structured credit derivatives involving correlation products such as nth to default baskets, index tranches, synthetic collateralized debt obligations and more. Gain insights into the corporate credit market dynamics, including the role of ratings agencies and the ratings process. Delve into the credit triangle, relating credit spreads to default probability (PD), exposure (EAD), and expected recovery (LGD). Learn about CDS indices (iTRAXX and CDX), their mechanics, sub-indices, tranching, correlation, and the motivation for tranched products. The course also includes counterparty risk in derivatives market where you learn how to managed and price Counterparty Credit Risk using real-world, practical examples Understand key definitions of exposure, including Mark-to-Market (MTM), Expected Exposure (EE), Expected Positive Exposure (EPE), Potential Future Exposure (PFE), Exposure at Default (EAD), and Expected Loss (EL) Explore the role of collateral and netting in managing counterparty risk, including the key features and mechanics of the Credit Support Annex (CSA) Briefly touch upon other XVA adjustments, including Margin Valuation Adjustment (MVA), Capital Valuation Adjustment (KVA), and Collateral Valuation Adjustment (CollVA). Who the course is for Credit traders and salespeople Structurers Asset managers ALM and treasury (Banks and Insurance Companies) Loan portfolio managers Product control, finance and internal audit Risk managers Risk controllers xVA desk IT Regulatory capital and reporting Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

Presentation skills for salespeople (In-House)

By The In House Training Company

We've all sat through far more bad presentations than good ones, but knowing what 'good' looks like is easier than successfully replicating it. Sales presentations are a performance and, as salespeople, fluffing our lines can cost us a lot more than hurt pride. Having discovered and understood the specific needs and burning issues our prospect has, then this course will help any salesperson avoid dropping the ball and instead wowing their prospects with a high-impact, tailored and compelling case for purchase. This course will help participants: Prepare mentally and physically for stand-up presentations Use voice modulation and bullet-pointing to demand attention Avoid boring their prospects Master the do's and don'ts of PowerPoint Deal more effectively with technical hitches and prospect's interruptions Use eye contact and engagement to avoid prospects 'tuning out' Deploy best practice essentials for presenting with colleagues Steer through the toughest Q&A 1 Preparing your presentation Mindset Knowing your objective(s) Vocal warm-up techniques Assembling pre-agreed benefits Time management Room set-up Technical preparation 2 How to open your presentation Vocal energy Summary and agreement of prospect's needs How to have posture and confidence Use of humour What to do with those dreaded hands Confident v non-confident body language 3 How to get and keep people's attention Bullet pointing Linking benefits to specific, stated needs Practical exercise - formulating and delivering tailored benefits Being selective with features Third party reinforcement and case studies 'Watering the garden' eye contact technique Practical exercise - participants practise 'sharing out' eye contact to audience How to handle a prospect's negative body language Handling interruptions 4 Presenting in groups Credentialing all participants Role delineation for group presentations Edifying other participants' messages - do's and don'ts How to maintain energy when not speaking Practical exercise - good and bad practice when not speaking Teamwork in Q&A sessions How to hand over professionally 5 PowerPoint do's and don'ts Use of visual aids Good and bad PowerPoint slides How to make PowerPoint work for you Classic PowerPoint errors Avoiding and handling technical problems Good and bad flipchart practice 6 Closing and / or achieving next action steps Power of summary Good Q&A practice Handling objections Practical exercise - handling objections on one's feet Creating consensus among prospect panel What to do when prospects disagree with each other When to trial close How to close on next action steps 7 Wrap-up Key learning points from each participant Action steps to be implemented on next presentations

Fraud (In-House)

By The In House Training Company

Fraud should not happen, but it does. It can happen at the highest to lowest levels in an organisation. Recent surveys show that incidents of fraud are not decreasing. Fraud costs companies money and, perhaps even more importantly, reputational damage. The losers are not just the shareholders, suppliers, customers, etc, but society as a whole. This programme shows why frauds happen, how organisations put themselves at risk and what they can do to prevent it. This programme will help directors and others understand: The motives for committing fraud Directors' responsibilities for identifying and reporting fraud What types of frauds there are How frauds are perpetrated How they can be prevented How regulators deal with fraud Above all, the principal objective of this programme is to help make your organisation as secure as possible from the threat of fraud. 1 Motives for committing fraud - drivers of fraud Session objective: to understand why people might commit fraud Drivers of fraudulent behaviourAmbitionGreedTheftConceit? And more! 2 Accounting mechanisms that allow fraud Session objective: to review the elements of the accounting, internal control and management processes that allow creative accounting Income or liability? Asset or expense? Coding errors and misclassification Netting off and grossing up Off-balance sheet items 3 Structures that allow fraud Session objective: to consider company and trading structures that allow frauds to be perpetrated Group structures Trading structures Tax havens Importing and exporting 4 Interpretations and other non-compliance that allow fraud Session objective: to look at how creative interpretations of law and accounting practice may permit fraud The place of accounting standards Accounting policies Trading methods The place of auditing standards 5 Money laundering Session objective: to review what constitutes money laundering Types of money laundering Identifying laundering Preventing laundering 6 Preventing fraud - proper management structures Session objective: to review the place of proper corporate governance Corporate governance Company management structure Audit committees The place of internal audit 7 Preventing fraud - proper accounting Session objective: to review best accounting and auditing practice Accounting standards Internal accounting policies Adequacy of internal controls Internal audit 8 Preventing fraud - regulation Session objective: to look at how regulators aim to prevent fraud The regulatory environment Financial services regulation 9 Conclusion Course review Open forum Close 10 Course summary - developing your own cost action plan Group and individual action plans will be prepared with a view to participants identifying their cost risks areas and the techniques which can be immediately applied to improve costing and reduce costs

Overview Understand the role of corporate structure, dividends and equity indices in equity markets. Become familiar with the building blocks of repos / stock lending, futures and forwards – and how to use these products. Understand how to price, and risk manage equity swaps and dividend swaps. Gain experience in their uses in trading, corporate finance and portfolio management. Learn how to price equity options and the features that make them different from other asset classes, explore how to use these products for taking equity risk, yield enhancement and portfolio protection. Understand strategies designed to trade / hedge volatility using options. Who the course is for Risk management Finance Sales and trading Treasury Technology Financial Engineering Course Content To learn more about the day by day course content please click here To learn more about schedule, pricing & delivery options, book a meeting with a course specialist now

Search By Location

- Course Courses in London

- Course Courses in Birmingham

- Course Courses in Glasgow

- Course Courses in Liverpool

- Course Courses in Bristol

- Course Courses in Manchester

- Course Courses in Sheffield

- Course Courses in Leeds

- Course Courses in Edinburgh

- Course Courses in Leicester

- Course Courses in Coventry

- Course Courses in Bradford

- Course Courses in Cardiff

- Course Courses in Belfast

- Course Courses in Nottingham